2005 Toyota Camry Le Sedan 4-door 2.4l on 2040-cars

Louisville, Kentucky, United States

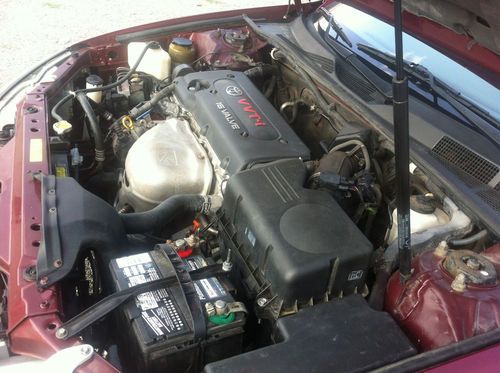

Engine:2.4L 2362CC l4 GAS DOHC Naturally Aspirated

Vehicle Title:Rebuilt, Rebuildable & Reconstructed

Body Type:Sedan

Fuel Type:GAS

For Sale By:Dealer

Sub Model: le

Make: Toyota

Exterior Color: Red

Model: Camry

Interior Color: Gray

Trim: LE Sedan 4-Door

Warranty: Vehicle does NOT have an existing warranty

Drive Type: FWD

Number of Cylinders: 4

Options: CD Player

Safety Features: Anti-Lock Brakes, Driver Airbag, Passenger Airbag, Side Airbags

Power Options: Air Conditioning, Cruise Control, Power Locks, Power Windows, Power Seats

Number of Doors: 4

Disability Equipped: No

Mileage: 88,954

up for sale

Toyota Camry for Sale

2000 toyota camry le sedan 4-door 2.2l(US $5,200.00)

2000 toyota camry le sedan 4-door 2.2l(US $5,200.00) 1999 toyota camry le sedan 4-door 2.2l *******no reserve********* 50,xxxx miles

1999 toyota camry le sedan 4-door 2.2l *******no reserve********* 50,xxxx miles Clean carfax warranty one owner dealer inspected ac automatic

Clean carfax warranty one owner dealer inspected ac automatic 2002 toyota camry, no reserve,leather,power roof, climate control,6 disc cd

2002 toyota camry, no reserve,leather,power roof, climate control,6 disc cd 2004 toyota camry le sedan 4-door 2.4l - one owner / new tires & brakes

2004 toyota camry le sedan 4-door 2.4l - one owner / new tires & brakes 2011 toyota camry se black v6 leather navigation back up camera

2011 toyota camry se black v6 leather navigation back up camera

Auto Services in Kentucky

Toyota Of Hopkinsville ★★★★★

Tire Discounters ★★★★★

Snake`s Body Shop ★★★★★

McCarty`s Towing ★★★★★

Lindale Auto Parts ★★★★★

Larry Fannin Chevrolet Buick GMC ★★★★★

Auto blog

Toyota recalls 690,000 Tacoma trucks for rusty leaf springs, fire risk

Mon, 29 Sep 2014Toyota has announced that it will be issuing a recall of 690,000 Tacoma pickups from model years 2005 through 2011. The affected vehicles include both the four-wheel-drive model and the two-wheel-drive PreRunner (but not the standard 4x2 pickups), which may have a rather serious problem with their rear suspensions.

In some cases, corrosion and stress could cause one of the three or four leaves in the rear suspension's leaf springs to fracture. While the trucks can still be driven with a broken leaf, Toyota is concerned that it could move out of position and impact other components in the rear of the truck, with a particular focus on the fuel tank. Needless to say, but a piece of metal continuously impacting anything, let alone the fuel tank, is cause for concern.

As of this writing, there have been no reports of crashes, injuries, fires or deaths due to this problem, although that won't stop Toyota from informing all affected customers of the issue. Those 690,000 owners will need to report in to dealers for inspections and, if necessary, repairs.

Toyota struggling in Latin American market, attempting recovery

Fri, 30 Aug 2013With uncertainty in the US and Chinese markets, automakers are scrambling to rev up their efforts in what were traditionally secondary markets. Take Toyota's efforts in Latin America. A recent story from The Wall Street Journal highlights the Japanese brand's push in the southern hemisphere, particularly in Brazil, where it has expanded its operations and installed new executives with a greater range of powers, all in a bid to grab a bigger slice of the ever-growing South American pie.

South America is dominated by General Motors, Fiat and Volkswagen, which maintain a combined 60 percent of the market share - Toyota holds a mere 4.5 percent. The WSJ spoke with Steve St. Angelo, Toyota's boss in Latin America, who said, "We are playing catch up, but we're catching up fast. We now have the resources to give the region the attention it really needs and deserves."

That attention includes an all-new, locally produced small car called the Etios. As bewildering as it seems, Toyota wasn't competing in the low-cost economy car market in South America. With the Etios, which arrived in September of 2012, its sales in the first seven months of 2013 are up 75 percent.

Toyota retires robots in favor of humans to improve automaking process

Sat, 12 Apr 2014Mitsuru Kawai is overseeing a return to the old ways at Toyota factories throughout Japan. Having spent 50 years at the Japanese automaker, Kawai remembers when manual skills were prized at the company and "experienced masters used to be called gods, and they could make anything." Company CEO Akio Toyoda personally chose Kawai to develop programs to teach workers metalcraft such as how to forge a crankshaft from scratch, and 100 workstations that formerly housed machines have been set aside for human training.

The idea is that when employees personally understand the fabrication of components, they will understand how to make better machines. Said Kawai, "To be the master of the machine, you have to have the knowledge and the skills to teach the machine." Lessons learned by the newly skilled workers have led to shorter production lines - in one case, 96percent shorter - improved parts production and less scrap.

Taking time to give workers the knowledge to solve problems instead of merely having them "feed parts into a machine and call somebody for help when it breaks down," Kawai's initiative is akin to that of Toyota's Operations Management Consulting Division, where new managers are given a length of time to finish a project but not given any help - they have to learn on their own. It's not a step back from Toyota's quest to build more than ten million cars a year; it's an effort to make sure that this time they don't sacrifice quality while making the effort. Said Kawai, "We need to become more solid and get back to basics."