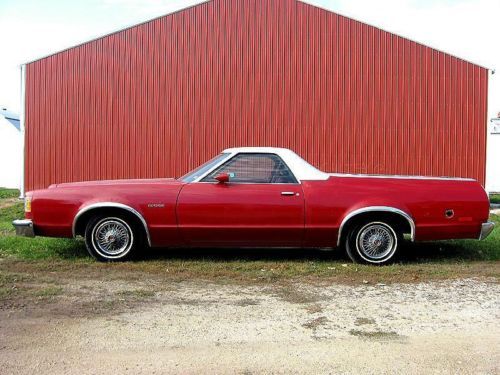

Engine:351

Year: 1957

Make: Ford

Trim: Plain

Model: Ranchero

Mileage: 1,000

Drive Type: rwd

|

This is a 1957 Ranchero. Its a nice project. Needs new floor pan. Winning bidder is responsible for shipping or local pickup.

|

Ford Ranchero for Sale

Fresh body on restoration excellent condition, 92 mustang 302 with mustang 5 spd(US $12,500.00)

Fresh body on restoration excellent condition, 92 mustang 302 with mustang 5 spd(US $12,500.00) 1977 ford ranchero gt - all original

1977 ford ranchero gt - all original 1964 ford ranchero 61k miles(US $6,600.00)

1964 ford ranchero 61k miles(US $6,600.00) 1973 ford ranchero only 25k miles 351 cleveland motor v8 rust free garage kept(US $17,900.00)

1973 ford ranchero only 25k miles 351 cleveland motor v8 rust free garage kept(US $17,900.00) 1979 ford ranchero

1979 ford ranchero 1974 ford ranchero gt 7.5l 460 big block(US $10,000.00)

1974 ford ranchero gt 7.5l 460 big block(US $10,000.00)

Auto Services in Texas

Xtreme Customs Body and Paint ★★★★★

Woodard Paint & Body ★★★★★

Whitlock Auto Kare & Sale ★★★★★

Wesley Chitty Garage-Body Shop ★★★★★

Weathersbee Electric Co ★★★★★

Wayside Radiator Inc ★★★★★

Auto blog

Ken Block hoons his Ford F-150 RaptorTrax on the slopes

Wed, 08 Oct 2014Ken Block drives Fords. Hoons the heck out of 'em, actually. Mostly Fiestas, but also the occasional Focus or Mustang. But earlier this year, the Gymkhana guru revealed his baddest Ford yet: an F-150 SVT Raptor on tracks. And true to form, here he is putting it to the test in the latest video from Monster Energy and Hoonigan Racing.

Filmed at Baldface Lodge in Nelson, BC, the video pairs Block up with snowboarders Zak Hale and Ethan Deiss for some deep-powder action. You'll want to watch the video for yourself, but the bottom line is that the RaptorTrax beats the heck out of waiting on line for the ski lift. It's enough to make us start to look forward to winter... almost.

Ford blows up Takata airbag recall by over 447k vehicles

Thu, Dec 18 2014Ford is the latest automaker to announce an expansion to its Takata driver-side airbag inflator recall, and the latest increase adds an additional 447,310 vehicles to the nationwide total. The company says that this expansion comes at the request of the National Highway Traffic Safety Administration. The expanded recall campaign covers: The 2005-2008 Ford Mustang built between August 18, 2004, and June 25, 2007, at the at Flat Rock Assembly Plant The 2005-2006 Ford GT built between February 11, 2005, and January 30, 2006, at the at the Wixom Assembly Plant As of December 18, Ford knows of a total of 502,489 vehicles in need of replacement driver side inflators. Of those, 462,911 are in the US, 27,516 in Canada, 7,578 in Mexico and 4,484 outside of North America. The automaker is aware of one injury that may be related to these exploding parts. Earlier in December, the automaker issued an expanded recall covering passenger side Takata airbag inflators for the Ranger pickup and Ford GT. When taking this into account, the grand total of Ford products with inflators that need replacement for the driver or passenger side is 538,977 vehicles. Scroll down to read the company's full announcement of this enlarged safety campaign. FORD EXPANDS TAKATA DRIVER-SIDE AIRBAG INFLATOR SAFETY RECALL DEC 18, 2014 | DEARBORN, MICH. At the request of the National Highway Traffic Safety Administration, Ford is expanding its recall on Takata driver-side airbag inflators. This recall includes approximately 502,489 vehicles, an addition of approximately 447,310 vehicles. This brings the total number of Ford vehicles being recalled for Takata airbag inflators to approximately 538,977. This expanded recall includes 2005-2008 Ford Mustang vehicles built Aug. 18, 2004 to June 25, 2007 at Flat Rock Assembly Plant and 2005-2006 Ford GT vehicles built Feb. 11, 2005 to Jan. 30, 2006 at Wixom Assembly Plant. As of Dec. 18, 2014, Ford is aware of approximately 462,911 vehicles in the United States and federalized territories, approximately 27,516 in Canada and approximately 7,578 in Mexico affected by this recall. Approximately 4,484 additional vehicles outside of North America are also included in this action. Ford is aware of one accident with an injury that may be related to this condition. Dealers will replace the airbag inflator at no cost to the customer.

How Ford switched gears for the all-new F-150

Fri, Mar 6 2015Editor's Note: This story is authored by Julia Halewicz, a senior editor with AOL's Custom Solutions Group. She holds a Masters in Journalism from NYU and has spent her career as an editor of various newspapers, magazines and digital outlets. Last year on the Friday before Labor Day, the 2014 Ford F-150 pickup truck came off the Dearborn assembly line for the last time. After the last seam was welded, the F-150 that had been so beloved by American consumers would begin the transition from traditional steel manufacturing to an aluminum body, and the second phase of Ford's 2007 blueprint for sustainability would begin. Jobs would be created, and Ford would deliver a stronger product to its consumers. It was a moment Ford would call the biggest in the company's 111-year history. Breaking The Mold For some, the change was almost unfathomable. How could a truck be made with aluminum, and why change what clearly was working very well for the company? "We have a saying at Ford that leaders lead," said Doug Scott, the company's truck group marketing manager. "This was an ideal product to make with aluminum-alloy, because lightweighting made so much sense for a truck, because the extent to which you could take weight out of a truck, you could add more value to the customer in terms of more towing, more payload, more durability, more efficiency – so again all this required us to be out in front further out in front that we normally would be to make sure that we would deliver on all those expectations." Ford began the planning process about five years before the first aluminum F-150 would come to market. The company had a lot of questions. What was customer acceptance of aluminum, could they build the truck, and could the truck be repaired out in the field? Finally, Ford needed to determine if there were enough materials available to support the demand for the F-Series. Aluminum vehicles aren't unusual, but had never been built on the scale of the F-150 – approximately one every minute. Ford created two prototypes to determine if the product would meet and exceed consumer expectations. Any change to the vehicle had to be justified in performance, safety and economy. An aluminum truck needed to be safer, lighter, have increased payload, haul more, and have improved fuel efficiency. After driving the prototypes, Ford knew it was ready to move forward. Once the aluminum truck was ready to build, the next challenge was quickly transforming the plant.

2040Cars.com © 2012-2025. All Rights Reserved.

Designated trademarks and brands are the property of their respective owners.

Use of this Web site constitutes acceptance of the 2040Cars User Agreement and Privacy Policy.

0.039 s, 7967 u