2014 Toyota Avalon Limited on 2040-cars

10011 Spencer Rd, Saint Peters, Missouri, United States

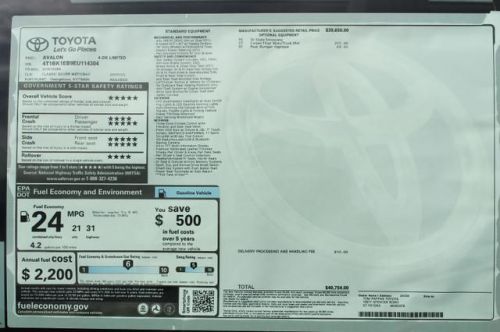

Engine:3.5L V6 24V MPFI DOHC

Transmission:6-Speed Automatic

VIN (Vehicle Identification Number): 4T1BK1EB9EU114304

Stock Num: T22670

Make: Toyota

Model: Avalon Limited

Year: 2014

Exterior Color: Classic Silver Metallic

Interior Color: Light Gray

Options: Drive Type: FWD

Number of Doors: 4 Doors

Mileage: 1

Now offering 10 Year 100,000 Miles power train Warranty. Please print this page and bring to me, Matthew Howat when you visit our dealership. Experience the Pappas Toyota difference; we have been in business in St. Charles for over 30 years! Contact our internet department at 888-426-1199 Toll Free and we would be happy to assist you!

Toyota Avalon for Sale

2014 toyota avalon xle premium(US $33,599.00)

2014 toyota avalon xle premium(US $33,599.00) 2014 toyota avalon limited(US $38,754.00)

2014 toyota avalon limited(US $38,754.00) 2014 toyota avalon hybrid limited(US $42,454.00)

2014 toyota avalon hybrid limited(US $42,454.00) 2014 toyota avalon xle premium(US $33,530.00)

2014 toyota avalon xle premium(US $33,530.00) 2014 toyota avalon limited(US $38,685.00)

2014 toyota avalon limited(US $38,685.00) 2014 toyota avalon limited(US $38,754.00)

2014 toyota avalon limited(US $38,754.00)

Auto Services in Missouri

Westport Service Center ★★★★★

Sterling Ave Auto Service ★★★★★

Santa Fe Glass Co Inc ★★★★★

Osage Auto Body ★★★★★

North West Auto Body & Service ★★★★★

Napa Auto Parts - Horn`S Auto Supply ★★★★★

Auto blog

Toyota, Nissan, Honda will work together on hydrogen filling stations

Thu, Feb 12 2015Japan's own version of the Big Three is taking on a transportation effort that's a far cry from the large-engined history of General Motors, Ford and Chrysler. In fact, Toyota, Nissan and Honda are looking to do their part – and maybe a little more – for the environment by working together to collaborate on accelerating the deployment of hydrogen fuel delivery in Japan. More refueling stations means more convenience for prospective hydrogen fuel-cell vehicle owners. Toyota says the specifics, including investment amount and the number of stations to be deployed, will be "determined at a later date." Still, the effort dovetails with that of the Japanese government. That government announced a so-called Strategic Road Map for Hydrogen and Fuel Cells last June and subsequently said it would start offering about $20,000 worth of incentives for fuel cell vehicle buyers. In December, Toyota started selling its first mass-produced fuel cell vehicle, the Mirai, in Japan and said it would almost triple production to 2,000 vehicles in 2016 from 700 this year. Last month, the Tokyo government began talks with Toyota and Honda to collaborate on ensuring that there'd be at least 6,000 fuel-cell vehicles on Japan's roads in time for the 2020 Summer Olympics in Tokyo. Tokyo officials are looking to have 100,000 fuel-cell vehicles on the city's roads by 2025. Check out Toyota's press release below. Toyota, Nissan, and Honda to Jointly Support Hydrogen Station Infrastructure Development Toyota Motor Corporation, Nissan Motor Co., Ltd., and Honda Motor Co., Ltd. have agreed to work together to help accelerate the development of hydrogen station infrastructure for fuel cell vehicles (FCVs). Specific measures to be undertaken by the three manufacturers will be determined at a later date. For hydrogen-fueled FCVs to gain popularity, it is not only important that attractive products be launched-hydrogen station infrastructure must also be developed. At present, infrastructure companies are making every effort to build such an infrastructure, but they face difficulties in installing and operating hydrogen stations while FCVs are not common on the road. Following the formulation of its Strategic Road Map for Hydrogen and Fuel Cells in June 2014, the Japanese government has highlighted the importance of developing hydrogen station infrastructure as quickly as possible in order to popularize FCVs.

