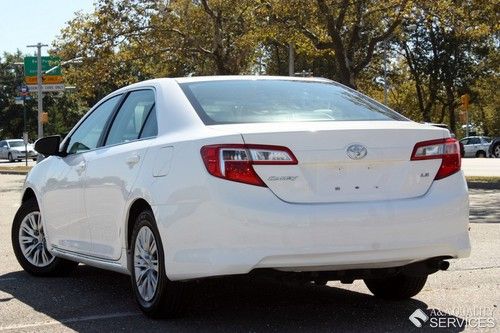

Toyota Camry for Sale

2003 toyota camry le sedan 4-door 2.4l(US $5,999.00)

2003 toyota camry le sedan 4-door 2.4l(US $5,999.00) 1999 toyota camry le sedan 4-door 2.2l

1999 toyota camry le sedan 4-door 2.2l 1996 toyota camry wagon, 88k miles, must see

1996 toyota camry wagon, 88k miles, must see 2002 toyota camry se

2002 toyota camry se Le low miles 4 dr sedan automatic gasoline 2.5l l4 fi dohc 16v magnetic gray met(US $16,973.00)

Le low miles 4 dr sedan automatic gasoline 2.5l l4 fi dohc 16v magnetic gray met(US $16,973.00) 4dr sdn i4 auto l toyota camry 4 door fwd sedan i4 automatic l model new automat

4dr sdn i4 auto l toyota camry 4 door fwd sedan i4 automatic l model new automat

Auto blog

Toyota creates GT86 concept inspired by Initial D

Wed, Jun 29 2016Everyone has a favorite movie or TV car of their youths. The love of these cars can ignite a lifelong passion for automobiles. Some lust for the sharp, stainless steel DeLorean DMC-12 from Back to the Future or the decked-out Aston Martin DB5 from Goldfinger. For anime and manga fans, it's the panda-colored Toyota AE86 Sprinter Trueno from the Initial D manga and anime series. Toyota, recognizing the significance of the that car, meticulously reimagined it for a modern audience, basing it on the UK market GT86. The GT86, sold in the United States as the Scion FR-S and soon to be rebadged as the Toyota 86, is considered by some to be the spiritual successor to the rear-wheel-drive AE86 Corolla from the 1980s. Both are reasonably affordable, lightweight cars with a propensity for oversteer. The original AE86 from Initial D was a highly modified but realistic drift machine. The amazing feats of that tofu delivery car as it raced everything from Mazda RX-7s to a Honda S2000 turned the little Toyota into a cult icon. That AE86 itself was inspired by the personal vehicle of Japanese racing driver Keiichi Tsuchiya. Tsuchiya served as both an inspiration and supervisor for Initial D. Many of the modifications on the Initial D car, like the TRD carbon-fiber hood and Fujitsubo exhaust, car were exactly the same as Tsuchiya's real-life vehicle. Toyota is no stranger to crafting modern incarnations of classic vehicles. Last year the company created a Back to the Future Tacoma. Toyota's Initial D concept car uses the same parts wherever possible. Like the original, it has a carbon-fiber hood, Fujitsubo exhaust, and black Watanabe F8 wheels. The suspension, lights, and body have all been modified. Even small details like the engine cover and door handles were modified to recall the fictional car. The end result is a fantastic creation that pays great homage to the original. Toyota went as far as hiring UK manga artist Sonia Leong to design a series of backdrops that place the car in the same action shots as the original series. While this one-off vehicle is just a concept, most of the parts are available to purchase for fans who may be inspired to create their own version. Toyota's concept will be on display at various motoring shows across the UK this summer. Related video: Featured Gallery Toyota Initial D GT86 TV/Movies Scion Toyota Coupe toyota gt86 toyota 86

Toyota Me.We concept is a multifunction Tupperware car [w/video]

Wed, 24 Apr 2013Not to be outdone by the Renault Twin'Z concept penned by Welsh designer Ross Lovegrove, Toyota has partnered up with French designer Jean-Marie Massaud to create the 2013 Toyota Me.We Concept. Unveiled at Le Rendez-vous Toyota in Paris, the Me.We Concept is an attempt to imagine a car that can be appreciated by owners across a wide variety of lifestyles while being courteous to the environment, too.

From a "Me" perspective, the concept is highly customizable with removable body panels, and even though it might look like just a small hatchback from the outside, Toyota claims it can also be used as a pickup (with an extendable rear panel), a convertible (with a neoprene roof panel) and even an off-road vehicle. As for the "We" part of the car, it's a fully electric vehicle with individual in-wheel motors and a battery pack mounted under the load floor. The concept has a weight of around 1,600 pounds kept low thanks to an aluminum chassis, but it also features renewable bamboo wood for the floor in addition to the fully recyclable polypropylene exterior body panels. Scroll down to see more in an official video and to check out Toyota's official press release.

How Toyota's 100-year textile history influenced FCV hydrogen fuel cell car

Thu, Sep 11 2014Turns out, Toyota had a surprising ace in the hole when it came to building the new fuel tanks for the FCV hydrogen fuel cell car, which is coming next year. Well before Toyota became the Toyota Motor Company, it was the Toyota Industries Corporation and it made textile looms. This is important because the main structure of the hydrogen tank is wound carbon fiber. When Toyota set out to increase the strength of the tanks to hold hydrogen stored at 10,000 psi (up from 5,000 in the previous tanks), it was able to draw on its 100-year-old history as it designed its car of the future. "A lot of that textile experience came back when we did the tank wrapping." – Justin Ward "We have a lot of experience with textiles," Justin Ward told AutoblogGreen at the 21st World Congress on Intelligent Transport Systems (ITS) in Detroit this week, "and a lot of that textile experience came back when we did the tank wrapping." On top of being able to hold the higher-pressure hydrogen, Toyota's first attempt to build its own hydrogen tank was six times faster than the industry standard, so it saved time and money as well as working better. The company will also be able to inspect its own tanks. Ward is the general manager of powertrain system control at the Toyota Technical Center and hydrogen vehicles are something he knows a lot about. The reason for the stronger, 10,000-psi tanks is because the 5,000-psi tanks only offered around 180-200 miles of range, even with four tanks in the early $129,000 FCHV Highlander hydrogen prototypes. The FCV only has two, but they will able to deliver the 300-mile range that customers told Toyota they wanted. Dropping the number of tanks not only obviously reduced the cost for the tanks themselves but also the number of valves and hoses and other components you need. Despite the benefits of higher compression, going much higher doesn't make sense. 10,000 psi is the "natural progression," Ward said, because "you start to bump up against compression inefficiencies." Think of an air compressor. When hydrogen is produced at a wastewater treatment plant or a reforming site, Ward said, is it at around ambient pressure (14 psi). That has to be raised, using compressors, all the way to 10,000 psi. "That takes energy," Ward said, "and every doubling of pressure adds another doubling of energy needed, so it starts to add up pretty fast if you go too high." Component specifications are also fine at 10,00 psi, but more difficult at higher levels.