1957 Ford Fairlane 500 on 2040-cars

South Amboy, New Jersey, United States

Body Type:2 DR

Engine:292 cu in

Vehicle Title:Clear

Fuel Type:Gasoline

For Sale By:Private Seller

Number of Cylinders: 8

Make: Ford

Model: Fairlane

Trim: Gold & Chrome

Warranty: Vehicle does NOT have an existing warranty

Drive Type: Auto Trans

Options: CD Player

Mileage: 60,000

Sub Model: 500

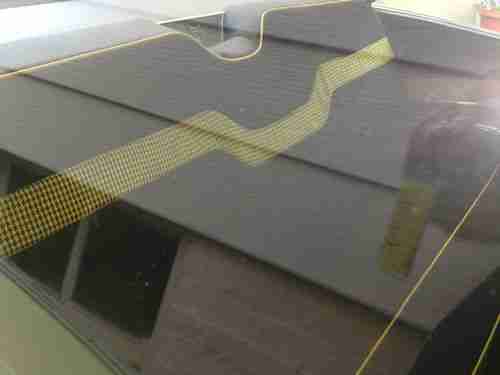

Exterior Color: Yellow & Black

Disability Equipped: No

Interior Color: Yellow & Black

Number of Doors: 2

Ford Fairlane for Sale

1964 ford fairlane 500 4-door 260cu v8(US $1,250.00)

1964 ford fairlane 500 4-door 260cu v8(US $1,250.00) 1966 ford fairlane 500 xl 2 dr hardtop(US $7,500.00)

1966 ford fairlane 500 xl 2 dr hardtop(US $7,500.00) Very rare 1958 ford fairlane 500 skyliner retractable hard top very nice !!

Very rare 1958 ford fairlane 500 skyliner retractable hard top very nice !! 1963 ford fairlane 500 3.6l(US $3,000.00)

1963 ford fairlane 500 3.6l(US $3,000.00) 1963 63 ford fairlane 500 4 door 260 c.i. v-8 cyl. automatic parts car

1963 63 ford fairlane 500 4 door 260 c.i. v-8 cyl. automatic parts car 1963 63 ford fairlane 500 4 door 200 c.i. in-line 6 cyl. automatic

1963 63 ford fairlane 500 4 door 200 c.i. in-line 6 cyl. automatic

Auto Services in New Jersey

World Jeep Chrysler Dodge Ram ★★★★★

VIP HONDA ★★★★★

Vespia`s Goodyear Tire & Svc ★★★★★

Tropic Window Tinting ★★★★★

Tittermary Auto Sales ★★★★★

Sparta Tire Distributors ★★★★★

Auto blog

How Ford switched gears for the all-new F-150

Fri, Mar 6 2015Editor's Note: This story is authored by Julia Halewicz, a senior editor with AOL's Custom Solutions Group. She holds a Masters in Journalism from NYU and has spent her career as an editor of various newspapers, magazines and digital outlets. Last year on the Friday before Labor Day, the 2014 Ford F-150 pickup truck came off the Dearborn assembly line for the last time. After the last seam was welded, the F-150 that had been so beloved by American consumers would begin the transition from traditional steel manufacturing to an aluminum body, and the second phase of Ford's 2007 blueprint for sustainability would begin. Jobs would be created, and Ford would deliver a stronger product to its consumers. It was a moment Ford would call the biggest in the company's 111-year history. Breaking The Mold For some, the change was almost unfathomable. How could a truck be made with aluminum, and why change what clearly was working very well for the company? "We have a saying at Ford that leaders lead," said Doug Scott, the company's truck group marketing manager. "This was an ideal product to make with aluminum-alloy, because lightweighting made so much sense for a truck, because the extent to which you could take weight out of a truck, you could add more value to the customer in terms of more towing, more payload, more durability, more efficiency – so again all this required us to be out in front further out in front that we normally would be to make sure that we would deliver on all those expectations." Ford began the planning process about five years before the first aluminum F-150 would come to market. The company had a lot of questions. What was customer acceptance of aluminum, could they build the truck, and could the truck be repaired out in the field? Finally, Ford needed to determine if there were enough materials available to support the demand for the F-Series. Aluminum vehicles aren't unusual, but had never been built on the scale of the F-150 – approximately one every minute. Ford created two prototypes to determine if the product would meet and exceed consumer expectations. Any change to the vehicle had to be justified in performance, safety and economy. An aluminum truck needed to be safer, lighter, have increased payload, haul more, and have improved fuel efficiency. After driving the prototypes, Ford knew it was ready to move forward. Once the aluminum truck was ready to build, the next challenge was quickly transforming the plant.

