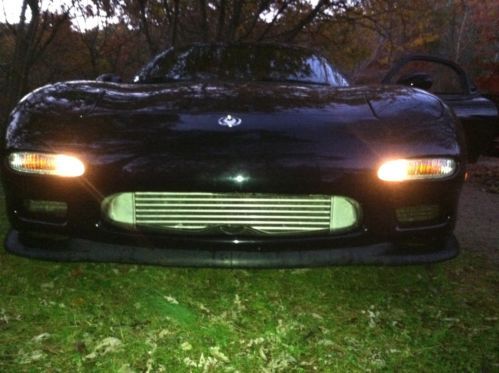

1993 Mazda Rx7 R1 Fd // Rare Collectable 93 Rx-7//3rd Gen.// Super Clean Rx 7/ on 2040-cars

Mazda RX-7 for Sale

Auto blog

2019 Mazda CX-5 Turbo Drivers' Notes Review | More power, more love

Wed, Feb 20 2019The second-gen Mazda CX-5 has been on sale since 2017, but the big news for this year is the addition of a new turbocharged 2.5-liter inline-four. The engine — dubbed Skyactiv-G — is shared with the Mazda6 and the Mazda CX-9 three-row crossover and makes 227 horsepower and 310 pound-feet of torque on regular gas and up to 250 hp when running premium fuel. Fuel economy for the new engine is rated at 22 mpg city, 27 mpg highway and 24 mpg combined. The engine is only available with all-wheel drive, but the extra grunt means fuel economy is down from the naturally-aspirated 2.5-liter inline-four (24 city, 30 highway and 26 combined). The new engine is wrapped in the same familiar package we've seen for the past couple of years, but is exclusive to the range-topping Grand Touring Reserve and Signature trim levels. This particular test car was a Signature, which starts at $37,935 before options. For reference, a base, front-wheel drive CX-5 Sport starts at $25,395. Standard features on the CX-5 Signature include 19-inch wheels, LED lighting, rain-sensing wipers, leather seating, heated front and rear seats, a heated steering wheel, adaptive cruise control, proximity entry and push-button start, and a Bose audio system. Options on this Soul Red ($595) model are restricted to accessory items: $70 for a cargo mat, $125 for all-weather floor mats, $400 for illuminated door sills, $125 for a rear-bumper guard and $250 for a retractable cargo cover. The final MSRP comes in just below $40,000. Our contributor Ben Hsu had high praise for the CX-5 turbo in our recent first-drive review. Now the rest of us have had a crack at it. Editor-in-Chief Greg Migliore: I love the CX-5's looks and driving dynamics. It's a sporty Mazda tailored to the crossover segment. This one, done up in Soul Red Crystal Metallic (what a name) and Signature trim with smokey 19-inch wheels, looks great. The Skyactiv-G four-cylinder with 227 hp (on 87 octane) and 310 pound-feet of torque makes for a brisk driving experience. In Sport mode, it's almost more eager than I want it to be. The main downside is the interior. The materials are just fine, and the infotainment is a little clunky to use. It takes a few more moves than I'd like to change the radio station. Also, major demerits for not being able to put a rear-facing car seat in the middle. Considering young families are a target market for this, that is not ideal.

Mazda6 sees gains in ugly month for midsize sedans

Thu, Jul 5 2018Though June overall wasn't a terrible month for automaker sales, at least for the most part, it was pretty hideous for midsize family sedans. Basically every single model in the segment saw declining numbers including the Subaru Legacy, Nissan Altima, Ford Fusion, Volkswagen Passat, and even perennial volume sellers such as the Honda Accord and Toyota Camry. All of these cars are down in year-to-date numbers, too. But there's one bright spot, and it comes from Mazda. Mazda reports that the Mazda6 actually had a really good month. It sold 3,204 examples of the family sedan in June 2018, compared with 2,360 in June of last year. That's a nearly 36 percent increase month-over-month. It was also enough to bump Mazda6 sales for 2018 ahead of 2017's numbers through June. Those numbers also put the Mazda6 ahead of the Volkswagen Passat for June, and just 20 vehicles shy of the Subaru Legacy. Admittedly, these are still small numbers all around. In the same month, Honda sold over 26,000 Accords, and Toyota sold about 27,000 Camrys. Sales of Mazda's other vehicles also indicate that crossovers really are the new hotness. The CX-5 sold a whopping (relatively) 12,710 units. The CX-3 and CX-9 sold about 2,300 examples each, which is below both Mazda3 and Mazda6, but both crossovers gained more this month and over the year than both cars. Mazda3 is actually down this month and overall. All of this also seems to give some credence to Ford's decision to move away from traditional sedans. Still, for fans of more conventional cars, it's a bit heartening to see that more niche players can find some success with the design. We're also pleased to see such an excellent sedan recognized with actual buyers. Related Video: This content is hosted by a third party. To view it, please update your privacy preferences. Manage Settings. Featured Gallery 2018 Mazda6 Signature View 17 Photos Image Credit: Mazda By the Numbers Mazda Sedan

Mazda and Lexus crowned with KBB 5-Year Cost To Own awards

Tue, 12 Feb 2013We report on a lot of awards, some of which are given out based on more solid criteria than others. This one, the Kelley Blue Book 5-Year Cost to Own awards, seems like one that new car shoppers should pay attention to.

The cost of a car goes far beyond what you pay for the actual metal, leather and rubber at the point of purchase. Fuel, insurance, maintenance and repair costs, and the cost of fees from the state and financing will all weigh on your wallet while you own the car. That's not even taking into account the biggest cost: depreciation, or the amount of money you lose based on what your car is worth years from now versus the day you bought it.

KBB tracks these sorts of things, and they've compiled a list of winners for 2013 models. On the brand level, Mazda and Lexus earn the 5-Year Cost to Own award for having the lowest overall projected five-year totals (though, curiously, we note that Mazda and Lexus each had only one segment winner). There are lots of winners for all the various segments, so we'll just pick out a few surprising ones to share and you can view the rest here.

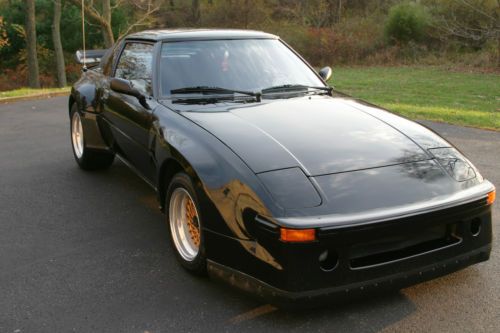

1989 mazda rx-7 convertible convertible 2-door 1.3l

1989 mazda rx-7 convertible convertible 2-door 1.3l 1982 custom mazda rx7, 80's show car

1982 custom mazda rx7, 80's show car 1989 mazda rx-7 turbo fc3s turbo ii rx7

1989 mazda rx-7 turbo fc3s turbo ii rx7 Mazda rx 7 v8

Mazda rx 7 v8 1993 mazda rx-7 r1 coupe 2-door 1.3l

1993 mazda rx-7 r1 coupe 2-door 1.3l 1982 mazda rx-7

1982 mazda rx-7