Toyota Celica for Sale

Auto blog

Toyota will bring Lexus-based Platform 3.0 autonomous vehicle to CES

Thu, Jan 4 2018The Toyota Research Institute says it will bring its next-generation Platform 3.0 automated driving vehicle to CES next week, an autonomous test car that is notable for incorporating the sensors and cameras into the body, rather than as ungainly attachments, and with the spinning LIDAR rooftop sensor replaced by a more sleek panel of sensors. Platform 3.0 is built on a Lexus LS600hL. Toyota Research Institute says it enlisted CALTY Design Research in Ann Arbor, Mich. and engineers at Toyota's nearby North America R&D center to conceal the equipment. As a result, Platform 3.0 gets a new rooftop weather and temperature proof panel, which it says was inspired by off-road motorcycle helmets, integrated into the available space in the sunroof compartment to minimize height. It's also embellished with chrome trim along the side, where it meets the roofline, and the rear swoops down to integrate with the LS's contour lines. The team also managed to consolidate computational electronics and wiring into a small box in the trunk. Toyota says the Platform 3.0 is one of the most perceptive autonomous test vehicles on the road today, with a design makes the test vehicle easy to build at scale. It gets a Luminar LIDAR system boasting a 200-meter, 360-degree range (the previous version only tracked the forward direction), enabled by four high-res LIDAR scanning heads that help it better see dark objects. Shorter-range LIDAR sensors feature low on all four sides of the vehicle, one on each front quarter panel and on the front and rear bumpers, to detect low-level and smaller objects, like children or road debris. Production begins this spring at the Toyota Motor North America R&D headquarters at low volumes to allow for flexibility, given the rapid rate of development of Toyota's autonomous test platforms. Some will be assembled using Toyota's Guardian dual-cockpit control layout to allow for transferring control between a human test driver and the automated system while keeping the driver as a backup, while the single-cockpit, fully autonomous Chauffeur mode will be shown at CES starting Jan. 9.Related Video: This content is hosted by a third party. To view it, please update your privacy preferences. Manage Settings. Least favorite vehicles of 2017

Toyota, Daimler Truck, Hino and Mitsubishi Fuso join forces

Tue, May 30 2023TOKYO — German truck maker Daimler, JapanÂ’s top automaker Toyota and two other automakers said Tuesday they will work together on new technologies, including using hydrogen fuel, to help fight climate change. The companies said Mitsubishi Fuso Truck and Bus Corp., whose top stakeholder is Daimler Truck, and Hino Motors, the truck maker in the Toyota group, will merge. Daimler Truck and Toyota Motor Corp. will equally invest in the holding company of the Mitsubishi-Hino merger, they said without giving a dollar amount for the deal. The companies plan to cooperate in reducing carbon emissions and developing other technologies such as autonomous driving, net-connected services and electric vehicles. “This collaboration among our four companies is a partnership for creating the future of commercial vehicles in Japan and the future of a ‘mobility society,Â’ said Toyota Motor Corp. Chief Executive Koji Sato. The two truck companies will work on commercial vehicle development, procurement and production to become globally competitive, the executives said. “We at Daimler Truck are very proud of our products, because trucks and buses keep the world moving. And soon they will even do so with zero emissions,” said Daimler Truck Chief Executive Martin Daum. “TodayÂ’s announcement is a crucial step in making that future work economically and in leading sustainable transportation.” Automakers are rushing to keep up with the global shift toward less polluting vehicles and to help in other ways to combat climate change. Commercial vehicles like trucks and buses are major contributors to auto emissions. In some cases rivals are joining forces to gain a a competitive edge and cut costs through “economies of scale” of by sharing knowledge and resources. “It is hard to go at it alone. Working together is crucial,” Sato said, Fuel cells power ToyotaÂ’s buses in Japan but its strength has been in hybrids, which have both electric motors like EVs and gasoline engines. Consumer acceptance of battery powered EVs has come faster than expected, Toyota officials say, and the company is hard at work on rolling out EVs in various markets. Details of the merger, including shareholding ratios, the company name and its structure will be worked out over the next 18 months, the companies said. They aim to sign a definitive agreement by early next year and close the transaction by the end of 2024. The deal still needs shareholdersÂ’ and regulatory approval.

Toyota retires robots in favor of humans to improve automaking process

Sat, 12 Apr 2014Mitsuru Kawai is overseeing a return to the old ways at Toyota factories throughout Japan. Having spent 50 years at the Japanese automaker, Kawai remembers when manual skills were prized at the company and "experienced masters used to be called gods, and they could make anything." Company CEO Akio Toyoda personally chose Kawai to develop programs to teach workers metalcraft such as how to forge a crankshaft from scratch, and 100 workstations that formerly housed machines have been set aside for human training.

The idea is that when employees personally understand the fabrication of components, they will understand how to make better machines. Said Kawai, "To be the master of the machine, you have to have the knowledge and the skills to teach the machine." Lessons learned by the newly skilled workers have led to shorter production lines - in one case, 96percent shorter - improved parts production and less scrap.

Taking time to give workers the knowledge to solve problems instead of merely having them "feed parts into a machine and call somebody for help when it breaks down," Kawai's initiative is akin to that of Toyota's Operations Management Consulting Division, where new managers are given a length of time to finish a project but not given any help - they have to learn on their own. It's not a step back from Toyota's quest to build more than ten million cars a year; it's an effort to make sure that this time they don't sacrifice quality while making the effort. Said Kawai, "We need to become more solid and get back to basics."

1980 toyota celica gt hatchback 2-door 2.2l

1980 toyota celica gt hatchback 2-door 2.2l 1982 toyota celica gt

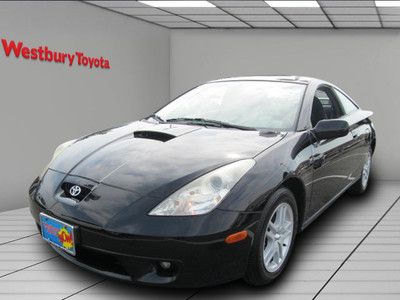

1982 toyota celica gt 3dr lb gt au coupe cd am/fm stereo bucket seats westbury toyota

3dr lb gt au coupe cd am/fm stereo bucket seats westbury toyota 2000 toyota celica gt hatchback 2-door 1.8l

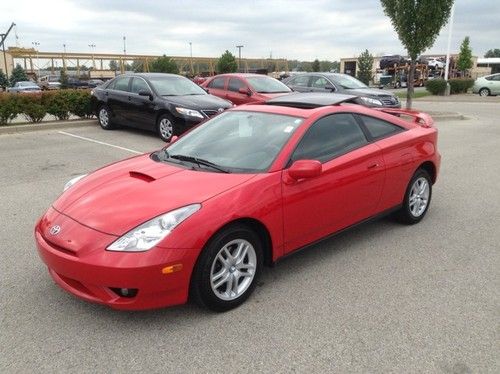

2000 toyota celica gt hatchback 2-door 1.8l 2003 toyota celica gt

2003 toyota celica gt 2001 toyota celica gt hatchback 2-door 1.8l

2001 toyota celica gt hatchback 2-door 1.8l