Chevrolet Nova for Sale

* 1972 nova * solid roller * no rust * new matte finish black paint(US $14,500.00)

* 1972 nova * solid roller * no rust * new matte finish black paint(US $14,500.00) 1967 chevy nova 2dr 6 speed

1967 chevy nova 2dr 6 speed Beautiful 1964 chevy ii nova sport 2 dr hardtop- 327 v8 / 4 speed - triple black(US $13,500.00)

Beautiful 1964 chevy ii nova sport 2 dr hardtop- 327 v8 / 4 speed - triple black(US $13,500.00) 1966 chevrolet nova - tuxedo black - roller cam aluminum heads 383 stroker!

1966 chevrolet nova - tuxedo black - roller cam aluminum heads 383 stroker! 1964 chevy ii nova classic(US $4,500.00)

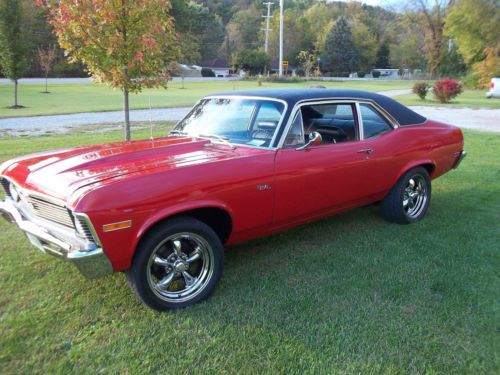

1964 chevy ii nova classic(US $4,500.00) 1962 chevrolet chevy nova - red - 2 door

1962 chevrolet chevy nova - red - 2 door

Auto blog

2014 Chevrolet C7 Corvette wastes no time zooming into Jay Leno's Garage

Thu, 24 Jan 2013Where else would you expect the 2014 Chevrolet Corvette Stingray to show up first? Although this time it isn't exactly in Jay Leno's Garage, Leno instead playing an away game at Brown's Classic Auto in Scottsdale, Arizona. Nor does Leno drive the car, instead taking an 11-minute walkaround of the new American sports car with General Motors design head Ed Welburn, the same man who recently brought by a string of classic Corvettes to the talk show host's California compound.

It is, admittedly, a love-fest for the American sports car now featuring 450 horsepower and 450 pound-feet of torque, but one that also features admissions about previous Corvette seats like "they were kinda rough," and the explanation that labeling the coupe "Stingray" means not having to call it "the base Corvette." On top of that, Welburn also explains the proper application of the term "dashboard." You can watch it all in the video below.

Chevy finishes restoration of damaged 1 millionth Corvette

Fri, Sep 4 2015When a sinkhole at the National Corvette Museum devoured eight, rare examples of the iconic American sports car last year, some of the victims emerged better than others. While damaged, the 2009 Corvette ZR1 Blue Devil was able to drive out under its own power, making for a fairly straightforward restoration. Meanwhile, the one-millionth 'Vette came out looking like a pancake. Bringing the convertible back to perfection has taken four months and 1,200 man-hours, but the milestone car is finally on display again. After being a brief exhibit at the National Corvette Museum, the millionth 'Vette was moved to the General Motors Design Center. There, a 30-person team started on the difficult restoration. "When we disassembled it, we found that each employee involved in building it had signed a part of the car, which was fantastic and moving to see," said GM executive Mark Reuss. Therefore, the team tried to retain as many original parts as possible. The damage was extensive, and repairs included straightening the front sub-frame damage, patching the seats, and carefully restoring the dashboard pad to maintain the signatures below. The hood, front fascia, and side sills were replaced with parts from a donor vehicle. To keep the 'Vette perfect, the team scanned the names and put them on the new components. In one case, they even went back to an original employee to sign a replacement part. Surprisingly, the engine and transmission were fine. With the work done, the National Corvette's Museum's revived exhibit is nearly complete. Five of the other cars aren't being restored, and the museum is bringing the 1962 Corvette back to life. <p>Your browser does not support iframes.</p> Chevrolet Fulfills 1 Millionth Corvette Restoration Pledge Sinkhole-damaged milestone returns to National Corvette Museum 2015-09-03 BOWLING GREEN, Ky. – After more than four months and 1,200 man-hours of painstaking craftsmanship, restoration of the milestone 1 millionth Corvette – a white 1992 convertible – is complete. It was unveiled today at the National Corvette Museum, where it returns as part of the permanent exhibit. The car was damaged on Feb. 12, 2014, when it and seven other rare Corvettes tumbled into a sinkhole that opened beneath the museum's Skydome area. Chevrolet pledged to restore it.

With only 246 Volts sold in Australia, Holden not getting next-gen model

Tue, Apr 28 2015The Chevrolet Volt has not been the resounding success General Motors hoped for here in the United States. But it's fortunes in Chevy's home country are nothing compared to how poorly it's done down under. Only 246 Volts have been sold in Australia, where the car is branded as a Holden, since its debut in 2012. That's not just a bad showing – it's an absolute disaster. According to Motoring.com.au, it was the Volt's astonishing $60,000 price tag, combined with a lack of interest from Aussie drivers, that killed the car's chances. What's fascinating about this development, though, is that it doesn't necessarily seem to be Holden that's pulling the plug. Instead, it's the Volt's Hamtramck, MI factory, which is preparing to shift into production of the second-generation model that seems to be taking the blame. According to Motoring, the plant confirmed that it will only build the Gen 2 plug-in in left-hand-drive form, basically ruling out a model for Australia. "Electric and hybrid vehicles haven't taken off in Australia," Holden's director of communications, Sean Poppitt, told Motoring. "Considering the lack of infrastructure, the lack of government incentives, the large distances between cities, it's a tough sell." The death of the right-hand drive Volt won't be the only loss of business in Hamtramck. Opel has already confirmed that it will drop the plug-in's European fraternal twin, the Ampera, while the next-gen Chevy won't make the trip across the pond either. Related Video: