4dr Sdn Sedan Automatic 2.4l Dohc Vvt-i 16-valve Titanium Metallic on 2040-cars

Cordova, Tennessee, United States

For Sale By:Dealer

Engine:2.4L 2362CC l4 ELECTRIC/GAS DOHC Naturally Aspirated

Body Type:Sedan

Fuel Type:ELECTRIC/GAS

Transmission:Automatic

Warranty: Vehicle does NOT have an existing warranty

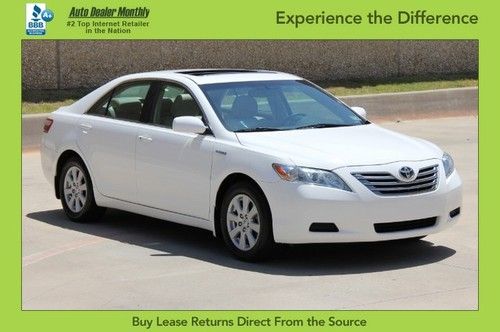

Make: Toyota

Model: Camry

Power Options: Air Conditioning, Power Door Locks, Power Windows

Trim: Hybrid Sedan 4-Door

Doors: 4

Drive Type: FWD

Engine Description: 2.4L DOHC VVT-I 16-VALVE

Mileage: 139,165

Number of Doors: 4

Sub Model: 4dr Sdn

Exterior Color: Tan

Number of Cylinders: 4

Interior Color: Gray

Toyota Camry for Sale

4dr sdn sedan automatic 2.4l dohc vvt-i 16-valve classic silver metallic

4dr sdn sedan automatic 2.4l dohc vvt-i 16-valve classic silver metallic Classic 1990 toyota camray v6 le, real clean car, needs transmission repaired(US $1,500.00)

Classic 1990 toyota camray v6 le, real clean car, needs transmission repaired(US $1,500.00) 1998 toyota camry le sedan 4-door 2.2l(US $2,999.99)

1998 toyota camry le sedan 4-door 2.2l(US $2,999.99) 2009 toyota camry le sedan 4-door 2.4l

2009 toyota camry le sedan 4-door 2.4l No reserve hybrid navigation moonroof bluetooth heated non smoker clean carfax

No reserve hybrid navigation moonroof bluetooth heated non smoker clean carfax Se 2.5l cd front wheel drive power steering 4-wheel disc brakes brake assist abs(US $14,877.00)

Se 2.5l cd front wheel drive power steering 4-wheel disc brakes brake assist abs(US $14,877.00)

Auto Services in Tennessee

Wurster`s Foreign Car Repair ★★★★★

White`s Tire & Auto Care ★★★★★

Watsons Auto Sales Warren County ★★★★★

Victory Motors ★★★★★

Valdez Motorsport ★★★★★

Toyota of Kingsport ★★★★★

Auto blog

Ford tops GM in US vehicle sales in May, driven by fleets

Thu, Jun 1 2017DETROIT - Ford, bolstered by heavy sales to fleet customers, surpassed General Motors in US new vehicle sales in May, according to figures reported Thursday. Ford said May sales rose 2.2 percent from a year ago to 241,126 units. GM sales dropped 1.3 percent to 237,364. GM said it had been trimming sales of heavily discounted vehicles to car rental companies. Such fleet sales made up about 19 percent of its total sales in May. Ford's fleet sales rose 8.4 percent, representing more than 34 percent of total sales. The industry average is around 20 percent. Analysts had expected mixed results for the industry, with sales likely propped up by heavy discounts. Fiat Chrysler Automobiles said May sales dipped 0.9 percent to 193,040. Toyota's US sales dropped 0.5 percent to 218,248. Nissan said US sales in May rose 3.0 percent, to 137,471. After demand fell in March and April, analysts estimated May sales at just over 1.5 million. The seasonally adjusted annual rate of sales in May was estimated at 16.8 million to 16.9 million vehicles, about the same as April. A year earlier, sales stood at 17.55 million vehicles. Early reports indicated that sales over the three-day Memorial Day weekend were helped by heavy discounts. "While demand for new vehicles is still relatively strong, it's a bit of smoke and mirrors," said Jessica Caldwell, executive director of industry analysis at Edmunds, the car shopping website. Manufacturers and dealers "really pushed the deals over the holiday weekend to prop up their May numbers," she said. "Incentives were up sharply, and it seems automakers are putting more cash on the hood to nudge car shoppers to buy versus lease." General Motors dealers were offering discounts of up to $12,000 on the full-size Chevrolet Silverado pickup, while some dealer discounts on Ford Motor Co's F-series pickups were more than $10,000 on 2017 models and more than $14,000 on leftover 2016 models. The 2017 model year started eight months ago. Reporting by Paul LienertRelated Video: This content is hosted by a third party. To view it, please update your privacy preferences. Manage Settings. Earnings/Financials Chrysler Fiat Ford GM Nissan Toyota US

