1994 Mazda Mpv Passenger Standard Passenger Van 3-door 3.0l on 2040-cars

Union, New Jersey, United States

Body Type:Standard Passenger Van

Vehicle Title:Clear

Engine:3.0L 2954CC V6 GAS SOHC Naturally Aspirated

Fuel Type:GAS

For Sale By:Private Seller

Number of Cylinders: 6

Make: Mazda

Model: MPV

Trim: Passenger Standard Passenger Van 3-Door

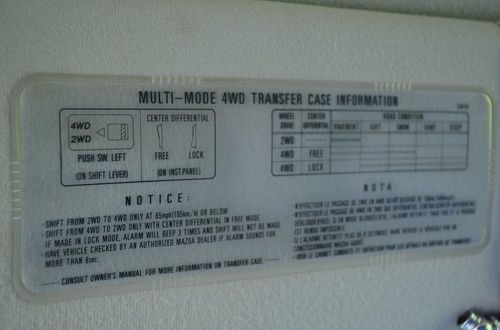

Options: 4-Wheel Drive, CD Player

Drive Type: 4WD

Safety Features: Driver Airbag, Passenger Airbag

Mileage: 142,733

Power Options: Air Conditioning, Cruise Control, Power Locks, Power Windows

Exterior Color: Navy

Interior Color: Gray

Up for sale is a 1994 Mazda MPV 4WD MADE IN JAPAN. It has 142,733 highway miles with a strong and 4-WHEEL DRIVE ENGINE. It's running VERY well for its age and is well taken care of. It has been our family car for a long time so there's typical minor scratches/marks/dings. My dad oil changes it himself every 3 months. The tires are clearly still pretty new with a new spare tire underneath. The exterior is navy blue and the interior is gray with cloth seats. The back seats are both fold-able to increase storage space. Power windows and power locks with cruise control. This is a very clean SUV as you can see, like I said, it's well taken care of. My dad gets it car washed and shined almost every 1-2 weeks. ****PLEASE SEE DETAILED PICTURES*****

Home: 908-964-6696 (If you want to leave a message)

******I HAVE MORE PICTURES; SEND ME AN E-MAIL*********

Mazda MPV for Sale

2002 mazda mpv es standard passenger van 4-door 3.0l ! no reserve !

2002 mazda mpv es standard passenger van 4-door 3.0l ! no reserve ! 2004 silver/gray mazda mpv lx(US $5,500.00)

2004 silver/gray mazda mpv lx(US $5,500.00) 2002 mazda mpv lx standard passenger van 3-door 3.0l

2002 mazda mpv lx standard passenger van 3-door 3.0l Only 81k miles pre-owned dealer trade must sell must sell

Only 81k miles pre-owned dealer trade must sell must sell 2006 mazda mpv es mini passenger van 4-door 3.0l(US $9,499.00)

2006 mazda mpv es mini passenger van 4-door 3.0l(US $9,499.00) 1995 mazda mpv, no reserve

1995 mazda mpv, no reserve

Auto Services in New Jersey

Vitos Auto Electric ★★★★★

Town Auto Body ★★★★★

Tony`s Auto Svc ★★★★★

Stan`s Garage ★★★★★

Sam`s Window Tinting ★★★★★

Rdn Automotive Repair ★★★★★

Auto blog

Mazda files patents for a sequential twin-turbo setup

Fri, Dec 8 2017Mazda has a history of interesting engine technologies, from yesterday's rotary engine to tomorrow's compression ignition engine, and new patents show it still may have some internal combustion tricks up its sleeve. The one on display in these patents isn't especially new in concept, though. A sequential twin-turbocharger setup is something Mazda itself used on the third-generation RX-7. But it's something we haven't seen much of lately. It looks like it could have some possible advantages over older sequential systems, and it has some potential advantages for enthusiasts. First a quick and dirty primer for what makes a sequential twin-turbo system distinct from other twin-turbo systems. In many twin-turbo engines, there are simply two turbos that work together as one bigger turbo. They're the same size, and they spool up at the same time. With a sequential setup, at low rpm, a smaller turbocharger is spooled up first at low-rpm for quicker throttle response, and as the rpm and exhaust pressure increases, a valve opens up that allows a larger turbocharger to also spool up and provide high-rpm boost. That's basically how the Mazda design shown above functions. A big flap blocks off the larger turbocharger exhaust inlet, channeling all the exhaust to the smaller turbo. When more exhaust is available at high rpm, it looks like that flap opens up to spool up the big turbo, too. What's interesting here is that the way the turbochargers are packaged takes up less space than past systems. It looks like both turbos are contained in one unit that shares the same exhaust outlet, meaning the exhaust manifold could be kept simple and compact. In fact, the piping for compressed intake air could also be shared, reducing the amount of piping, which would further decrease the amount of materials and possible failure points. There are a number advantages of making this system smaller. The potential applications of the system are much greater, since it could fit in smaller cars with smaller engine bays. Making the system smaller also means that there won't be as much weight, which is important from both fuel economy and performance standpoints. Finally, the smaller setup likely uses fewer materials, which could make the system cheaper and thus easier to offer on a wider range of vehicles, or at least more profitable for Mazda.

