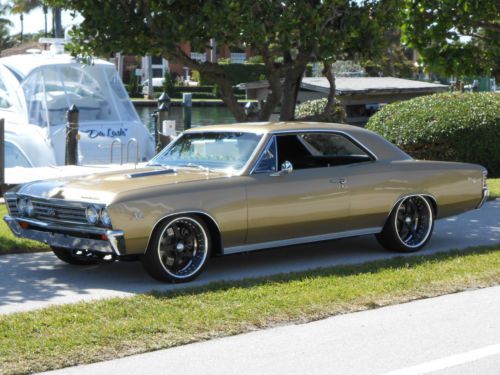

1967 Chevrolet Chevelle Ss Resto Mod 427 Frame Off Restoration Immaculate on 2040-cars

Boca Raton, Florida, United States

Chevrolet Chevelle for Sale

1964 custom chevelle created by legends a 30 year pro builder big block 2 carbs

1964 custom chevelle created by legends a 30 year pro builder big block 2 carbs 66 real 138 ss 396 4 speed a/c 12 bolt ready to enjoy!!

66 real 138 ss 396 4 speed a/c 12 bolt ready to enjoy!! Very rare! solid 69 super sport convertible! 396 4 speed tach disc brakes video

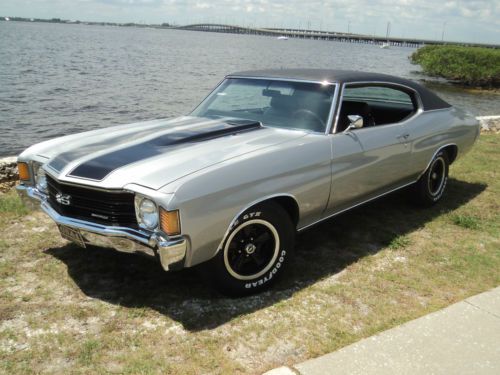

Very rare! solid 69 super sport convertible! 396 4 speed tach disc brakes video 1972 chevrolet chevelle ss replica, 454ci - automatic, buckets, new paint

1972 chevrolet chevelle ss replica, 454ci - automatic, buckets, new paint 1966 chevy chevelle super sport, concourse, 34k miles, #'s , a/c, please read !(US $49,500.00)

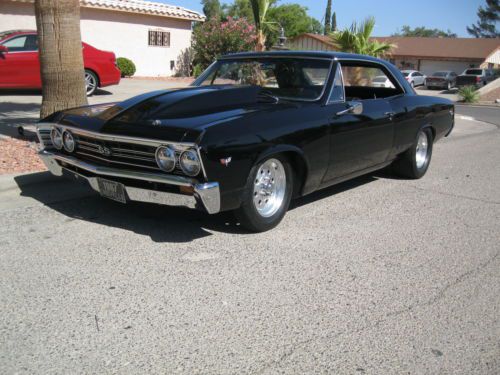

1966 chevy chevelle super sport, concourse, 34k miles, #'s , a/c, please read !(US $49,500.00) 1967 chevrolet chevelle ss pro street rod 4 speed muncie m21 66 69 70 65(US $32,000.00)

1967 chevrolet chevelle ss pro street rod 4 speed muncie m21 66 69 70 65(US $32,000.00)

Auto Services in Florida

Y & F Auto Repair Specialists ★★★★★

X-quisite Auto Refinishing ★★★★★

Wilt Engine Services ★★★★★

White Ford Company Inc ★★★★★

Wheels R US ★★★★★

Volkswagen Service By Full Throttle ★★★★★

Auto blog

GM delays 3.0-liter Duramax diesel in Silverado and Sierra pickups

Thu, May 23 2019Stricter testing protocols around the world are making it harder for automakers to predict launch timelines. GM is the latest to get caught in emissions nettles, the Detroit carmaker forced to delay the launch of its new Duramax 3.0-liter inline-six diesel for the Chevrolet Silverado 1500 and GMC Sierra 1500. That's what company reps told dealers in a memo seen by Automotive News this week. Dealers and buyers had been promised the Flint, Mich.-built oil-burner in early 2019, but AN wrote that the EPA certification hiccup has turned into a "slight delay." A GM spokesman told Motor1, "[We] did not attribute [the delay] to a single entity, as the truth is this is a collaborative effort between GM and several government entities. We will make the 2020MY Duramax available for dealers orders soon, and expect to deliver the first trucks to customers soon after emissions testing is complete." We know the new 3.0-liter Duramax diesel has 277 horsepower and 460 pound-feet of torque, outdoing Ford's 3.0-liter PowerStroke diesel by 27 hp and 20 lb-ft. But without final EPA paperwork, GM can't release the numbers that will show how the two engines stack up when considering fuel economy and tow ratings. The certification process has been sticky for a few other makers of late, especially since the Volkswagen Group situation in 2015. BMW had to delay the launch of four diesel models in 2016 over EPA testing. The new Ram 1500 dribbled out in a trickle last year for reasons thought to deal with EPA testing, coming as it did a year after the EPA investigated Ram's EcoDiesel engines in 2017 and 2018. More recently, WLTP testing in Europe caught out just about every automaker over there. Since we're almost halfway through 2019, the delay until the 2020 model year is only a few months. Still, GM told dealers to cancel any orders for the engine for this model year. Dealers will need to resubmit the orders once opening begins, but GM hasn't said when production will begin other than "soon." The company said that it will offer 2020-model-year replacement vehicles to customers and dealers. If prices hold into the next model year, the 2020 Silverado 1500 and Sierra 1500 with the inline-six diesel will come at a $3,890 premium over the 2.7-liter turbo four-cylinder, and a $2,495 premium over the 5.3-liter V8.

