2006 Ford F-250 Lifted Super Duty Xl Crew Cab Pickup 4-door 6.0l on 2040-cars

Debary, Florida, United States

Body Type:Crew Cab Pickup

Engine:6.0L 363Cu. In. V8 DIESEL OHV Turbocharged

Vehicle Title:Clear

Fuel Type:Diesel

For Sale By:Private Seller

Number of Cylinders: 8

Make: Ford

Model: F-250 Super Duty

Trim: XL Crew Cab Pickup 4-Door

Warranty: Vehicle does NOT have an existing warranty

Drive Type: 4WD

Options: 4-Wheel Drive, CD Player

Mileage: 102,300

Safety Features: Driver Airbag, Passenger Airbag

Sub Model: FX4

Power Options: Air Conditioning, Cruise Control, Power Locks, Power Windows, Power Seats

Exterior Color: Black

Interior Color: Gray

2006 FORD F250 HAS A 10"IN PRO-COMP LIFT ON 38"IN TOYOS. 5 INCH EXHAUST KENWOOD SYSTEM AMP AND BOX GREAT TRUCK REAL HEAD TURNER SHARP TRUCK

Ford F-250 for Sale

1997 ford f-250 heavy duty 4x4 pickup snowplow garage kept clean low miles nice

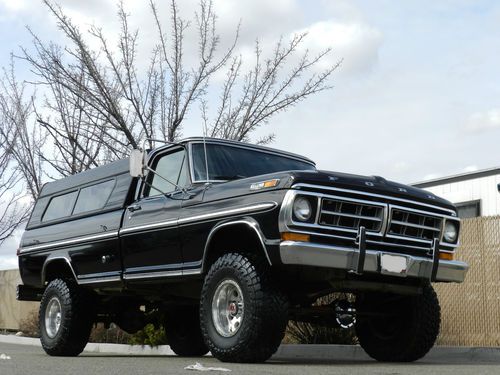

1997 ford f-250 heavy duty 4x4 pickup snowplow garage kept clean low miles nice 1972 ford highboy ranger 4x4 94k miles, collector , 60+pics black on black

1972 ford highboy ranger 4x4 94k miles, collector , 60+pics black on black One-owner!! ford superduty crew cab fx4 4x4 powerstroke diesel(US $20,995.00)

One-owner!! ford superduty crew cab fx4 4x4 powerstroke diesel(US $20,995.00) 2008 ford f-250 super duty king ranch crew cab pickup 4-door 6.4l no reserve

2008 ford f-250 super duty king ranch crew cab pickup 4-door 6.4l no reserve 2008 ford f250 harler-davidson 4x4 sunroof nav rear cam texas direct auto(US $38,980.00)

2008 ford f250 harler-davidson 4x4 sunroof nav rear cam texas direct auto(US $38,980.00) 2006 ford f-250 super duty xlt crew cab pickup 4-door 6.0l(US $12,500.00)

2006 ford f-250 super duty xlt crew cab pickup 4-door 6.0l(US $12,500.00)

Auto Services in Florida

Zacco`s Import car services ★★★★★

Y & F Auto Repair Specialists ★★★★★

Xtreme Auto Upholstery ★★★★★

X-Treme Auto Collision Inc ★★★★★

Velocity Window Tinting ★★★★★

Value Tire & Alignment ★★★★★

Auto blog

Consumer Reports explains its disdain for infotainment

Thu, 20 Mar 2014One of the perks of reviewing all manner of cars and trucks is that we're exposed to all the different infotainment systems. Whether Cadillac's CUE, Chrysler's UConnect, BMW's iDrive or MyFord Touch, we sample each and every infotainment system on the market.

Not surprisingly, some are better than others. It seems consumers have come to a similar consensus, with Consumer Reports claiming that Ford and Lincoln, Cadillac and Honda offer the worst user infotainment experiences. Not surprisingly, you won't find much argument among the Autoblog staff.

Take a look below to see just what it is about the latest batch of infotainment systems that grinds CR's gears. After that, scroll down into Comments and let us know if you agree with the mag's views.

2014 Ford F-150 gets CNG option

Wed, 31 Jul 2013Ford is toiling away, installing heavy-duty engine components into select 3.7-liter V6s to allow them to run on compressed natural gas (CNG) and liquid petroleum gas (LPG) in addition to gasoline. That's nothing new, but now, Ford has announced that it will offer the 2014 F-150 with this engine configuration, bringing the Blue Oval's total number of CNG/LPG-friendly vehicles up to eight. The F-150 will be the only half-ton pickup on the market that can run on these gases.

Ford will charge $315 per vehicle to equip the optional engine, but the trucks won't be ready to run on the alternative fuels straight from the factory and must be upfitted with additional equipment. A Ford Qualified Vehicle Modifier will install a separate fuel system for the compressed gases at a cost of $7,500 to $9,500, depending on fuel tank size. With the right-size tank, the F-150 equipped with the CNG/LPG-prepped engine can go 750 miles on one tank of gas, according to Ford, averaging 23 miles per gallon.

The practice of offering flex-fuel vehicles is gaining momentum as businesses take advantage of cheap gas. CNG can be bought for $2.11/gallon on average (per gasoline equivalent), and sometimes for as little as $1.00 in some parts of the US, Ford states. "With the money saved using CNG, customers could start to see payback on their investment in as little as 24 to 36 months," says Jon Coleman, Ford's fleet sustainability and technology manager. The automaker expects to sell a total of 15,000 CNG/LPG-prepped vehicles in the 2014 model year.

For EV drivers, realities may dampen the electric elation

Mon, Feb 20 2023The Atlantic, a decades-old monthly journal well-regarded for its intelligent essays on international news, American politics and cultural happenings, recently turned its attention to the car world. A piece that ran in The Atlantic in October examined the excesses of the GMC Hummer EV for compromising safety. And now in its latest edition, the magazine ran a compelling story about the challenges of driving an electric vehicle and how those experiences “mythologize the car as the great equalizer.” Titled “The Inconvenient Truth About Electric Vehicles,” the story addresses the economics of EVs, the stresses related to range anxiety, the social effects of owning an electric car — as in, affording one — and the overarching need for places to recharge that car. Basically, author Andrew Moseman says that EV life isn't so rosy: “On the eve of the long-promised electric-vehicle revolution, the myth is due for an update. Americans who take the plunge and buy their first EV will find a lot to love Â… they may also find that electric-vehicle ownership upends notions about driving, cost, and freedom, including how much car your money can buy. "No one spends an extra $5,000 to get a bigger gas tank in a Honda Civic, but with an EV, economic status is suddenly more connected to how much of the world you get to see — and how stressed out or annoyed youÂ’ll feel along the way.” Moseman charts how a basic Ford F-150 Lightning electric truck might start at $55,000, but an extended-range battery, which stretches the distance on a charge from 230 miles to 320, “raises the cost to at least $80,000. The trend holds true with all-electric brands such as Tesla, Rivian, and Lucid, and for many electric offerings from legacy automakers. The bigger battery option can add a four- or five-figure bump to an already accelerating sticker price.” As for the charging issue, the author details his anxiety driving a Telsa in Death Valley, with no charging stations in sight. “For those who never leave the comfort of the city, these concerns sound negligible," he says. "But so many of us want our cars to do everything, go everywhere, ferry us to the boundless life we imagine (or the one weÂ’re promised in car commercials),” he writes. His conclusions may raise some hackles among those of us who value automotive independence — not to mention fun — over practicalities.