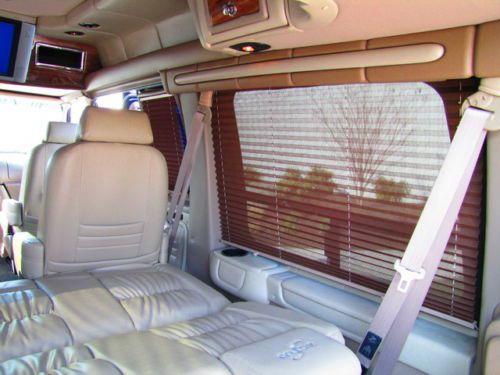

Great Conversion Luxury High Top Van!sherrod!low Mileage!navigation!warranty!06 on 2040-cars

Philadelphia, Pennsylvania, United States

Ford E-Series Van for Sale

Wheel chair lift , rv bus(US $6,000.00)

Wheel chair lift , rv bus(US $6,000.00) 2010 ford e-250 base extended cargo van 3-door 4.6l(US $8,900.00)

2010 ford e-250 base extended cargo van 3-door 4.6l(US $8,900.00) 2002 ford econoline passenger van bulletproof(US $30,000.00)

2002 ford econoline passenger van bulletproof(US $30,000.00) 2006 e350 16ft box truck ramp v8 strong runner like new tires nice fl(US $7,750.00)

2006 e350 16ft box truck ramp v8 strong runner like new tires nice fl(US $7,750.00) E-series van wheelchair van ford e 250 ricon lift electric powered no reserve

E-series van wheelchair van ford e 250 ricon lift electric powered no reserve Xlt 15 passenger super duty cloth 5.4l v8 running boards warranty we finance

Xlt 15 passenger super duty cloth 5.4l v8 running boards warranty we finance

Auto Services in Pennsylvania

Young`s Auto Body Inc ★★★★★

World Class Transmission Svc ★★★★★

Wood`s Locksmithing ★★★★★

Trust Auto Sales ★★★★★

Steele`s Truck & Auto Repair ★★★★★

South Hills Lincoln Mercury ★★★★★

Auto blog

Which is more fuel efficient, driving with a pickup's tailgate up or down?

Tue, 26 Aug 2014

Thanks to the smoke wand in the wind tunnel, you can actually see the difference in our video.

Should you drive with your pickup truck's tailgate up or down? It's an age-old controversy that's divided drivers for decades. Traditionalists will swear you should leave the tailgate down. Makes sense, right? It would seem to let the air flow more cleanly over the body and through the bed. But there's also a school of thought that argues trucks are designed to look and operate in a specific manner, and modern design techniques can help channel the airflow properly. So don't mess with all of that: Leave the tailgate up.

FCA, Ford idle plants due to semiconductor shortage

Fri, Jan 8 2021DETROIT (Reuters) - Ford and FCA will become the latest automakers to idle production facilities due to a semiconductor shortage. Ford's Louisville Assembly Plant in Kentucky will idle for a week, borrowing a down period from later in the year to compensate. Per Automotive News, FCA is idling its Brampton facility in Ontario, Canada, and one other site which has not yet been identified. Louisville Assembly is the production site for the Ford Escape and Lincoln Corsair SUVs; Brampton Assembly produces the Chrysler 300, Dodge Charger and Dodge Challenger for FCA. A Ford spokeswoman, who declined to identify the semiconductor supplier, confirmed the temporary shutdown to Reuters. In this, FCA and Ford join Nissan and potentially Honda in idling production in the wake of the shortage, which also hit Volkswagen late last year. The shortages are being blamed on consumer demand for silicon after production slowdowns resulting from the coronavirus pandemic. Volkswagen said it had to adjust production schedules in China, Europe and North America to compensate. Nissan said it planned to reduce production of the Note, a hybrid electric car, at its Oppama Plant in Kanagawa prefecture, Japan, but did not give details of the scale of the output cut. The Nikkei newspaper reported that Nissan would slash its Note production at Oppama to about 5,000 units in January, from an initially planned 15,000 units. "A global shortage of semiconductors has affected parts procurement in the auto sector. As a result of this shortage, the Oppama Plant in Japan will adjust production in January, reducing production of the Nissan NOTE," Nissan said in a statement. (This article contains reporting from Reuters.) Auto News Plants/Manufacturing UAW/Unions Chrysler Dodge Ford

Hot-selling Ford Expedition, Lincoln Navigator get production boost

Mon, Feb 12 2018Ford is investing an additional $25 million in its Kentucky Truck Plant in Louisville to increase by 25 percent production of the hot-selling and all-new Lincoln Navigator and Ford Expedition SUVs. The investment adds to $900 million in previously announced spending at the plant, which also builds F-Series Super-Duty pickups and employs 8,400 workers. Assembly-line workers are putting in overtime and working voluntary weekend shifts to keep up with demand. The new investment will cover upgrades to the assembly line but does not involve further hiring, Ford spokeswoman Kelli Felker says. The popularity of the Ford Expedition and Lincoln Navigator is a bright spot as Ford stock has been battered by Wall Street amid concerns concerns about the automaker's future vision and slowness to detect trends. Ford says the investment is an example of its bid to improve "operational fitness," one of CEO Jim Hackett's common refrains. Ford says Navigator retail sales more than doubled in January, and Navigators are spending an average of just seven days on Lincoln dealership lots as customers trade in vehicles including Land Rovers and Mercedes-Benz. Nearly 85 percent of buyers are opting for high-end Black Label and Reserve trim packages, contributing to an average transaction price increase of more than $21,000 in January compared to a year ago. The 2018 Navigator won the North American Truck of the Year award and also topped a Detroit News poll of public favorites at last month's Detroit Auto Show. Sales of the Expedition, meanwhile, were up almost 57 percent last month as the full-size SUVs also spent an average of just a week on dealer lots. Platinum trim models represented 29 percent of sales, pushing transaction price increases up $7,800. Ford gave the 2018 Expedition an all-aluminum body to save mass in its first significant redesign since 2007. The plant last year got nearly 400 new robots, mainly in the body shop, to help increase line speed, and Ford added a robot lab where employees can test software tweaks or troubleshoot issues away from the factory floor. The Louisville plant also benefits from extensive new data analytics, with seven big-screen monitors providing minute-by-minute updates showing progress against hourly targets or alerting workers to pending parts shortages. A huge spare-parts "vending machine" lets workers more quickly locate needed parts and keep inventory at necessary levels.