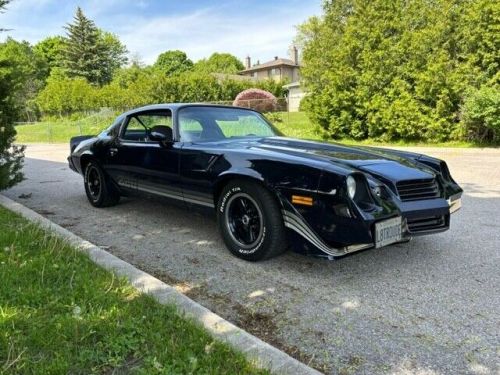

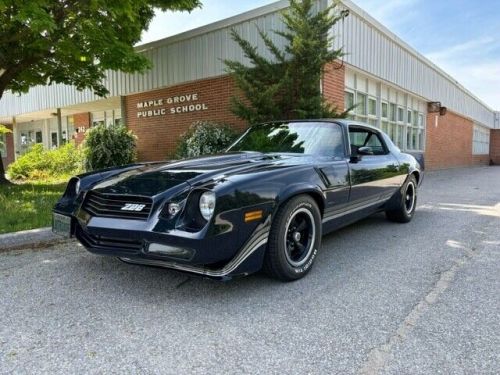

1981 Chevrolet Camaro on 2040-cars

Barrie, Ontario, Canada

Transmission:Automatic

Vehicle Title:Clean

Year: 1981

VIN (Vehicle Identification Number): 1G1AP87L6BL178228

Mileage: 52700

Interior Color: Blue

Number of Seats: 4

Model: Camaro

Exterior Color: Blue

Make: Chevrolet

Chevrolet Camaro for Sale

1969 chevrolet camaro ralley green(US $14,000.00)

1969 chevrolet camaro ralley green(US $14,000.00) 1969 chevrolet camaro x11(US $2,019.00)

1969 chevrolet camaro x11(US $2,019.00) Clean(US $20,200.00)

Clean(US $20,200.00) Clean(US $20,200.00)

Clean(US $20,200.00) 2000 chevrolet camaro z28(US $11,000.00)

2000 chevrolet camaro z28(US $11,000.00) 1997 chevrolet camaro z28(US $6,500.00)

1997 chevrolet camaro z28(US $6,500.00)

Auto blog

Recharge Wrap-up: Indianapolis to switch 425 fleet vehicles to EVs, Chevy Corvette provides bat habitats

Tue, Nov 4 2014Indianapolis will deploy 425 battery electric and plug-in hybrid vehicles as part of its municipal fleet by 2016. The fleet will include such cars as the Nissan Leaf, Chevrolet Volt and Ford Fusion Energi. The city will also reduce its overall fleet by 100 vehicles. In all, the revised group - called the "Freedom Fleet" - will save $8.7 million and 2.2 million gallons of gasoline over 10 years. Read more at Hybrid Cars. EVs with longer range would make vehicle-to-home and vehicle-to-grid energy management systems more practical for the US. The idea of using EVs as energy storage for emergencies or times of high grid demand is currently being tested in Japan with Nissan's Leaf-to-Home system. The US is also interested in such capabilities, but the higher average energy use of American households would make larger batteries in EVs ideal for grid storage applications. Read more at Green Car Reports. LG Chem has broken ground on its EV battery plant in Nanjing, China. The factory, when constructed, will have a capacity of producing batteries for 100,000 cars per year according to the Korean company. The plant will supply batteries for Chinese automakers such as SAIC and Qoros. Construction is expected to be finished by the end of 2015 and LG Chem expects revenue of more than $933 million by 2020. Read more in the press release below. General Motors is using adhesive used in the Chevrolet Corvette Stingray to create habitat for threatened bat species. Artificial bat caves could help alleviate white-nose fungus that leads to diminished bat populations. Leftover adhesive is used to create stalactites in the artificial caves, allowing them more structure to hang from. GM has also provided Volt battery covers to create nesting habitats for bats, which eat harmful insects and help pollinate plants. See the videos and read more in the press release below. This content is hosted by a third party. To view it, please update your privacy preferences. Manage Settings. This content is hosted by a third party. To view it, please update your privacy preferences. Manage Settings. LG Chem officially breaks ground for China EV battery plant Seoul, Korea - Oct 30, 2014 – LG Chem, Korea's leading manufacturer of advanced batteries, held a ground breaking ceremony for the construction of electric-car battery plant in Nanjing, China, to meet growing demand in the world's biggest car market.

Chevy SS to get 1LE-like handling pack

Tue, Feb 17 2015Chevrolet engineers have more plans for the SS, but official approval stands between their wishes and our driving commands. After getting the no-cost option for a six-speed manual last year, Motor Trend reports that some company boffins want to throw the Camaro's track-focused 1LE package at it. On the Camaro that means the Performance Ride and Handling suspension, front and rear stabilizer bars, and 20-inch wheels all around concerning the road-focused bits. MT says that a 1LE on the SS would shed the staggered tires for one size all around, and get new dampers and a new suspension tune. It wouldn't turn the SS into a Dodge Charger SRT Hellcat, but the SS could do even more with its 415 horsepower and 415 pound-feet, hopefully without sacrificing too much of its plush road comfort in the process. It's said that a production example could be done in less than six months, but it sounds like the approval process will take longer. Featured Gallery 2014 Chevrolet SS: Review View 31 Photos News Source: Motor TrendImage Credit: Copyright 2015 AOL Chevrolet Luxury Performance Sedan chevy camaro 1le 1le

Submit your questions for Autoblog Podcast #313 LIVE!

Mon, 17 Dec 2012We record Autoblog Podcast #313 tonight, and you can drop us your questions and comments regarding the rest of the week's news via our Q&A module below. Subscribe to the Autoblog Podcast in iTunes if you haven't already done so, and if you want to take it all in live, tune in to our UStream (audio only) channel at 10:00 PM Eastern tonight.

Discussion Topics for Autoblog Podcast Episode #313

2014 Chevrolet Silverado and GMC Sierra introduced