Subaru to stop building Camry for Toyota in the US

Fri, 09 May 2014It was back in 2007 that Subaru of Indiana Automotive, under contract from Subaru minority shareholder Toyota, built the first Toyota Camry at its plant in Lafayette, Indiana. Rumblings of the end of that contract work have been around for a while, as Subaru talked of expanding capacity to build more units and add a line for the Impreza, and Toyota talked of moving Camry production to its Georgetown, KY plant. The news was official internally last November when SIA Executive Vice President Tom Easterday told the Louisville Courier-Journal that Camry production would end. Now, Automotive News reports that both automakers have admitted publicly that the end will come in 2016.

SIA currently has a 170,000-unit capacity devoted to the home-brand Legacy and Outback models, while a $400-million expansion increases that to 300,000 units to prepare the facility for Impreza production in two years. Freeing up the 100,000 units of production devoted to the Camry means a 400,000-unit capability, which is far more than Subaru needs at the moment, but the Toyota exit will allow it to expand any way it sees fit. Subaru has said it will absorb the workers on the Camry line and no jobs will be lost, the mayor of Lafayette saying the development could change the timetable for the expansion.

Tougher than steel: Wood pulp could make lighter auto parts

Tue, Aug 15 2017KYOTO, Japan — The global push among carmakers to make ever lighter vehicles is leading some auto suppliers in Japan to turn to what seems like an unlikely steel substitute — wood pulp. Japanese researchers and auto component makers say a material made from wood pulp weighs just one-fifth of steel and can be five times stronger. The material - cellulose nanofibers — could become a viable alternative to steel in the decades ahead, they say, although it faces competition from carbon-based materials, and remains a long way from being commercially viable.> Related: Jay Leno drives the Renew cannabis car — hemp you can't dent Reducing the weight of a vehicle will be critical as manufacturers move to bring electric cars into the mainstream. Batteries are an expensive but vital component, so a reduction in car weight will mean fewer batteries will be needed to power the vehicle, saving on costs. "Lightweighting is a constant issue for us," said Masanori Matsushiro, a project manager overseeing body design at Toyota. "But we also have to resolve the issue of high manufacturing costs before we see an increased use of new, lighter-weight materials in mass-volume cars."A NEW PROCESS Researchers at Kyoto University and major parts suppliers such as Denso Corp, Toyota's biggest supplier, and DaikyoNishikawa Corp, are working with plastics incorporated with cellulose nanofibers — made by breaking down wood pulp fibers into several hundredths of a micron (one thousandth of a millimeter). Cellulose nanofibers have been used in a variety of products ranging from ink to transparent displays, but their potential use in cars has been enabled by the "Kyoto Process," under which chemically treated wood fibers are kneaded into plastics while simultaneously being broken down into nanofibers, slashing the cost of production to roughly one-fifth that of other processes. "This is the lowest-cost, highest-performance application for cellulose nanofibers, and that's why we're focusing on its use in auto and aircraft parts," Kyoto University Professor Hiroaki Yano, who is leading the research, told Reuters in an interview. The university, along with auto parts suppliers, are currently developing a prototype car using cellulose nanofiber-based parts to be completed in 2020.