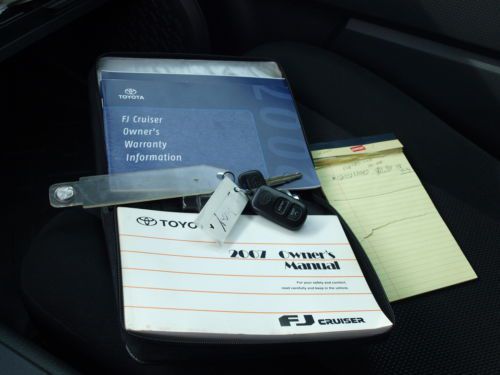

2007 Fj Cruiser Blue Automatic 4x4 Suv 6cyl 4.0l on 2040-cars

Olyphant, Pennsylvania, United States

Toyota FJ Cruiser for Sale

2010 toyota fj cruiser 2wd 4-door 4.0l

2010 toyota fj cruiser 2wd 4-door 4.0l 2007 toyota fj cruiser trd special edition sport utility 4-door 4.0l(US $23,000.00)

2007 toyota fj cruiser trd special edition sport utility 4-door 4.0l(US $23,000.00) Toyota fj cruier 4x4 suv off road custom wheels tires auto tow low price

Toyota fj cruier 4x4 suv off road custom wheels tires auto tow low price 2007 toyota

2007 toyota 14 custom fj lifted 5dr 4x4 wagon new 4.0l carbon fiber 4 liter v6 dohc engine

14 custom fj lifted 5dr 4x4 wagon new 4.0l carbon fiber 4 liter v6 dohc engine 2007 toyota fj cruiser 4wd damaged salvage runs!! priced to sell export welcome!(US $8,450.00)

2007 toyota fj cruiser 4wd damaged salvage runs!! priced to sell export welcome!(US $8,450.00)

Auto Services in Pennsylvania

West Penn Collision ★★★★★

Wallace Towing & Repair ★★★★★

Truck Accessories by TruckAmmo ★★★★★

Town Service Center ★★★★★

Tom`s Automotive Repair ★★★★★

Stottsville Automotive ★★★★★

Auto blog

An early gas-electric hybrid was developed by...Exxon?

Tue, Oct 25 2016We're not sure which aspect of Exxon's 1970s-era efforts to develop advanced and electrified powertrains is the most ironic. There's Exxon, that of the Valdez oil spill infamy, being on the leading edge of hybrids and electric vehicles. There's a boat-like Chrysler Cordova getting 27 miles per gallon. And there's the central role a Volkswagen diesel engine plays in that hybrid development. It's all outlined in an article (linked above) by Inside Climate News, and it's an amusing read. Flush with cash and fearing what it thought was peak oil production in the 1970s, Exxon funded a host of new ventures divisions geared to find alternatives to gas-powered powertrains. In the early 1970s, Exxon lured chemist M. Stanley Whittingham to develop what would become a prototype of a lithium-ion rechargeable battery. Then, in the late 1970s, Exxon pioneered the concept of using an alternating-current (AC) motor as part of a gas-electric hybrid vehicle. The company retrofitted a Chrysler Cordova (yes, that's the model Ricardo Montalban used to hawk) with a powertrain that combined 10 Sears Die-Hard car batteries, an alternating current synthesizer (ACS), a 100-horsepower AC motor, and, yes, a four-cylinder 50-horsepower Volkswagen diesel engine. The result was a rather large two-door sedan that got an impressive 27 mpg. And while US automakers didn't see the potential in the early concept, in 1980 Exxon and Toyota began collaborating on a project that would involve retrofitting a Toyota Cressida with a hybrid engine. That car was completed in 1981, and may have been one of the seeds that eventually helped sprout the concept of the Toyota Prius. Soon after rebuilding the Cressida, Exxon would get out of the advanced-powertrain-development business, as oil prices began to fall in the early 1980s, spurring cost-cutting measures. Cry no tears for the Exxon, though, as what's now known as ExxonMobil is the largest US oil company. Related Video: News Source: Inside Climate NewsImage Credit: Spencer Platt/Getty Images Green Read This Chrysler Toyota Electric Hybrid battery

Automakers not currently promoting EVs are probably doomed

Mon, Feb 22 2016Okay, let's be honest. The sky isn't falling – gas prices are. In fact, some experts say that prices at the pump will remain depressed for the next decade. Consumers have flocked to SUVs and CUVs, reversing the upward trend in US fuel economy seen over the last several years. A sudden push into electric vehicles seems ridiculous when gas guzzlers are selling so well. Make hay while the sun shines, right? A quick glance at some facts and figures provides evidence that the automakers currently doubling down on internal combustion probably have some rocky years ahead of them. Fiat Chrysler Automobiles is a prime example of a volume manufacturer devoted to incremental gains for existing powertrains. Though FCA will kill off some of its more fuel-efficient models, part of its business plan involves replacing four- and five-speed transmissions with eight- and nine-speed units, yielding a fuel efficiency boost in the vicinity of ten percent over the next few years. Recent developments by battery startups have led some to suggest that efficiency and capacity could increase by over 100 percent in the same time. Research and development budgets paint a grim picture for old guard companies like Fiat Chrysler: In 2014, FCA spent about $1,026 per car sold on R&D, compared with about $24,783 per car sold for Tesla. To be fair, FCA can't be expected to match Tesla's efforts when its entry-level cars list for little more than half that much. But even more so than R&D, the area in which newcomers like Tesla have the industry licked is infrastructure. We often forget that our vehicles are mostly useless metal boxes without access to the network of fueling stations that keep them rolling. While EVs can always be plugged in at home, their proliferation depends on a similar network of charging stations that can allow for prolonged travel. Tesla already has 597 of its 480-volt Superchargers installed worldwide, and that figure will continue to rise. Porsche has also proposed a new 800-volt "Turbo Charging Station" to support the production version of its Mission E concept, and perhaps other VW Auto Group vehicles. As EVs grow in popularity, investment in these proprietary networks will pay off — who would buy a Chevy if the gas stations served only Ford owners? If anyone missed the importance of infrastructure, it's Toyota.

Toyota retires robots in favor of humans to improve automaking process

Sat, 12 Apr 2014Mitsuru Kawai is overseeing a return to the old ways at Toyota factories throughout Japan. Having spent 50 years at the Japanese automaker, Kawai remembers when manual skills were prized at the company and "experienced masters used to be called gods, and they could make anything." Company CEO Akio Toyoda personally chose Kawai to develop programs to teach workers metalcraft such as how to forge a crankshaft from scratch, and 100 workstations that formerly housed machines have been set aside for human training.

The idea is that when employees personally understand the fabrication of components, they will understand how to make better machines. Said Kawai, "To be the master of the machine, you have to have the knowledge and the skills to teach the machine." Lessons learned by the newly skilled workers have led to shorter production lines - in one case, 96percent shorter - improved parts production and less scrap.

Taking time to give workers the knowledge to solve problems instead of merely having them "feed parts into a machine and call somebody for help when it breaks down," Kawai's initiative is akin to that of Toyota's Operations Management Consulting Division, where new managers are given a length of time to finish a project but not given any help - they have to learn on their own. It's not a step back from Toyota's quest to build more than ten million cars a year; it's an effort to make sure that this time they don't sacrifice quality while making the effort. Said Kawai, "We need to become more solid and get back to basics."