11 Ford Fiesta 4 Dooe Sedan Se, Power Windows & Locks on 2040-cars

Austin, Texas, United States

Transmission:Automatic

Body Type:Sedan

Vehicle Title:Clear

Fuel Type:GAS

Power Options: Air Conditioning, Power Locks, Power Windows

Make: Ford

Vehicle Inspection: Vehicle has been Inspected

Model: Fiesta

FuelType: Gasoline

Trim: SE Sedan 4-Door

Listing Type: Pre-Owned

Certification: None

Drive Type: FWD

Mileage: 30,533

BodyType: Sedan

Sub Model: 4dr Sdn SE

Cylinders: 4 - Cyl.

Exterior Color: Gray

DriveTrain: FRONT WHEEL DRIVE

Interior Color: Black

Number of Doors: 4 Generic Unit (Plural)

Warranty: Warranty

Number of Cylinders: 4

Safety Features: Anti-Lock Brakes, Side Airbags

Ford Fiesta for Sale

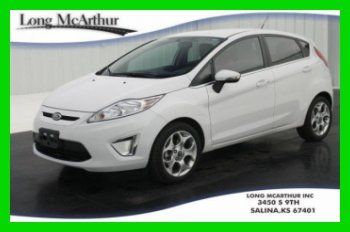

2011 ses 12k low miles heated leather microsoft sync! we finance and ship!(US $15,912.00)

2011 ses 12k low miles heated leather microsoft sync! we finance and ship!(US $15,912.00) 2012 ford fiesta 5dr hb se 2 keys power mirrors tire pressure monitor home link(US $13,480.00)

2012 ford fiesta 5dr hb se 2 keys power mirrors tire pressure monitor home link(US $13,480.00) We finance !! fiesta fun ! economic ! sporty !

We finance !! fiesta fun ! economic ! sporty ! Only 21k, automatic, pwr windows & locks, sync, alloys, 1-owner 12913(US $14,995.00)

Only 21k, automatic, pwr windows & locks, sync, alloys, 1-owner 12913(US $14,995.00) 2013 ford fiesta se sedan heated seats sync brand new!(US $14,905.00)

2013 ford fiesta se sedan heated seats sync brand new!(US $14,905.00) 2011 ford fiesta se - red candy metallic sedan(US $12,995.00)

2011 ford fiesta se - red candy metallic sedan(US $12,995.00)

Auto Services in Texas

WorldPac ★★★★★

VICTORY AUTO BODY ★★★★★

US 90 Motors ★★★★★

Unlimited PowerSports Inc ★★★★★

Twist`d Steel Paint and Body, LLC ★★★★★

Transco Transmission ★★★★★

Auto blog

Ford will keep Escape and MKC plant open an extra week to meet demand

Thu, Jun 8 2017Crossovers keep selling like popular pastries, and for Ford, that means it needs to keep production going. The company announced that, rather than the usual two-week shutdown, its Louisville, Ky., assembly plant will be open for one of those weeks. The plant builds the Ford Escape and Lincoln MKC, which Ford reports have had record sales. According to Ford, Escape sales through May are up 3 percent, and MKC sales are up 10 percent compared with last year. In total, the Escape has sold about 130,000 units through May, and the MKC has sold around 11,000. Keeping the Louisville plant open will allow the company to build an additional 8,500 vehicles. Ford stated that all other assembly plants will continue with the two-week shutdown as scheduled. Related Video: Featured Gallery 2017 Ford Escape: First Drive View 24 Photos Image Credit: Drew Phillips Plants/Manufacturing Ford Lincoln Crossover SUV Economy Cars Luxury lincoln mkc

