Auto Services in California

Auto Repair & Service, New Car Dealers, Brake Repair

Address: 2233 Corinth Ave, Universal-City

Phone: (310) 914-1601

Auto Repair & Service, Automobile Parts & Supplies, Auto Transmission

Address: 13903 Marquardt Ave, Compton

Phone: (562) 802-1332

Auto Repair & Service

Address: 14834 Valley Blvd, Bell

Phone: (626) 820-0267

New Car Dealers, Automobile Leasing

Address: 701 E Colorado St, South-El-Monte

Phone: (818) 500-9933

Auto Repair & Service, New Car Dealers, Brake Repair

Address: 55 Oak St, Brisbane

Phone: (415) 626-6936

Auto Repair & Service, Automobile Parts & Supplies, Auto Engine Rebuilding

Address: 566 E St, Imperial

Phone: (760) 344-3370

Auto blog

Tue, Jun 27 2017

Chipmaker Nvidia Corp announced on Monday it was partnering with Volvo Cars and Swedish auto supplier Autoliv to develop self-driving car technology for vehicles due to hit the market by 2021. Volvo is owned by China's Geely Automobile Holdings. Silicon Valley-based Nvidia also announced a non-exclusive partnership with German automotive suppliers ZF and Hella for artificial intelligence technology for autonomous driving. Nvidia came to prominence in the gaming industry for designing graphics processing chips, but in recent years has been a key player in the automotive sector for providing the so-called "brain" of the autonomous vehicle. The company, whose many partners already include Tesla, Toyota, Ford, Audi, BMW, and tier one supplier Robert Bosch, announced its latest deals at an automotive electronics show in Ludwigsburg, Germany. Nvidia's Drive PX artificial intelligence platform is used by Tesla in its Models S and X and upcoming Model 3 electric vehicles. Volkswagen AG's Audi is also using the system to reach full autonomous driving by 2020. In a call with reporters, Nvidia's senior automotive director Danny Shapiro said carmakers and their main suppliers are now moving away from the research and development phase of autonomous vehicles and into concrete production plans. The system developed jointly by ZF and Hella, and using Nvidia's Drive PX platform, will combine front cameras with radar and software to create technology meeting the Euro NCAP safety certification for so-called "Level 3" driving, in which some, but not all, driving is performed by the car. Volvo is already using the Drive PX for the self-driving cars in its "Drive Me" autonomous pilot program. Volvo's production vehicles built on Nvidia's platform, as announced on Monday, are planned for sale by 2021.Reporting By Alexandria SageRelated Video: Auto News Green Tesla Toyota Volvo Technology Emerging Technologies Autonomous Vehicles nvidia autoliv

Tue, 29 Apr 2014

Toyota's surprising announcement on Monday that it will move its North American headquarters from Torrance, CA location to the Dallas suburb of Plano, TX is allegedly not due to any political wrangling from the state's Republican governor, Rick Perry.

Perry (above) has been up front in his aggressive pursuit of businesses and jobs for Texas, traveling to California, Missouri, Illinois and New York to tempt corporations to his state. And it's not just about the promise of much lower taxes, a Perry spokesman reminds Automotive News that the state boasts, "a workforce that is skilled and ready to do any job."

For his part, Jim Lentz, Toyota's North American CEO said Plano was chosen through an internal process, with the location helped by its proximity to the company's massive pickup factory in San Antonio rather than any campaigning from the governor.

