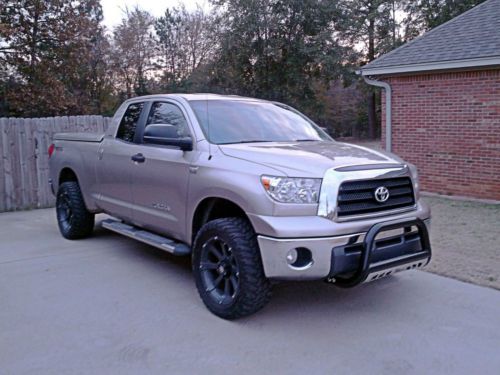

2007 Toyota Tundra Sr5 Extended Crew Cab Pickup 4-door 4.7l on 2040-cars

Lugoff, South Carolina, United States

|

This is our third Tundra, it's in very good shape and well maintained. A little wear & tear, a few small scratches (see photos). Includes running boards, bed rails and tool box. Full payment is due within 10 days. Buyer is responsible for shipping or pick up of the vehicle. More photos by requests. Thanks for looking! |

Toyota Tundra for Sale

2013 toyota tundra limited custom lifted truck(US $46,980.00)

2013 toyota tundra limited custom lifted truck(US $46,980.00) 2003 toyota tundra sr5 extended cab pickup 4-door 4.7l ,stepside bed,trd

2003 toyota tundra sr5 extended cab pickup 4-door 4.7l ,stepside bed,trd 2007 toyota tundra trd sr5 double cab(US $18,900.00)

2007 toyota tundra trd sr5 double cab(US $18,900.00) 1-owner ! carfax and autocheck no accidents !, service records,(US $16,999.00)

1-owner ! carfax and autocheck no accidents !, service records,(US $16,999.00) 00 toyota tundra 4x4 sr5 extended cab 4dr 4.7l 4wd.remote start , runs great(US $7,500.00)

00 toyota tundra 4x4 sr5 extended cab 4dr 4.7l 4wd.remote start , runs great(US $7,500.00) 2013 toyota tundra regular cab pickup truck lifted 7.5" 5.7l v8 4x4 trd off road

2013 toyota tundra regular cab pickup truck lifted 7.5" 5.7l v8 4x4 trd off road

Auto Services in South Carolina

Village Motors Inc ★★★★★

Shell Rapid Lube & Service Center ★★★★★

Santee Lake Service Center Inc ★★★★★

S & S Tire Inc ★★★★★

Richbourg`s Auto Electric Service ★★★★★

Randy`s Automotive ★★★★★

Auto blog

2015 Toyota Camry Hybrid

Mon, 22 Sep 2014Toyota offers many flavors of its refreshed 2015 Camry, but those who choose to lower their operating cost-per-mile, squeeze 500-plus miles out of each tank of fuel or run a very efficient and reliable sedan in their taxi fleets will only be interested in one: the Camry Hybrid.

The exterior of the 2015 Camry Hybrid is nearly indistinguishable from its gasoline-only counterparts, with the same all-new sheetmetal and bumpers. The Hybrid is offered in LE, SE and XLE trims, meaning customers are offered base, sport or luxury configurations, respectively.

While Toyota expended quite a bit of effort resculpting and improving the 2015 Camry Hybrid, one area it didn't touch was the powertrain - it is virtually identical to last year's model (just like the gas version). Under the hood is a 2.5-liter Atkinson cycle four-cylinder gasoline engine (156 horsepower and 156 pound-feet of torque) and an electric tractive motor (141 horsepower and 199 pound-feet of torque). Combined, and running through Toyota's unique Hybrid Synergy Drive electronic continuously variable transmission, the two produce 200 horsepower (Toyota does not list a combined torque figure, and we've asked for clarification). A 1.6 kilowatt-hour nickel-metal-hydride battery, packaged behind the rear seats, provides energy storage.

Watch a Toyota Highlander ram a house, twice

Mon, 15 Apr 2013Toyota has had plenty of problems in recent years due to claims of unintended acceleration, and now here's a video that actually catches such a claim on video. The driver of this 2010-2013 Toyota Highlander claims that the crossover's accelerator got stuck causing the vehicle to slam into the house twice, and resulting in damage to the Highlander, the house and two vehicles inside the garage. While we don't know when this accident took place, the video was uploaded to YouTube back in January.

It is impossible to determine what actually happened in this video, but what we do know is that a security camera captures the Highlander slowly pulling into the driveway before it lunges forward slamming into the garage. With the tires squealing and metal crunching, the driver then shifts between reverse and drive a couple times causing even more property damage before spinning out in the street and finally being able to shift into Park. Scroll down to see the video for yourself. Whether unintended acceleration or driver error, this was undoubtedly a harrowing ordeal.

Toyota ready to get dirty with new TRD Pro Series

Thu, 06 Feb 2014To the general public, Toyota is often thought of as a maker of bland but dependable cars, crossovers and SUVs that get their owners and a whole herd of whatever from Point A to Point B. Generally speaking, they're fuel efficient, comfortable and affordable. What the general public may not realize, however, is that Toyota enjoys a very strong history of going off road, too. The legendary Land Cruiser arguably established the trend, helping explore remote parts of the globe, while various guerilla warfare outfits and world military branches have unwittingly joined up with the boys from Top Gear to help cement the Hilux pickup's reputation for invincible performance. Now, though, Toyota is launching a new line of trucks and SUVs in the US that are even more explicitly targeted at hitting the trails. Meet the TRD Pro Series.

Featuring the 4Runner, Tacoma and Tundra, each Pro Series vehicle features TRD-tuned springs with Bilstein shocks, a TRD front skid plate, a TRD shifter, black wheels, branded floor mats and a "TOYOTA" grille badge, the latter of which harkens back to classic models. TRD Pro Series vehicles will be offered in the new Inferno paint color shown above, as well as Black and Super White.

The Tundra benefits from softer TRD springs that also provide a two-inch lift and a better ride in the rough, while the truck itself rides on 18-inch wheels with Michelin ORP tires. Each truck gains an extra two inches of wheel travel in front and 1.25 inches in back, while a TRD dual exhaust should generate a nicer sound than the trucks's standard V8 engine. Finally, a unique interior with red contrast stitching freshen up the cabin. We wouldn't go so far as to call this a Ford F-150 SVT Raptor fighter - far from it, in fact - but it's a bit more off-road oriented than your average pickup.