World Car Awards finalists snub American-branded vehicles — except for Bronco

Fri, Feb 2 2024The list of World Car Awards has been whittled down to 10 finalists, but only one American brand — Ford — appears among the remaining nine carmakers for this yearÂ’s top award. The Bronco is there, and it also is balloted as a finalist in the design category. The other categories are performance car, urban car, electric vehicle and luxury model. Each category has five finalists except World Car, which has 10. One brand conspicuous by its absence in any category: Tesla. The winner in each is scheduled to be crowned March 27 at the New York International Auto Show in Manhattan. This year marks the 20th year of the World Car Awards and the partnership with the New York show. The selection process involves 100-plus automotive journalists from 29 countries who vote, as they review and test-drive the eligible vehicles for the 2024 awards. Their journey is captured virtually on World Car TV. If youÂ’re counting, the brands that appear most on the six finals lists are Mercedes-Benz (four times), BMW (also four), Hyundai (three), and Volvo (three). HereÂ’s the full listing. A video clip showing all of them is here: World Car -BYD Seal / Atto 4 -Ford Bronco -Hyundai Kona / Kona Electric -Hyundai Santa Fe -Kia EV9 -Mazda CX-90 -Subaru Crosstrek -Toyota Prius -Volkswagen ID.7 -Volvo EX30 World Car Design of the Year Ford Bronco Ferrari Purosangue Toyota Prius Volvo EX30 Zeekr X 2024 World Electric Vehicle BMW i5 Kia EV9 Mercedes-Benz EQE SUV Volkswagen ID.7 Volvo EX30 2024 World Luxury Car - BMW 5 Series / i5 - Lexus LM - Mercedes-Benz CLE - Mercedes-Benz E-Class - Mercedes-Benz EQE SUV 2024 World Urban Car - Abarth 500e - BYD Dolphin - Lexus LBX - Suzuki Fronx - Volvo EX30 2024 World Performance Car - BMW M2 - BMW XM - Ferrari Purosangue - Hyundai Ioniq 5 N - Porsche Cayenne Turbo E-Hybrid

Toyota i-Road is no less strange in the flesh

Tue, 05 Mar 2013We've seen plenty of three-wheeled creations in our day, but none quite like the Toyota i-Road Concept. The "personal mobility vehicle" offers seating for two with driver and passenger positioned in a tandem position. While that may sound more like a motorcycle than a car, the closed cockpit means riders don't need a helmet. The design also takes a page from the 2008 Peugeot HyMotion3 Concept with an articulating front suspension that allows the driver to lean through corners thanks to "Active Lean" self-balancing technology. Unlike the funky Pug, however, the i-Road is a fully electric plug-in vehicle.

While there are just five-horsepower on hand from an electric motor, the i-Road should serve up a range of around 30 miles thanks to its lithium-ion battery, and Toyota claims the cells can be topped off in three hours with a "conventional domestic power supply." Sounds majestic. Take in the full press release below.