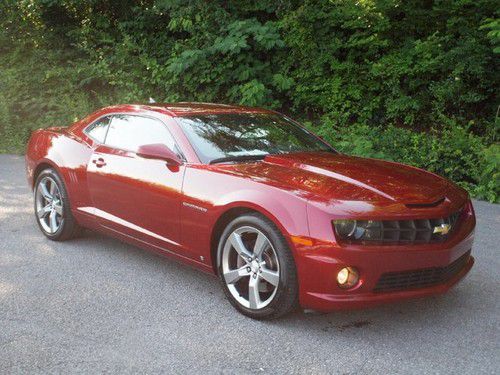

2011 Chevrolet Camaro 2ss Synergy Green Metallic on 2040-cars

Tulsa, Oklahoma, United States

Body Type:Coupe

Vehicle Title:Clear

Engine:6.2L 376Cu. In. V8 GAS OHV Naturally Aspirated

Fuel Type:GAS

For Sale By:Dealer

Number of Cylinders: 8

Make: Chevrolet

Model: Camaro

Trim: SS Coupe 2-Door

Drive Type: RWD

Mileage: 26,305

Disability Equipped: No

Sub Model: 2SS

Doors: 2

Exterior Color: Green

Drive Train: Rear Wheel Drive

Interior Color: Black

Number of Doors: 2

Chevrolet Camaro for Sale

1998 chevrolet camaro z28 ss coupe 2-door 5.7l(US $14,000.00)

1998 chevrolet camaro z28 ss coupe 2-door 5.7l(US $14,000.00) 1999 chevrolet camaro base coupe 2-door 3.8l(US $2,800.00)

1999 chevrolet camaro base coupe 2-door 3.8l(US $2,800.00) 2ss rs automatic leather v8

2ss rs automatic leather v8 Zl1 black 2012 camaro(US $57,350.00)

Zl1 black 2012 camaro(US $57,350.00) 11 chevy camaro 2ss ss 6.2l v8 6-speed manual black on black leather hud

11 chevy camaro 2ss ss 6.2l v8 6-speed manual black on black leather hud 2011 chevrolet camaro rs rwd - 6 cylinder - only 12k miles!!!(US $18,995.00)

2011 chevrolet camaro rs rwd - 6 cylinder - only 12k miles!!!(US $18,995.00)

Auto Services in Oklahoma

Triple T Motors ★★★★★

Top Tech Automotive ★★★★★

Tally`s Towing ★★★★★

Sapulpa Auto Repair ★★★★★

Reliable Motors ★★★★★

Kwik Lube ★★★★★

Auto blog

Seeing the Detroit Auto Show via drone

Sun, Jan 18 2015Seeing the Chevrolet display at the Detroit Auto Show is worth doing this year, and not just because of the new Corvette Z06, Volt and Bolt concept. In order to attract the new kids, The Bowtie has gone what the old kids used to call "buck wild" with their show stand at Cobo Hall. A Corvette Z06, Trax, and Colorado are parked along a central aisle, called Mainstreet, at the end of which is a 20-foot-tall, 73-foot long transparent screen lording over the new Volt. Elsewhere are five more 20-foot-tall screens broadcasting nine stories today's Chevrolet wants to tell about its vehicles, from performance to belief in the power of play to its 4G LTE-equipped OnStar telematics service. Then there are the social media and virtual reality safety installations, the community presentations and more. Chevrolet flew a drone through the stand to show off what it's doing, which is has replaced eye-level video as the next best thing to being there. You can check it out in the video above.

NHTSA could add 1M cars to GM recall

Wed, 13 Mar 2013

The Detroit Free Press is reporting that the National Highway Traffic Safety Administration may expand a recall campaign for faulty brake lamps. The agency is currently looking into complaints that certain 2004-2011 Chevrolet Malibu models as well as some 2007-2009 Saturn Aura sedans may have brake lights that do not illuminate when the driver presses the pedal. Alternatively, the lamps may also illuminate without input from the driver. General Motors recalled 8,000 Pontiac G6 models from the 2005 model year for the same problem, and NHTSA is currently investigating whether to add 550,000 more G6 models built between 2005 and 2009 to the list for the same issue.

In addition, investigators are currently examining 97 complaints from Malibu and Aura owners with the same trouble. If NHTSA adds those models to the recall campaign, more than one million units could be covered. GM, meanwhile, says there have been no accidents or injuries as a result of the problem.

GM will recall more than 3.3 million vehicles in China for suspension defect

Sat, Sep 29 2018BEIJING (Reuters) - General Motors' joint venture in China, Shanghai GM, will recall more than 3.3 million Buick, Chevrolet and Cadillac vehicles stating Oct. 20 because of a defect with the suspension system, China's market regulator said on Saturday. GM Shanghai said in a text message to Reuters that the suspension arm may be deformed under extreme operating conditions, but there are no known casualties related to the issue. The recall includes cars produced between 2013 and 2018, the State Administration for Market Regulation said in a statement. GM will contact those affected and repair the vehicles free of charge, it said. (Reporting by Josephine Mason and Hallie Gu; additional reporting by Yilei Sun; Editing by Shri Navaratnam and Michael Perry)Related Video: Image Credit: Qilai Shen/Bloomberg via Getty Recalls Buick Cadillac Chevrolet Safety