Trd Off Road~crew Cab~super Deal~one-owner~excellent Condition~dealer Maintained on 2040-cars

Sterling, Virginia, United States

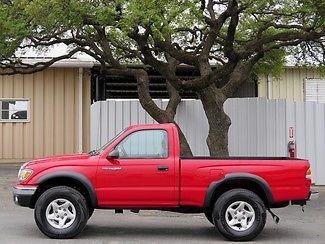

Toyota Tacoma for Sale

2001 toyota tacoma double cab trd off road 4x4

2001 toyota tacoma double cab trd off road 4x4 2wd dbl v6 at prerunner 4 dr crew cab truck automatic gasoline 4.0l v6 fi dohc 2

2wd dbl v6 at prerunner 4 dr crew cab truck automatic gasoline 4.0l v6 fi dohc 2 4 cylinder cruise clean pioneer radio regular cab spray in bed liner we finance(US $7,981.00)

4 cylinder cruise clean pioneer radio regular cab spray in bed liner we finance(US $7,981.00) Tacoma prerunner double cab 4x2 v6 3tmju62n49m071250

Tacoma prerunner double cab 4x2 v6 3tmju62n49m071250 Excelentes condiciones, rines 18" color rojo, 111400 millas.(US $14,500.00)

Excelentes condiciones, rines 18" color rojo, 111400 millas.(US $14,500.00) Sr5 double cab v6 prerunner reverse camera 16" alloys tow automatic warranty aux(US $24,988.00)

Sr5 double cab v6 prerunner reverse camera 16" alloys tow automatic warranty aux(US $24,988.00)

Auto Services in Virginia

Z Auto Body ★★★★★

Wooddale Automotive Specialist ★★★★★

White Tire Distributors ★★★★★

Vega MotorSport Window Tinting & Detailing ★★★★★

Tysinger Motor Co., Inc. ★★★★★

The Body Works of VA INC ★★★★★

Auto blog

Tougher than steel: Wood pulp could make lighter auto parts

Tue, Aug 15 2017KYOTO, Japan — The global push among carmakers to make ever lighter vehicles is leading some auto suppliers in Japan to turn to what seems like an unlikely steel substitute — wood pulp. Japanese researchers and auto component makers say a material made from wood pulp weighs just one-fifth of steel and can be five times stronger. The material - cellulose nanofibers — could become a viable alternative to steel in the decades ahead, they say, although it faces competition from carbon-based materials, and remains a long way from being commercially viable.> Related: Jay Leno drives the Renew cannabis car — hemp you can't dent Reducing the weight of a vehicle will be critical as manufacturers move to bring electric cars into the mainstream. Batteries are an expensive but vital component, so a reduction in car weight will mean fewer batteries will be needed to power the vehicle, saving on costs. "Lightweighting is a constant issue for us," said Masanori Matsushiro, a project manager overseeing body design at Toyota. "But we also have to resolve the issue of high manufacturing costs before we see an increased use of new, lighter-weight materials in mass-volume cars."A NEW PROCESS Researchers at Kyoto University and major parts suppliers such as Denso Corp, Toyota's biggest supplier, and DaikyoNishikawa Corp, are working with plastics incorporated with cellulose nanofibers — made by breaking down wood pulp fibers into several hundredths of a micron (one thousandth of a millimeter). Cellulose nanofibers have been used in a variety of products ranging from ink to transparent displays, but their potential use in cars has been enabled by the "Kyoto Process," under which chemically treated wood fibers are kneaded into plastics while simultaneously being broken down into nanofibers, slashing the cost of production to roughly one-fifth that of other processes. "This is the lowest-cost, highest-performance application for cellulose nanofibers, and that's why we're focusing on its use in auto and aircraft parts," Kyoto University Professor Hiroaki Yano, who is leading the research, told Reuters in an interview. The university, along with auto parts suppliers, are currently developing a prototype car using cellulose nanofiber-based parts to be completed in 2020.

Ford Fusion production scaled back just 3 months after it was accelerated

Mon, 02 Dec 2013Three months after kicking off production of the Ford Fusion at its Flat Rock, MI factory, Ford Motor Company is taking steps to trim output in the face of heavily discounted competition from Toyota and a growing supply of vehicles.

The addition of Fusion production in Flat Rock - which also builds the Mustang - was meant to be what pushed the handsome mid-sizer past its arch-nemesis, the Toyota Camry. An extra facility building Fusions was also meant to curb the growing demand for Ford's highly profitable sedan.

But with word that Flat Rock would take "approximately" one extra week off for the holidays combined with an 88-day supply of Fusions - reportedly due in no small part to what Morgan Stanley analyst Adam Jonas called "aggressive discounting of the Camry" - some analysts are now beginning to wonder if Ford may have overextended itself by adding a second Fusion facility to the mix.

Toyota To Stop Building Cars In Australia

Tue, Feb 11 2014Toyota said Monday it will stop making cars in Australia by the end of 2017, spelling a final blow to auto manufacturing in the country, where car companies say high production costs and tough competition have crippled business conditions. Toyota's announcement, which will result in the loss of around 2,500 jobs, was widely anticipated, coming just two months after General Motors Co. said it would end production in Australia by 2017. Ford Motor Co. announced in May that it would cease Australian production in 2016. All told, some 6,600 manufacturing jobs will be lost between the three companies. Mitsubishi Motors Corp. stopped manufacturing in Australia in 2008. Toyota Motor Corp. said its decision was based on a combination of factors including the high Australian dollar, the high cost of manufacturing and competition. "We did everything that we could to transform our business," Toyota Australia CEO Max Yasuda said in a statement. "But the reality is that there are too many factors beyond our control that make it unviable to build cars in Australia." Toyota President Akio Toyoda delivered the news to workers at the company's Altona plant near Melbourne, where he paid tribute to 50 years of Toyota cars being built in Australia. "To now have to deliver this news to the very people we have worked so hard with, to the many people who have supported our production for so many years, is most regretful for Toyota and, for me personally, simply heartbreaking," he said. Toyota, which has been manufacturing cars in Australia since 1963, currently makes the Camry, Camry Hybrid and Aurion in the country. It will become a sales company. Industry Minister Ian Macfarlane said Toyota had not asked the government for any financial assistance in the lead-up to its decision. The government had subsidized auto manufacturing, hoping to keep the industry alive as it supports tens of thousands of jobs in other areas including auto parts. Holden, which is the Australian arm of GM, received 1.8 billion Australian dollars ($1.6 billion) in federal government assistance in the past 11 years. Auto makers in Australia produced about 178,000 cars in 2012, according to the International Organization of Motor Vehicle Manufacturers. Related Gallery AOL Autos Test Drive: 2014 Toyota Highlander Plants/Manufacturing Toyota