Fri, Mar 28 2014

Chamillionaire certainly wasn't referring to the Toyota Avalon or Camry when he rapped about "ridin' dirty" but maybe he'll change his tune soon. That's because some of the future energy sources for the Kentucky factory that makes those two models will come from gas created from the breakdown of solid waste. So the power behind some of the production at Toyota's largest North American factory will indeed be funky. Toyota is working with Waste Services of the Bluegrass to build a network of wells at a nearby landfill in order to collect the gases. Construction of the system starts next month and will be finished by early next year. The upshot is that the system will produce one megawatt of electricity per hour, which is the equivalent to the power used by 800 houses. Last spring, Toyota said it would start producing the Lexus ES at the Kentucky plant after getting almost a $150 million offer from the state. That's because that model is expected to add 50,000 vehicles to the existing production numbers at the plant. And those production numbers are already large, as Toyota makes both the standard and hybrid versions of both the Camry and Avalon there. Mind you, Toyota's not the first to go this route for factory-energy production. In 2011, General Motors' Orion Assembly Plant started getting about 40 percent of its energy for production of models such as the Chevy Sonic and Buick Verano from methane captured from a landfill nearby. The General estimated at the time that the process would cut the company's energy costs by about $1.1 million a year. Check out Toyota's press release about the Kentucky plant and its future landfill gas below. Landfill Gas to Build Cars and a Greener Community Partnership between Toyota and local landfill turns garbage into good March 24, 2014 GEORGETOWN, Ky. (MARCH, 24 2014) – Can a car company be a vehicle for change? Toyota thinks so. The Kentucky plant that manufactures some of the greenest cars on the road, including two hybrid models, will soon be powered in part by green electricity. Toyota Motor Manufacturing, Kentucky, Inc. has teamed up with Waste Services of the Bluegrass to generate power from local landfill waste, marking the region's first business to business landfill gas to energy initiative. Toyota estimates the locally-generated landfill gas will supply enough power each year for the production of 10,000 vehicles. How it Works As solid waste naturally breaks down in a landfill, it creates gas.

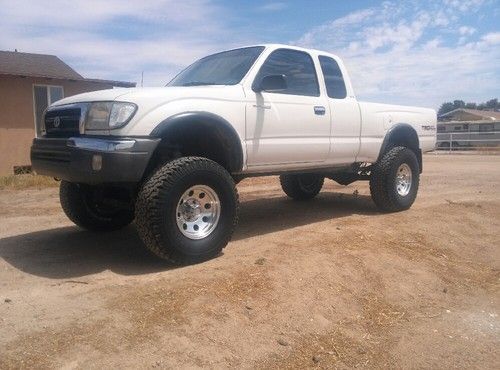

Lifted 1999 toyota tacoma prerunner extended cab pickup 2-door 3.4l sts turbo

Lifted 1999 toyota tacoma prerunner extended cab pickup 2-door 3.4l sts turbo 2009 4wd double v6 at (natl) used 4l v6 24v automatic 4wd

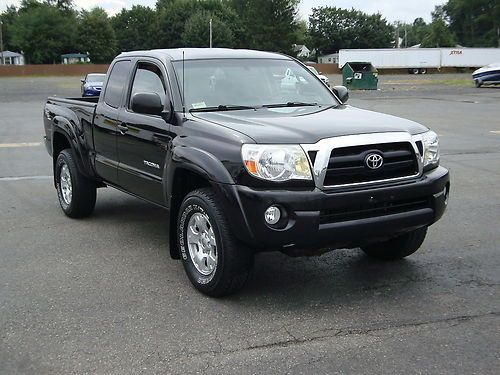

2009 4wd double v6 at (natl) used 4l v6 24v automatic 4wd 2010 toyota tacoma sr5 v6 four wheel drive 6 cylinder four door very clean

2010 toyota tacoma sr5 v6 four wheel drive 6 cylinder four door very clean 2011 toyota tacoma 4wd we finance lift kit 5 speed must see 20k mi clean car fax

2011 toyota tacoma 4wd we finance lift kit 5 speed must see 20k mi clean car fax 2006 toyota tacoma base extended cab pickup 4-door 2.7l

2006 toyota tacoma base extended cab pickup 4-door 2.7l 2006 prerunner v6 used 4l v6 24v automatic rwd

2006 prerunner v6 used 4l v6 24v automatic rwd