2016 Chevy Cruze is lighter, loaded [UPDATE]

Thu, Jun 25 2015UPDATE: Live photos and video of the reveal have been added at the end of the story. Chevrolet revealed the second-generation Cruze Wednesday, promising a larger, more efficient car that drives better than the sedan it replaces. We're particularly excited about the new turbocharged, 1.4-liter four-cylinder engine, which makes 153 horsepower, an upgrade from the outgoing 1.8-liter naturally aspirated engine's 138 hp. Torque climbs even more significantly, from 148 pound-feet to 177 in the new mill. Peak twist can be called up between 2,000 and 4,000 rpm, which should make performance easy to access. Combined with a lighter architecture that slashes the Cruze's curb weight by 250 pounds (although the actual curb weight hasn't been released), the new four-door can hit 60 miles per hour in a respectable eight seconds. That's not hot hatchback territory, but it should be more than suitable for the average consumer. That same consumer should also appreciate the new engine's economy. The Cruze now returns an even 40 miles per gallon on the highway and will cover 530 miles on a single tank, all the while running on plain old 87-octane fuel. There's also a diesel-powered Cruze model, although Chevy didn't release specific details, aside from saying that it will arrive in dealers in 2017, over a year after the gas-powered model's early 2016 on-sale date. Despite the 250-pound drop in weight, the new Cruze has grown significantly. Its wheelbase is now the longest in the segment, with 106.3 inches of sheetmetal between the front and rear axles compared to 105.7 in last year's model, while the sleek new body cuts the coefficient of drag to just 0.29. The overall length increases from 181 inches to 183.7, though the new model is nearly an inch lower overall. That's both good news and bad news for interior space. Rear legroom is up from 35.4 to 36.1, but headroom is down in both the front and backseats by over half an inch. Tech fans, meanwhile, will appreciate the new standard MyLink display. The seven-inch touchscreen is compatible with both Android Auto and Apple CarPlay, while an optional eight-inch display will be offered, as well. 4G LTE wi-fi, heated rear seats, a heated steering wheel, and wireless phone charging will also be offered as an optional extras. New safety features include blind-spot monitoring with cross-traffic alert, lane keeping assist, and forward collision warning.

We really want to use an eCrate to restomod an old GM car. Here's what we'd build

Fri, Oct 30 2020You hopefully saw the news today of GM's introduction of its Connect and Cruise eCrate motor and battery package, which effectively makes the Bolt's electric motor, battery pack and myriad other elements available to, ah, bolt into a different vehicle. It's the same concept as installing a gasoline-powered crate motor into a classic car, but with electricity and stuff. This, of course, got us thinking about what we'd stuff the eCrate into. Before we got too ahead of ourselves, however, we discovered that the eCrate battery pack is literally the Bolt EV pack in not only capacity but size and shape. In other words, you need to have enough space in the vehicle to place and/or stuff roughly 60% of a Chevy Bolt's length. It's not a big car, but that's still an awful lot of real estate. There's a reason GM chose to simply plop the pack into the bed and cargo area of old full-size SUVs. Well that, and having a rear suspension beefy enough to handle about 1,000 pounds of batteries. So after that buzz kill, we still wanted to peruse the GM back catalog for classics we'd love to see transformed into an electric restomod that might be able to swallow all that battery ... maybe ... possibly ... whatever, saws and blow torches exist for a reason. 1971 Buick Riviera Consumer Editor Jeremy Korzeniewski: If you’re going to build an electric conversion, why not do it with style? ThatÂ’s why IÂ’m choosing a 1971-1973 Buick Riviera. You know, the one with the big glass boat-tail rear end that ends in a pointy V. Being a rather large vehicle with a big sloping fastback shape, IÂ’m hoping thereÂ’s enough room in the trunk and back seat to pack in the requisite battery pack. That would likely require cutting away some of the metal bulkhead that supports the rear seatback, but not so much that a wee bit of structural bracing couldnÂ’t shore things up. The big 455-cubic-inch Buick V8 up front will obviously have to go. Remember, this was the 1970s, so despite all that displacement, the Riviera only had around 250 horsepower (depending on the year and the trim level). So the electric motorÂ’s 200 horsepower and 266 pound-feet of torque ought to work as an acceptable replacement.  1982 Chevrolet S10 Associate Editor Byron Hurd: OK, so the name "E-10" is already taken by a completely different truck, but let's not let labels get in the way of a fun idea.