A cool boost to turbocharger performance

Fri, Jul 17 2015Since the advent of the forced-induction engine, we have been looking for ways to get every drop of performance we can. There are many approaches to getting additional power using better intercooling, water injection, or even adding nitrous oxide. One take on a short instant burst of power is being researched by Mahle and involves providing supercooled air to an engine, which allows it to burn a leaner fuel mixture and produce more power. The supercooling idea is not new and was examined by Ford in 1993 on the Mustang Mach III concept car, then brought up again in 2003 with the SVT F-150 Lightning concept. Ford called its system the SuperCooler; it was designed to work with any turbocharged or supercharged engine equipped with a water-to-air intercooler. The system on the Lightning concept used a small tank of antifreeze that was hooked up to the truck air conditioning compressor. The air conditioning compressor cooled the antifreeze down to about 30 degrees. The other side of the tank was hooked up to the air-to-water intercooler, which usually had a temperature over 100 degrees. Once the antifreeze was circulated from the tank into the intercooler, it would lower the intercooler temperature and provide for a cooler, denser air charge into the engine; the result was around 50 extra horsepower for a burst of about 30 seconds to a minute, depending on the size of the tank. The system for the Lightning was to be offered as a $750 option and would have been targeted towards drag racers and the like, as it could be used for a run down the drag strip and then re-cooled by the time the truck was back in line. The system was fairly non-intrusive – it only weighed about 25 pounds and did not require a new compressor or intercooler. But as with many concepts, it was ultimately scrapped. The technology was always stuck in the back of my mind, but with larger and more powerful engines being produced it could not find its place. With the advent of new fuel economy standards, we have seen small-displacement turbocharged engines pop up and they seem like the perfect candidate for this type of technology. Ford's EcoBoost 1.0-liter three-cylinder turbocharged engine, as used in the Fiesta and Focus, is one such candidate for this technology. It would add a negligent amount of weight but could provide a boost of 10 to 20 horsepower when needed, like merging onto the highway or catching up to traffic.

Aluminum Ford F-150 earns five-star crash rating [w/video]

Thu, Apr 16 2015The scores are in, and the 2015 Ford F-150 has been awarded a five-star Overall Vehicle Score in the National Highway Traffic Safety Administration's testing. That makes it, according to Ford, the safest F-150 ever. "The five-star safety rating is a terrific example of One Ford collaboration and innovation," Vice President of Global Product Development Raj Nair said in a statement. "Our truck team worked together for years to deliver this accomplishment, using an unprecedented combination of advanced materials throughout the all-new F-150. The 2015 model is engineered to be the safest F-150 ever, which matters to customers who depend on this truck to not only get the job done, but also get them safely home." The new F-150's aluminum and high-strength-steel construction posed some unique challenges to truck's engineers. "The team had to invent new ways to manage crash energy, because advanced materials like high-strength steel behave differently," Matt Niesluchowski, the truck's safety manager. "We found that changing certain shapes led to a weight reduction, while also improving crash performance." Beyond the structural safety features, the 2015 F-150 is loaded with additional safety features, including an adaptive steering column and Ford's inflatable seat belts, that protects drivers in the event of a collision. Beyond that, there's the usual array of active safety features meant to prevent a crash in the first place, including Curve Control and forward collision warning with brake support. Check out Ford's full press release on its five-star score, as well as video on the truck's safety features.