Toyota Tundra for Sale

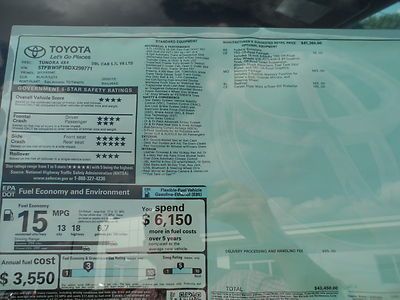

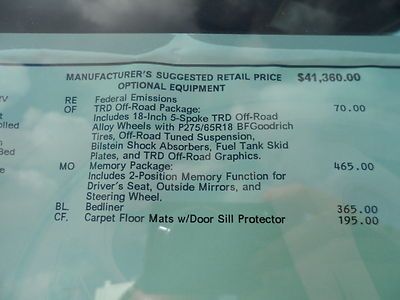

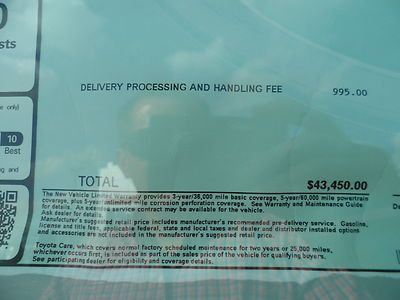

Hail sale new 2013 toyota tundra double cab 4x4 trd off-road discounted $7,689(US $32,250.00)

Hail sale new 2013 toyota tundra double cab 4x4 trd off-road discounted $7,689(US $32,250.00) Hale sale new 2013 toyota tundra double cab 4x4 trd off-road discounted $7,324(US $30,831.00)

Hale sale new 2013 toyota tundra double cab 4x4 trd off-road discounted $7,324(US $30,831.00) Hale sale new 2013 toyota tundra double cab 4x4 trd off-road discounted $7,324(US $30,831.00)

Hale sale new 2013 toyota tundra double cab 4x4 trd off-road discounted $7,324(US $30,831.00) 2004 toyota tundra sr5 extended cab pickup 4-door 4.7l(US $17,500.00)

2004 toyota tundra sr5 extended cab pickup 4-door 4.7l(US $17,500.00) 2012 toyota tundra base crew cab pickup 4-door 4.6l(US $28,988.00)

2012 toyota tundra base crew cab pickup 4-door 4.6l(US $28,988.00) 11 limited 4x4 5.7 crewmax trd off road navi heated leather boards jbl certified(US $42,990.00)

11 limited 4x4 5.7 crewmax trd off road navi heated leather boards jbl certified(US $42,990.00)

Auto blog

Toyota turning landfill gas into hybrid vehicles, indirectly

Fri, Mar 28 2014Chamillionaire certainly wasn't referring to the Toyota Avalon or Camry when he rapped about "ridin' dirty" but maybe he'll change his tune soon. That's because some of the future energy sources for the Kentucky factory that makes those two models will come from gas created from the breakdown of solid waste. So the power behind some of the production at Toyota's largest North American factory will indeed be funky. Toyota is working with Waste Services of the Bluegrass to build a network of wells at a nearby landfill in order to collect the gases. Construction of the system starts next month and will be finished by early next year. The upshot is that the system will produce one megawatt of electricity per hour, which is the equivalent to the power used by 800 houses. Last spring, Toyota said it would start producing the Lexus ES at the Kentucky plant after getting almost a $150 million offer from the state. That's because that model is expected to add 50,000 vehicles to the existing production numbers at the plant. And those production numbers are already large, as Toyota makes both the standard and hybrid versions of both the Camry and Avalon there. Mind you, Toyota's not the first to go this route for factory-energy production. In 2011, General Motors' Orion Assembly Plant started getting about 40 percent of its energy for production of models such as the Chevy Sonic and Buick Verano from methane captured from a landfill nearby. The General estimated at the time that the process would cut the company's energy costs by about $1.1 million a year. Check out Toyota's press release about the Kentucky plant and its future landfill gas below. Landfill Gas to Build Cars and a Greener Community Partnership between Toyota and local landfill turns garbage into good March 24, 2014 GEORGETOWN, Ky. (MARCH, 24 2014) – Can a car company be a vehicle for change? Toyota thinks so. The Kentucky plant that manufactures some of the greenest cars on the road, including two hybrid models, will soon be powered in part by green electricity. Toyota Motor Manufacturing, Kentucky, Inc. has teamed up with Waste Services of the Bluegrass to generate power from local landfill waste, marking the region's first business to business landfill gas to energy initiative. Toyota estimates the locally-generated landfill gas will supply enough power each year for the production of 10,000 vehicles. How it Works As solid waste naturally breaks down in a landfill, it creates gas.

Toyota's new TNGA platform could boost Prius to 58 mpg

Sun, Mar 29 2015First, let's put the necessary context around the phrase, "Toyota New Global Architecture platform." The platform is important, but it is just one flowering bud sprouting from the real action, which is the production processes that will create it. It is crucial to understand that TNGA is fundamentally about a revolution in how Toyota designs and builds its cars - it even includes an overhaul of management and human resources - with one of the benefits being the new platform that the 2016 Prius will ride on. The Daily Kanban goes in depth about the changes, but integrated development for powertrain and platforms serves to reduces costs through more parts-sharing at the same time as it creates more cohesive platforms that are lighter, more compact, and have more efficient layouts. Regarding hybrids, Toyota says the new drive unit layout along with small components could raise hybrid efficiency "by more than 15 percent." That might enable the 2016 Prius to return 57.5-mpg combined - almost 59 in the city, 55 on the highway. Plus, the higher rigidity, lower center of gravity, and better suspension of the new platform will provide a better driving experience. All of these changes will be reflected in platforms for large and rear-wheel-drive vehicles, too. It is factory and build-process refinement that allows the development advances to be fully exploited. Toyota is making its lines more flexible, partly by having actual assembly lines that can easily be shortened, lengthened, or trucked somewhere else, and partly by introducing machines that can build parts for many different vehicles on the same line as needed, without using molds. The flexibility extends to capital investment, too, with much less money needed in order to switch to a new product build. Toyota says it is doing this to "improve core vehicle performance and product appeal," the overhaul making it simpler to produce new designs and features. Factory workers benefit from the flexibility as well; being able to build more types of cars means they aren't hamstrung by the sales fortunes of a small number of models. You'll find plenty of specifics in the press release below. Making Ever-better Cars: A Progress Report "Sudden and drastic changes in the business environment mean that conventional ways of thinking and doing business can no longer help us grow sustainably.

2014 Toyota 4Runner Limited

Thu, 08 May 2014What would you say if we told you that outside of Jeep and Land Rover, the best brand for those who want to go off road is Toyota? Sounds remarkable, eh? But the truth is, Toyota's history of providing vehicles for the rougher bits of our blue marble dates back to 1950, barely a decade after Willys built the first Jeeps and only a few years after Land Rover made its big debut with the iconic Series I.

In fact, Toyota's start in off-roaders was with a small contract for providing the US Army with vehicles, during the Korean War. From that, the BJ was spawned. This Jeep-like vehicle evolved into the 20 Series and then into the iconic 40 Series Land Cruiser in the 1960s.

So yes, Toyota knows its way around the trails. While the Land Cruiser, deservedly, gets all the attention thanks to its impressive longevity, we're partial to the 4Runner, which is a far more affordable entry that serves as Toyota's challenger to the Jeep Grand Cherokee.