Ford: Mustang on 2040-cars

Villa Ridge, Missouri, United States

1968 Ford Mustang Convertible 289 / Automatic. The Factory 286 Engine and automatic transmission have been rebuilt with low mileage. It is non power 4 wheel drum brakes and no power steering. It has been repainted but does have scratches and some chips (driver Quality) and floor boards replaced. This Mustang would be a perfect weekend cruiser, parade car, or for local car shows. To be an all-weather car it with need the convertible top replaced as it is in rough shape with holes and tears. Great Driver but not perfect. Has had many new parts: Front and rear bumpers Tail lights and bezels Lots of trim pieces Seats covers Door panels Convertible boot Heater blower motor.

Please let me know if you have any questions by sending me a message at : hollisrezone8@netzero.com

Ford Mustang for Sale

Ford: mustang 2-door convertible(US $14,550.00)

Ford: mustang 2-door convertible(US $14,550.00) Ford: mustang roush(US $11,600.00)

Ford: mustang roush(US $11,600.00) Ford: mustang svt cobra(US $11,800.00)

Ford: mustang svt cobra(US $11,800.00) 2015 ford mustang gt premium(US $12,155.00)

2015 ford mustang gt premium(US $12,155.00) Ford: mustang lx(US $7,000.00)

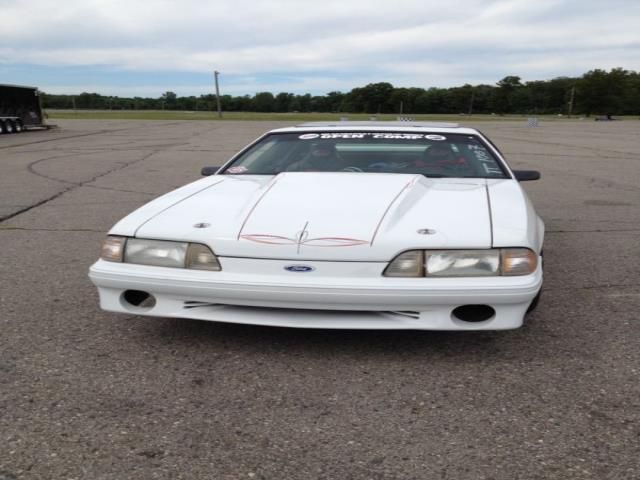

Ford: mustang lx(US $7,000.00) Ford: mustang full race or por street(US $19,999.00)

Ford: mustang full race or por street(US $19,999.00)

Auto Services in Missouri

Western Tire & Auto ★★★★★

Valvoline Instant Oil Change ★★★★★

St Louis Car & Credit ★★★★★

St Louis Auto Parts Co ★★★★★

Specialty Automotive ★★★★★

SL Services Inc ★★★★★

Auto blog

BMW V8-powered Ford Model A is the definition of Hot Rod

Thu, 20 Jun 2013Today, hotrodding has a pretty staid definition. Take one classic American car, add one classic American V8, sprinkle with tire smoke and you pretty much have every hot rod to roll out of a shop in the last 40 years. Mike Borroughs knows it wasn't always this way. Once upon a time, getting your bucket to go faster meant grabbing whatever parts were lazing about the yard, bolting them together with a bit of ingenuity and laughing your way down the quarter mile. It's in that spirit that Burroughs built his 1928 Ford Model A.

Rather than turn to the tired flathead or the common Chevrolet small block, Burroughs plucked a 4.0-liter V8 from a 1995 BMW 7 Series. With 300 horsepower and 300 pound-feet of torque, the engine has no trouble shuffling the old A around town. He had to build a custom chassis to get everything to cooperate, but the result is a 1,500-pound heathen that looks built to harass dry lake beds. You can check it out in the video below. Be warned, the soundtrack by Hanni el Khatib may not be safe for work - awesomeness of this caliber rarely is.

2016 Ford Focus RS to start at $35,730? [UPDATE]

Wed, Jul 29 2015UPDATE: Unsurprisingly, Ford declined to comment on the pricing shown on the consumer page, with spokesman Aaron Miller telling Autoblog that the Blue Oval does "not comment on pricing speculation." The webpage showing the $35,730 figure has since been pulled down. We love it when automakers make little, tiny mistakes. You know, not the big stuff that leads to recalls, but the small things, like accidentally releasing pricing of a hotly anticipated model via its US consumer website. Such a thing has apparently happened to Ford, as Jalopnik's Car Buying sub-blog has uncovered a page on the site listing the starting price of the 2016 Focus RS. The cost of entry for the 345-horsepower, all-wheel-drive, torque-vectoring hot hatchback is $35,730, according to the website. That's $1,035 more than the base Subaru WRX STI, although it's $865 less than the Volkswagen Golf R. Considering the RS outguns both models by a very significant margin – 40 horsepower over the STI and 47 over the Golf R – that price seems very agreeable. If it's correct, that is. Aside from showing the RS' starting price, the page also gives us a glimpse into the options sheet. There's an RS2 equipment level that adds $2,795 to the base price along with navigation and leather Recaro seats, an $895 sunroof, and a 19-inch wheel and Michelin Pilot Sport Cup tire package for $1,990 (or just $1,395 for the 19s alone). Some fiddling with the quite incomplete configurator – there are no images and the overall design is rather glitchy – revealed a max price of $42,275. We've reached out to Ford for confirmation of the pricing information displayed. Head into Comments and let us know what you think of the pricing. Has Ford hit it out of the park by slotting in a more powerful competitor between the Subaru and Volkswagen? Were you expecting a higher price (like your author), or is this still too much money for a jumped-up Focus? Related Video:

Ford profiles surprisingly affluent Focus ST buyers

Fri, 08 Nov 2013It comes as no surprise when Ford says that 32-percent of Focus ST buyers are under 35, but we weren't expecting this: the average annual salary of Focus ST buyers is $127,000. Twenty-two percent of non-ST Focus buyers are under 35, while their average annual salary is $67,000.

We like the Focus ST because it has 252 horsepower, is genuinely fun to drive and offers great value for performance-minded car enthusiasts; facts that are not lost on customers, it seems. Ford says that the Focus ST has the highest percentage of conquest sales for a non-hybrid model it sells, and that the top-four trade-ins are from Honda, Chevrolet, Mazda and Toyota. Demand for the hot Focus is strongest in Los Angeles, Detroit, Houston and Orlando.

"[The Focus ST is] having this kind of halo effect for other vehicles we'd hoped for when we invested in the ST brand," says John Felice, vice president of US marketing, sales and service, because it's helping to boost sales of other Ford vehicles.