Junkyard Gem: 1989 Mazda MX-6 GT Turbo

Fri, Nov 18 2016The Mazda MX-6 is best-known in the United States as the sibling (or maybe first cousin) of the Ford Probe, which almost became the successor to the Fox Mustang. The MX-6 and Probe were well-engineered and very quick for the era, but never enjoyed great American-market sales success. Here's a rare first-generation MX-6 GT that I photographed last week in a Denver self-service yard. 145 turbocharged horsepower was pretty good for 1989, when a new Honda Prelude Si had 135 horses and the far more expensive BMW 325i ($24,650 for the 325i coupe versus $14,499 for the MX-6 GT Turbo) had 168. This one doesn't have the optional four-wheel steering, but it does have the three-way adjustable suspension. If you drove a turbocharged car in 1989, you needed a nine-band equalizer with analog sliders on the radio. It was the law. It's not rusty, but at 205,575 miles it's worn out. This content is hosted by a third party. To view it, please update your privacy preferences. Manage Settings. The Japanese-market version was known as the Capella C2, and it boasted some great TV commercials. This content is hosted by a third party. To view it, please update your privacy preferences. Manage Settings. "A better value in high-performance luxury sports coupes comes from our intense commitment to your total satisfaction." As always, the US-market TV ads are less interesting than their Japanese counterparts. Related Video: Featured Gallery Junked 1989 Mazda MX-6 GT Turbo View 21 Photos Image Credit: Murilee Martin / AOL Auto News Mazda Coupe Classics

Tougher than steel: Wood pulp could make lighter auto parts

Tue, Aug 15 2017KYOTO, Japan — The global push among carmakers to make ever lighter vehicles is leading some auto suppliers in Japan to turn to what seems like an unlikely steel substitute — wood pulp. Japanese researchers and auto component makers say a material made from wood pulp weighs just one-fifth of steel and can be five times stronger. The material - cellulose nanofibers — could become a viable alternative to steel in the decades ahead, they say, although it faces competition from carbon-based materials, and remains a long way from being commercially viable.> Related: Jay Leno drives the Renew cannabis car — hemp you can't dent Reducing the weight of a vehicle will be critical as manufacturers move to bring electric cars into the mainstream. Batteries are an expensive but vital component, so a reduction in car weight will mean fewer batteries will be needed to power the vehicle, saving on costs. "Lightweighting is a constant issue for us," said Masanori Matsushiro, a project manager overseeing body design at Toyota. "But we also have to resolve the issue of high manufacturing costs before we see an increased use of new, lighter-weight materials in mass-volume cars."A NEW PROCESS Researchers at Kyoto University and major parts suppliers such as Denso Corp, Toyota's biggest supplier, and DaikyoNishikawa Corp, are working with plastics incorporated with cellulose nanofibers — made by breaking down wood pulp fibers into several hundredths of a micron (one thousandth of a millimeter). Cellulose nanofibers have been used in a variety of products ranging from ink to transparent displays, but their potential use in cars has been enabled by the "Kyoto Process," under which chemically treated wood fibers are kneaded into plastics while simultaneously being broken down into nanofibers, slashing the cost of production to roughly one-fifth that of other processes. "This is the lowest-cost, highest-performance application for cellulose nanofibers, and that's why we're focusing on its use in auto and aircraft parts," Kyoto University Professor Hiroaki Yano, who is leading the research, told Reuters in an interview. The university, along with auto parts suppliers, are currently developing a prototype car using cellulose nanofiber-based parts to be completed in 2020.