2013 Tesla Model S on 2040-cars

Clute, Texas, United States

For sale is my 2013 Tesla Model S60 with 62,394 miles. It has the rare brown metallic exterior with a tan and

piano black interior. Other options/upgrades include the following:

Battery Upgrade (60kWh)

Free Supercharging

Unlimited Internet with 3G to LTE upgrade retrofit

Tech Package with LED foglights and cornering lights, auto-dimming exterior mirrors, a power rear hatch,

keyless ignition/entry and driver memory settings

Interior Lighting Package

TPMS retrofit to show independent tire pressures

Evannex Center Console Insert in matching Piano Black and Tan

Mobile Connector Bundle with NEMA plugs 110V and 220V

Two Tesla Model S Key Fobs

Includes free supercharging. It has been upgraded from 3G to LTE connectivity as well as TPMS to show independent

tire pressures. The high voltage battery was replaced at 55,000 miles. Tires were replaced with Goodyear Eagle's

at 37,218 and 52,000 miles.

Bugatti Veyron for Sale

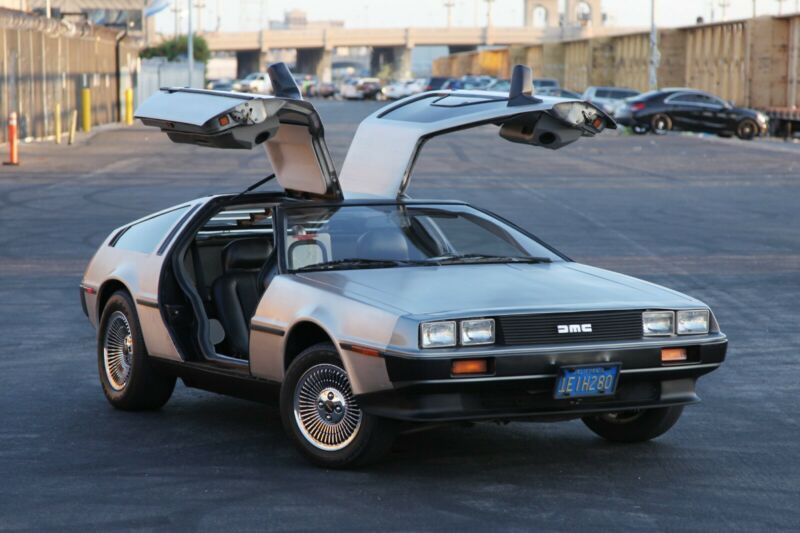

1981 delorean dmc-12(US $18,830.00)

1981 delorean dmc-12(US $18,830.00) The car(US $9,987,756,446.00)

The car(US $9,987,756,446.00) The(US $0.00)

The(US $0.00) 2012 bugatti veyron(US $90,000.00)

2012 bugatti veyron(US $90,000.00) Movers, moving company(US $55,443.00)

Movers, moving company(US $55,443.00) 1931 - bugatti royale(US $80,000.00)

1931 - bugatti royale(US $80,000.00)

Auto Services in Texas

Wolfe Automotive ★★★★★

Williams Transmissions ★★★★★

White And Company ★★★★★

West End Transmissions ★★★★★

Wallisville Auto Repair ★★★★★

VW Of Temple ★★★★★

Auto blog

Kawasaki H2R races Bugatti Veyron, MP4-12C, and 1,350-hp GT-R

Fri, May 22 2015The Kawasaki Ninja H2R ranks among the modern marvels of the production motorcycle world. The bike is only for the track, but with a 1.0-liter, supercharged, four-cylinder engine making 300 horsepower, it's ludicrously quick. Super Street decided to put that acceleration to the test by staging a half-mile race against a Bugatti Veyron with the 1,200-hp tune from the Super Sport. We aren't going to spoil the winner, but according to Super Street this bike is the only H2R that Kawasaki USA currently has. The magazine also staged similar races against a McLaren MP4-12C and a Nissan GT-R with a claimed 1,350 hp, and you can check them both out below. If you're curious to read more about this event, there's an in-depth piece online about it all, as well.

Bugatti not planning an EV or SUV in the next 10 years

Thu, Sep 8 2022Bugatti is at a turning point in its history: It will end production of the Chiron and the W16 engine that powers it in the coming years. What's next remains a little murky, but the company confirmed that it's not planning on releasing an electric car or an SUV for at least 10 years. "A purely electric version is not included in our 10-year plan for Bugatti. There will also be no SUV," said Bugatti-Rimac CEO Mate Rimac in an interview with industry trade journal Automobilwoche. "If it's comparable, then it's not a Bugatti," he added, citing the firm's founder. His comments put an end to the rumors that have hovered around Bugatti since Croatia-based Rimac purchased a controlling stake in July 2021. Rimac made a name for itself by developing high-performance EVs, and some feared it would leverage its expertise to launch a range of badge-engineered battery-powered Bugatti models. Rimac ruled out badge engineering early on and stressed the two brands won't overlap, though its CEO predicted that "within this decade there will be a fully electric Bugatti" shortly after the purchase was announced. Bugatti has started developing the Chiron's successor and Autoblog confirmed in August 2022 that the model will be powered by a plug-in hybrid drivetrain. Rimac stopped short of revealing precise technical details about the yet-unnamed model but told Automobilwoche his team hopes to increase the system's electric-only range from approximately 12 miles in some gasoline-electric hypercars to 30 miles. More details about Bugatti's future should emerge in the coming months. In the meantime, the company has its work cut out for the coming years: it needs to finish production of the Chiron, build the track-only Bolide, and make the 99 planned units of the sold-out Mistral (pictured). Related video:

Bugatti brings 5 of its most storied classic models back home

Tue, Oct 25 2022The average Bugatti buyer already has dozens of cars and likely owns one of the brandís eye-popping cars before adding another to the stable. The automaker met with one of its most storied collectors in recent years, but it wasn¬ít hoping to sell him another car. Bugatti wanted to keep and preserve his vehicles, several of which were deeply involved in its growth as a motorsport and luxury icon. The automaker succeeded and now has brought a sizable chunk of its history home.¬† Hans Matti is the Registrar of the Bugatti Club Suisse and has amassed one of the world's most impressive collections of classic Bugatti cars. His stable held a Bugatti Type 51, a Type 37A, a Type 49 Faux cabriolet, a Type 35B, and a Type 35A. The cars each feature incredible stories, including the Type 51 with its Grand Prix racing history and a Type 49 that was Jean Bugatti¬ís personal car. The vehicle is thought to be the only one in the world with the Faux Cabriolet bodywork done at the Bugatti factory. The Type 51 was a factory race car driven by Louis Chiron. Bugatti says the Type 35A carries the engine, gearbox, and rear axle from one of its Type 36 race cars, both of which were destroyed. The Type 37A dates back to 1929 and still races today. It features a supercharger on its four-cylinder engine, which gave it a 120-mph top speed. Bugatti notes that only 76 cars were supercharged. The five cars have now made their way to Bugatti, where they rest in the Chateau Saint Jean, which Ettore Bugatti purchased to entertain customers. They¬íll be kept exactly as they are, with original paint, rivets, and other components.