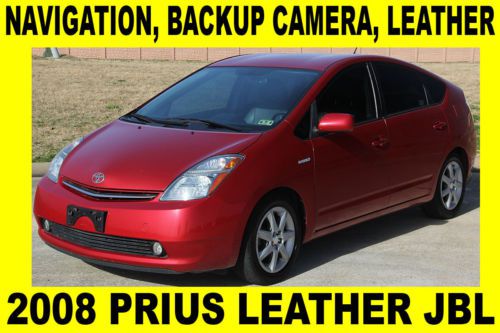

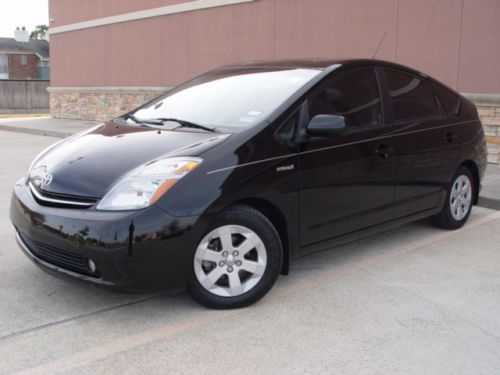

2008 Toyota Prius Navigation,backup Camera,leather,jbl,ipod,clean Tx Title on 2040-cars

Houston, Texas, United States

Toyota Prius for Sale

2005 toyota prius hybrid 1owner nav prem cloth alloys keyless go spoiler clean(US $8,480.00)

2005 toyota prius hybrid 1owner nav prem cloth alloys keyless go spoiler clean(US $8,480.00) 2013 toyota prius c model 3 no reserve hybrid sunroof nav 23k perfect org owner(US $18,995.00)

2013 toyota prius c model 3 no reserve hybrid sunroof nav 23k perfect org owner(US $18,995.00) Fog lights, backup camara, well maintained and serviced regularly 93000miles(US $13,500.00)

Fog lights, backup camara, well maintained and serviced regularly 93000miles(US $13,500.00) Touring xenon lights back up camera keyless go jbl sound cd ch. fog lights(US $9,490.00)

Touring xenon lights back up camera keyless go jbl sound cd ch. fog lights(US $9,490.00) 2007 toyota prius with bluetooth, jbl sound, xenon and fogs, new pa inspection(US $6,995.00)

2007 toyota prius with bluetooth, jbl sound, xenon and fogs, new pa inspection(US $6,995.00) 12k one 1 owner low miles 2013 toyota prius c hybrid cloth seats pwr windows

12k one 1 owner low miles 2013 toyota prius c hybrid cloth seats pwr windows

Auto Services in Texas

WorldPac ★★★★★

VICTORY AUTO BODY ★★★★★

US 90 Motors ★★★★★

Unlimited PowerSports Inc ★★★★★

Twist`d Steel Paint and Body, LLC ★★★★★

Transco Transmission ★★★★★

Auto blog

VW Q3 Financial Woes, 2015 Tokyo Motor Show | Autoblog Minute

Sat, Oct 31 2015Consumer Reports pulls its Tesla recommendation, the U.S. Copyright Office offers a ruling affecting car owners, VW gets hit hard with third quarter losses, and lots of exciting news from Tokyo. Autoblog's Senior editor Greg Migliore reports on this Autoblog Minute Weekly Recap. Tokyo Motor Show Mazda Subaru Suzuki Tesla Toyota Concept Cars Autoblog Minute Videos Original Video Tokyo 2015

Toyota will bring Lexus-based Platform 3.0 autonomous vehicle to CES

Thu, Jan 4 2018The Toyota Research Institute says it will bring its next-generation Platform 3.0 automated driving vehicle to CES next week, an autonomous test car that is notable for incorporating the sensors and cameras into the body, rather than as ungainly attachments, and with the spinning LIDAR rooftop sensor replaced by a more sleek panel of sensors. Platform 3.0 is built on a Lexus LS600hL. Toyota Research Institute says it enlisted CALTY Design Research in Ann Arbor, Mich. and engineers at Toyota's nearby North America R&D center to conceal the equipment. As a result, Platform 3.0 gets a new rooftop weather and temperature proof panel, which it says was inspired by off-road motorcycle helmets, integrated into the available space in the sunroof compartment to minimize height. It's also embellished with chrome trim along the side, where it meets the roofline, and the rear swoops down to integrate with the LS's contour lines. The team also managed to consolidate computational electronics and wiring into a small box in the trunk. Toyota says the Platform 3.0 is one of the most perceptive autonomous test vehicles on the road today, with a design makes the test vehicle easy to build at scale. It gets a Luminar LIDAR system boasting a 200-meter, 360-degree range (the previous version only tracked the forward direction), enabled by four high-res LIDAR scanning heads that help it better see dark objects. Shorter-range LIDAR sensors feature low on all four sides of the vehicle, one on each front quarter panel and on the front and rear bumpers, to detect low-level and smaller objects, like children or road debris. Production begins this spring at the Toyota Motor North America R&D headquarters at low volumes to allow for flexibility, given the rapid rate of development of Toyota's autonomous test platforms. Some will be assembled using Toyota's Guardian dual-cockpit control layout to allow for transferring control between a human test driver and the automated system while keeping the driver as a backup, while the single-cockpit, fully autonomous Chauffeur mode will be shown at CES starting Jan. 9.Related Video: This content is hosted by a third party. To view it, please update your privacy preferences. Manage Settings. Least favorite vehicles of 2017

How Toyota's 100-year textile history influenced FCV hydrogen fuel cell car

Thu, Sep 11 2014Turns out, Toyota had a surprising ace in the hole when it came to building the new fuel tanks for the FCV hydrogen fuel cell car, which is coming next year. Well before Toyota became the Toyota Motor Company, it was the Toyota Industries Corporation and it made textile looms. This is important because the main structure of the hydrogen tank is wound carbon fiber. When Toyota set out to increase the strength of the tanks to hold hydrogen stored at 10,000 psi (up from 5,000 in the previous tanks), it was able to draw on its 100-year-old history as it designed its car of the future. "A lot of that textile experience came back when we did the tank wrapping." – Justin Ward "We have a lot of experience with textiles," Justin Ward told AutoblogGreen at the 21st World Congress on Intelligent Transport Systems (ITS) in Detroit this week, "and a lot of that textile experience came back when we did the tank wrapping." On top of being able to hold the higher-pressure hydrogen, Toyota's first attempt to build its own hydrogen tank was six times faster than the industry standard, so it saved time and money as well as working better. The company will also be able to inspect its own tanks. Ward is the general manager of powertrain system control at the Toyota Technical Center and hydrogen vehicles are something he knows a lot about. The reason for the stronger, 10,000-psi tanks is because the 5,000-psi tanks only offered around 180-200 miles of range, even with four tanks in the early $129,000 FCHV Highlander hydrogen prototypes. The FCV only has two, but they will able to deliver the 300-mile range that customers told Toyota they wanted. Dropping the number of tanks not only obviously reduced the cost for the tanks themselves but also the number of valves and hoses and other components you need. Despite the benefits of higher compression, going much higher doesn't make sense. 10,000 psi is the "natural progression," Ward said, because "you start to bump up against compression inefficiencies." Think of an air compressor. When hydrogen is produced at a wastewater treatment plant or a reforming site, Ward said, is it at around ambient pressure (14 psi). That has to be raised, using compressors, all the way to 10,000 psi. "That takes energy," Ward said, "and every doubling of pressure adds another doubling of energy needed, so it starts to add up pretty fast if you go too high." Component specifications are also fine at 10,00 psi, but more difficult at higher levels.