UK's Loughborough University improving Ford's 1.0-litre EcoBoost engine

Wed, May 21 2014How much does it cost for college students to study zero emissions vehicles? At Loughborough University in the UK, a new Advanced Propulsion Centre (APC) is being built at a cost of a billion pounds ($1.7 billion US). The school has just announce that it will fund a number of grad student positions and is creating a new Chair in Advanced Propulsion Systems, which sounds like a fun job to us. We're weird like that. There will be a total of four professor-type positions in the new Center, including the chair, all focused on teaching students about low-carbon vehicle technologies, specifically electric and hybrid ones. The school is investing 1.5 million pounds ($2.5 million) for the new positions. There is a bigger picture as well, a 26-million pound ($44 million) Advanced Combustion Turbocharged Integrated Variable-valvetrain Engine (ACTIVE) project, which uses funds not only from the school but also from Ford and others. The point of ACTIVE is to study Ford's 1.0-liter EcoBoost engine and "improve further its efficiency and ensure it exceeds 2020 emission regulations." This is already a popular engine for the automaker, and it will need to stay at the bleeding edge of efficiency to remain as important in 2020 as it is today. Loughborough University has been working with automakers on advanced energy technologies for years, for example with Rolls-Royce and fuel cells in 2007 and the Lotus Hotfire engine in 2008. University invests GBP1.5M in advanced propulsion research to advance zero emissions vehicles challenge Loughborough University is investing GBP1.5M over five years in strategic research appointments, inspired by the global challenge to develop the new advanced propulsion technologies required for the move to zero emission vehicles. These appointments reinforce the University's world-class research in low-carbon vehicle technologies, adding new dimensions concerned with electric and hybrid drives. Four appointments will be made, including a Chair in Advanced Propulsion Systems, supported by a number of PhD studentships. The GBP1.5M investment is part of the University's commitment to the recently announced Advanced Propulsion Centre (APC) to support the development of new supply chains for low carbon vehicles. APC is an initiative established by the Automotive Council that will see GBP1 billion of investment from government and industry over the next 10 years.

Detroit automakers keep their masks on to keep the factories running

Tue, Oct 27 2020United Auto Workers members leave the Fiat Chrysler Automobiles Warren Truck Plant in May. Fiat Chrysler along with rivals Ford and General Motors Co., restarted the assembly lines after several weeks of coronavirus lockdown. (AP) ¬† DETROIT ó When the coronavirus pandemic slammed the United States in March, the Detroit Three automakers shut their plants and brought their North American vehicle production to an unprecedented cold stop. Now, four months after a slow and sometimes bumpy restart in May, many General Motors, Ford and Fiat Chrysler Automobiles¬† factories are working at close to full speed, chasing a stronger-than-expected recovery in sales. So far, none of the Detroit Three has had a major COVID-19 outbreak since restarting production, even as the coronavirus is surging in Midwestern and Southern communities outside factory walls. "We have people testing positive, but it's not affecting operations," said Ford global manufacturing chief Gary Johnson. Keeping the pandemic at bay has pushed the automakers and 156,000 U.S. factory employees represented by the United Auto Workers into unfamiliar work routines and extraordinary levels of cooperation among the rival automakers that will have to be sustained for months to come. For automakers, the automakers' COVID response has been as much about instilling new habits as relying on new technology. Workers log their symptoms, or lack of them, into smartphone apps and walk past temperature scanners to get to their work stations. But company and union executives said masks, along with physical distancing, are the key to keeping assembly lines rolling. "The mask is the foundation" of protecting workers on the job, said Johnson. Complaints about masks Autoworkers are accustomed to wearing protective gear such as shatterproof glasses and gloves. Masks that cover the mouth and nose, however, were not standard equipment on auto assembly lines, and were a tough sell at first. "The biggest complaint is wearing a mask," United Auto Workers President Rory Gamble told Reuters. "A lot of our members perform physical tasks. Wearing the mask inhibits breathing." Beyond that, Gamble said, masks and distancing make it harder for workers to have conversations on the job or socialize during breaks. "That¬ís pretty much out the window, and it makes for a longer day," he said. Masks make it harder for co-workers to read each other's expressions ¬ó often crucial in the noisy environment of a¬†car¬†plant.