Base 4.0l Vanity Mirrors Side Impact Door Beams Vehicle Stability Assist Clock on 2040-cars

Toledo, Ohio, United States

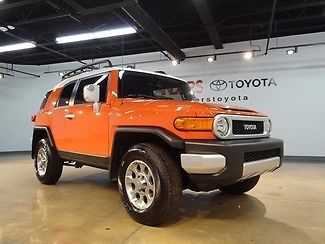

Toyota FJ Cruiser for Sale

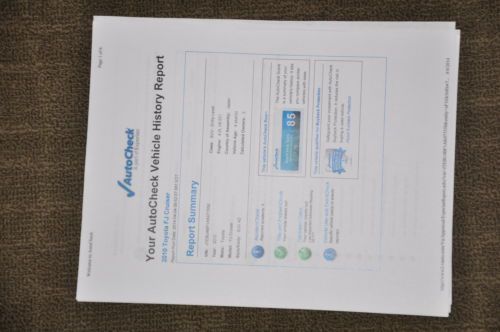

2007 toyota fj cruiser base sport utility 4-door automatic-rebilt title $12,500

2007 toyota fj cruiser base sport utility 4-door automatic-rebilt title $12,500 2008 toyota fj cruiser trail teams 4wd(US $23,980.00)

2008 toyota fj cruiser trail teams 4wd(US $23,980.00) 2008 toyota fj cruiser 4x4 automatic roof rack tow 68k texas direct auto(US $20,780.00)

2008 toyota fj cruiser 4x4 automatic roof rack tow 68k texas direct auto(US $20,780.00) 1977 classic toyota land cruiser special edition

1977 classic toyota land cruiser special edition Suv 4.0l cd 4x4 locking/limited slip differential, one owner, non smoker

Suv 4.0l cd 4x4 locking/limited slip differential, one owner, non smoker 2013 toyota fj cruiser 4wd automatic suv 5-speed automatic(US $31,609.00)

2013 toyota fj cruiser 4wd automatic suv 5-speed automatic(US $31,609.00)

Auto Services in Ohio

Zig`s Auto Service ★★★★★

Zeppetella Auto Service ★★★★★

Willis Automobile Service ★★★★★

Voss Collision Centre ★★★★★

Updated Automotive ★★★★★

Tri C Motors ★★★★★

Auto blog

Asian automakers still reluctant to use more aluminum

Tue, Jun 24 2014There's a logical progression of technology in the auto industry. We've seen it with things like carbon-ceramic brakes, which use to be the sole domain of six-figure sports cars, where they often cost as much as an entry level Toyota Corolla. Now, you can get them on a BMW M3 (they're still pricey, at $8,150). Who knows, maybe in the next four a five years, they'll be available on something like a muscle car or hot hatchback. Aluminum has had a similar progression, although it's further along, moving from the realm of Audi and Jaguar luxury sedans to Ford's most important product, the F-150. With the stuff set to arrive in such a big way on the market, we should logically expect an all-aluminum Toyota Camry or Honda Accord soon, right? Um, wrong. Reuters has a great report on what's keeping Asian manufacturers away from aluminum, and it demonstrates yet another stark philosophical difference between automakers in the east and those in the west. Of course, there's a pricing argument at play. But it's more than just the cost of aluminum sheet (shown above) versus steel. Manufacturing an aluminum car requires extensive retooling of existing factories, not to mention new relationships with suppliers and other logistical and financial nightmares. Factor that in with what Reuters calls Asian automaker's preference towards "evolutionary upgrades," and the case for an all-aluminum Accord is a difficult one. Instead, manufacturers in the east are focusing on developing even stronger steel as a means of trimming fat, although analysts question how long that practice can continue. Jeff Wang, the automotive sales director for aluminum supplier Novelis, predicts that we'll see a bump in aluminum usage from Japanese and Korean brands in the next two to three years, and that it will be driven by an influx of aluminum-based vehicles from western automakers into China. Only time will tell if he's proven right. News Source: ReutersImage Credit: Sean Gallup / Getty Images Plants/Manufacturing Honda Hyundai Mazda Nissan Toyota Technology aluminum

Recharge Wrap-up: Mazda, Toyota earn environmental awards

Tue, Nov 10 2015Electric mobility nonprofit Drive Oregon has launched a campaign to invite the electric car industry to perform testing in the state. The campaign tells companies to, "Test Drive the Future in the Living Lab," citing Oregon's density of EV owners and charging infrastructure, varied terrain and climate, funding opportunities, and the state's technological reputation as the "Silicon Forest." Plus, as Drive Oregon Executive Director Jeff Allen, points out, "if you really screw things up here, it doesn't make as much noise as it would in California." Already, Jaguar Land Rover has announced plans for an Innovation Incubator in Oregon. Read more at Green Car Reports. Mazda's new paint system has won the Prime Minister's Award in the category of Manufacturing and Production Process at the 6th Monodzukuri Nippon Grand Award ceremony. Mazda's Aqua-tech paint system significantly reduces emissions of volatile organic compounds (VOCs) and CO2. The Aqua-tech system uses a water-based color basecoat and a urethane clear coat to reduce VOC emissions by 57 percent. It consolidates the painting process and reduces energy in paint-booth air-conditioning and flash-off processes to reduce energy consumption. It also allows Mazda to create such colors as Soul Red, which looks quite nice on the MX-5 Miata. Read more at Green Car Congress, and learn all about the Aqua-tech paint process from Mazda. The Toyota Mirai has received a 2015 Environmental Award from Austrian automobile club ARBO. The hydrogen fuel cell car took the prize in the category of Current Innovative Environmental Technologies. "At Toyota, we believe that various technologies will co-exist, ranging from EVs to hybrids to the most innovative of all, the fuel cell car," says Gerald Killmann, Vice President R&D of Toyota Motor Europe, in a comment thanking ARBO. "Mirai is a core component of Toyota's vision for a sustainable mobility society, one that allows us all to move freely in comfort and safety in an environmentally friendly, sustainable manner." Read more in the press release below. Vienna, Austria- November 5th - The Austrian automobile club ARBO* (Auto-Motor und Radfahrerverbund Osterreiche) has awarded the Toyota Mirai with the "2015 Environmental Award". This Award was received during a gala ceremony held yesterday in Vienna, where the Toyota Mirai was awarded in the category of "Current Innovative Environmental Technologies" . The jury consisted of ARBO automotive experts.

Australia may offer money to keep Toyota making cars there

Tue, 04 Jun 2013In the wake of last month's announcement that Ford will cease automotive and engine production in Australia after 2016, many are wondering what the country's other automakers will do. Holden has already confirmed it will stay the course despite Ford's exit.

Much of the GM subsidiary's reason for sticking around has to do with a deal made last year between Holden and the Australian government. In order to secure a GM investment of $1 billion and a commitment to keep manufacturing in Australia through 2022, the government threw in an extra $215 million. According to Australia's Minister for Innovation and Industry, Greg Combet, the government is now in talks with Toyota for a similar deal.

Toyota operates one plant in Australia, the Altona manufacturing and engine plant in Victoria. The facility produces the Camry, Camry Hybrid and Australasia-only Aurion for both the local market and export. The report from GoAuto indicates that negotiations with the Australian government would include adding production of a third, all-new model at Altona, possibly the new RAV4, because it shares many parts with the Camry.