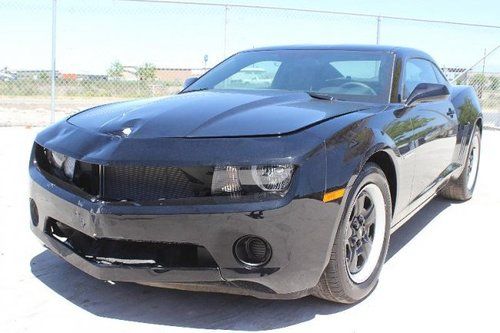

2012 Chevrolet Camaro 1lt Rs 15k Wrnty Xenon Wheels Sat Sharp Loaded on 2040-cars

Chesterland, Ohio, United States

Body Type:Coupe

Vehicle Title:Clear

Fuel Type:Flex Fuel Vehicle

For Sale By:Dealer

Make: Chevrolet

Model: Camaro

Warranty: Vehicle has an existing warranty

Mileage: 15,180

Sub Model: 2dr Cpe 1LT

Exterior Color: Blue

Interior Color: Black

Doors: 2

Number of Cylinders: 6

Engine Description: 3.6L V6 DIR DOHC 24V

Chevrolet Camaro for Sale

2013 chevrolet camaro ls coupe damaged salvage only 2k miles runs! loaded l@@k!!(US $10,900.00)

2013 chevrolet camaro ls coupe damaged salvage only 2k miles runs! loaded l@@k!!(US $10,900.00) 1969 ss camaro 396 x66 model super nice(US $60,000.00)

1969 ss camaro 396 x66 model super nice(US $60,000.00) 2012 chevy camaro lt rs auto sunroof rear cam hud 10k! texas direct auto(US $26,780.00)

2012 chevy camaro lt rs auto sunroof rear cam hud 10k! texas direct auto(US $26,780.00) 2010 chevy camaro 2ss rs 6-spd htd leather 20's 53k mi texas direct auto(US $25,980.00)

2010 chevy camaro 2ss rs 6-spd htd leather 20's 53k mi texas direct auto(US $25,980.00) 1991 chevrolet camaro 1le z28 5.7l tpi v8 automatic 6k miles

1991 chevrolet camaro 1le z28 5.7l tpi v8 automatic 6k miles 1970 chevrolet camaro base 5.7l

1970 chevrolet camaro base 5.7l

Auto Services in Ohio

Westerville Automotive ★★★★★

West Chester Autobody ★★★★★

Unique Auto Painting ★★★★★

Thrifty Mufflers ★★★★★

The Right Place Automotive ★★★★★

Superior Automotive & Truck Repair ★★★★★

Auto blog

Corvette Stingray Shooting Brake under consideration by Callaway [w/poll]

Mon, 18 Mar 2013Callaway has released a few renderings of a design study for a shooting brake version of the C7 Chevrolet Corvette Stingray. The company says it wants to create a long-roof version of America's sports car to offer buyers more interior room and a vehicle with "unique style." The company says it will use structural carbon fiber for the new body bits, which suggests the conversion shouldn't add too much more weight to the Corvette. Along with a few mechanical tweaks, the Callaway Corvette Stingray AeroWagon could breeze past the 200 miles per hour barrier.

Provided that they get enough interest, Callaway estimates they will be able to effect the changes on the Chevrolet for around $15,000, and says the conversion work should be available through its network of dealers. You can check out the brief press release below for more information, or head over to the Callaway site to plunk down a deposit - but before you do, we want to know... do you find this C7 wagon interesting? Vote in our poll below, then feel free to leave a few lines in Comments.

View Poll

Ram 1500 bests new F-150 in MT pickup shootout

Tue, Nov 25 2014Ford's 2015 Ford F-150 is a technological tour-de-force, what with its aluminum-intensive construction and its powerful and efficient new 2.7-liter EcoBoost engine option. But now that it's hit the market, it's time to get down to brass tacks and find out how just the latest F-150 actually stands up to its rivals in the hyper-competitive fullsize segment. Motor Trend is among the first to round up the Ford (in Lariat 2.7-liter 4X4 guise here) and put it up against the Ram 1500 Outdoorsman EcoDiesel 4x4 and 5.3-liter-equipped Silverado 1500 LTZ Z71 to find out how Dearborn's new-think truck measures up. The test put the trio through over 1,000 miles of tough driving in California and Arizona in a variety of conditions from just cruising around unladen to hauling a trailer. MT found all three trucks to be competent, but the most praise got heaped on the Ram and the Ford, with the Chevrolet falling a step behind its competitors in many tests. Among the Ford's most-liked features was its 2.7-liter, twin-turbo V6 that helped make the F-150 easily the quickest of the group, with some editors saying the engine felt about the same whether driving around with cargo in the bed or not. There was some minor turbo lag during acceleration while trailering, but that issue affected the Ram, too. The Ram's powertrain was lauded, as well. The EcoDiesel was torquey around town, and the 1500's combination of an eight-speed automatic and air suspension was judged to be the best of the lot. It was the most difficult to get into the bed, though. The Ram also won the fuel economy award by netting 20-miles-per-gallon city and 28-mpg highway in the test to beat its Environmental Protection Agency ratings of 19/27. The Ford's EcoBoost managed 17/22, one mpg off each from the EPA numbers, and using a lot of throttle really depleted its efficiency. As MT notes, however, it would take time for the diesel's mileage savings to pay off at the pump for these two trucks. In the end, the Ram just barely eked out the win, with the title partially earned because of "the Ford's unknown maintenance and aluminum repair costs," according to MT. Go check out the full comparison to read all of the details, then let us know what you think in Comments.

GM warning 800,000 owners that their cars may need oil changes more frequently than they say

Fri, 05 Apr 2013The days of changing your engine oil every 3,000 miles are long gone thanks to most cars having automatic oil monitoring systems, but about 800,000 General Motors vehicles apparently have incorrect monitoring software that is leading to premature engine component wear. According to Autoweek, certain 2010-2012 Buick LaCrosse, Regal, Chevrolet Equinox and GMC Terrain models equipped with 2.4-liter four-cylinder engines could be going too long in between oil changes resulting in a higher-than-normal number of warranty claims for the engine's balance chain. The balance chain links the balance shaft to the crankshaft, and a worn one can produce higher noise levels.

As a fix, GM dealers will be reprogramming the software for the monitors in an effort to reduce the interval between oil changes, which varies based on driving habits and conditions. Through February 2015, the software update will be done at no cost to vehicle owners, but since this is not a recall, after that point, it will be up to the discretion of dealers as to whether or not they will charge for the service. What isn't immediately clear is whether GM plans on giving assistance to out-of-warranty customers who are experiencing engine issues from the worn chain.