2005 Chrysler Crossfire Limited on 2040-cars

Arnold, Missouri, United States

Transmission:Manual

Fuel Type:Gasoline

For Sale By:Private Seller

Vehicle Title:Clean

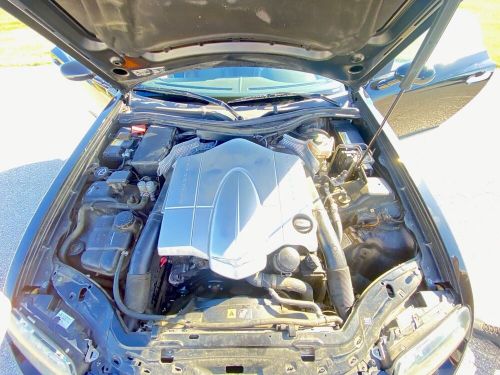

Engine:3.2L Gas V6

VIN (Vehicle Identification Number): 1C3AN65L95X040026

Mileage: 50000

Trim: LIMITED

Number of Cylinders: 6

Make: Chrysler

Drive Type: RWD

Model: Crossfire

Exterior Color: Black

Chrysler Crossfire for Sale

2005 chrysler crossfire limited 2dr roadster(US $19,500.00)

2005 chrysler crossfire limited 2dr roadster(US $19,500.00) 2005 chrysler crossfire leather two tone(US $12,000.00)

2005 chrysler crossfire leather two tone(US $12,000.00) 2004 chrysler crossfire(US $8,900.00)

2004 chrysler crossfire(US $8,900.00) 2007 chrysler crossfire roadster 6spd manual(US $19,995.00)

2007 chrysler crossfire roadster 6spd manual(US $19,995.00) 2005 chrysler crossfire limited(US $8,900.00)

2005 chrysler crossfire limited(US $8,900.00) 2005 chrysler crossfire(US $9,000.00)

2005 chrysler crossfire(US $9,000.00)

Auto Services in Missouri

Wyatt`s Garage ★★★★★

Woodlawn Tire & Auto Center ★★★★★

West County Auto Body Repair ★★★★★

Tiger Towing ★★★★★

Straatmann Toyota ★★★★★

Scott`s Auto Repair ★★★★★

Auto blog

Auto News Recap For 5.13.16 | Autoblog Minute

Fri, May 13 2016Senior Editor Greg Migliore recaps the week in automotive news, including a look at Hyperloop One's desert propulsion test, Chrysler 300 rumors, and Nissan's purchase of Mitsubishi. Chrysler Mitsubishi Nissan Autoblog Minute Videos Original Video hyperloop

FCA, Ford idle plants due to semiconductor shortage

Fri, Jan 8 2021DETROIT (Reuters) - Ford and FCA will become the latest automakers to idle production facilities due to a semiconductor shortage. Ford's Louisville Assembly Plant in Kentucky will idle for a week, borrowing a down period from later in the year to compensate. Per Automotive News, FCA is idling its Brampton facility in Ontario, Canada, and one other site which has not yet been identified. Louisville Assembly is the production site for the Ford Escape and Lincoln Corsair SUVs; Brampton Assembly produces the Chrysler 300, Dodge Charger and Dodge Challenger for FCA. A Ford spokeswoman, who declined to identify the semiconductor supplier, confirmed the temporary shutdown to Reuters. In this, FCA and Ford join Nissan and potentially Honda in idling production in the wake of the shortage, which also hit Volkswagen late last year. The shortages are being blamed on consumer demand for silicon after production slowdowns resulting from the coronavirus pandemic. Volkswagen said it had to adjust production schedules in China, Europe and North America to compensate. Nissan said it planned to reduce production of the Note, a hybrid electric car, at its Oppama Plant in Kanagawa prefecture, Japan, but did not give details of the scale of the output cut. The Nikkei newspaper reported that Nissan would slash its Note production at Oppama to about 5,000 units in January, from an initially planned 15,000 units. "A global shortage of semiconductors has affected parts procurement in the auto sector. As a result of this shortage, the Oppama Plant in Japan will adjust production in January, reducing production of the Nissan NOTE," Nissan said in a statement. (This article contains reporting from Reuters.) Auto News Plants/Manufacturing UAW/Unions Chrysler Dodge Ford

Stellantis invests more than $100 million in California lithium project

Thu, Aug 17 2023Stellantis said it would invest more than $100 million in California's Controlled Thermal Resources, its latest bet on the direct lithium extraction (DLE) sector amid the global hunt for new sources of the electric vehicle battery metal. The investment by the Chrysler and Jeep parent announced on Thursday comes as the green energy transition and U.S. Inflation Reduction Act have fueled concerns that supplies of lithium and other materials may fall short of strong demand forecasts. DLE technologies vary, but each aims to mechanically filter lithium from salty brine deposits and thus avoid the need for open pit mines or large evaporation ponds, the two most common but environmentally challenging ways to extract the battery metal. Stellantis, which has said half of its fleet will be electric by 2030, also agreed to nearly triple the amount of lithium it will buy from Controlled Thermal, boosting a previous order to 65,000 metric tons annually for at least 10 years, starting in 2027. "This is a significant investment and goes a long way toward developing this key project," Controlled Thermal CEO Rod Colwell said in an interview. The company plans to spend more than $1 billion to separate lithium from superhot geothermal brines extracted from beneath California's Salton Sea after flashing steam off those brines to spin turbines that will produce electricity starting next year. That renewable power is expected to cut the amount of carbon emitted during lithium production. Rival Berkshire Hathaway has struggled to produce lithium from the same area given large concentrations of silica in the brine that can form glass when cooled, clogging pipes. Colwell said a $65 million facility recently installed by Controlled Thermal can remove that silica and other unwanted metals. DLE equipment licensed from Koch Industries would then remove the lithium. "We're very happy with the equipment," he said. "We're going to deliver. There's just no doubt about it." Stellantis CEO Carlos Tavares called the Controlled Thermal partnership "an important step in our care for our customers and our planet as we work to provide clean, safe and affordable mobility." Both companies declined to provide the specific investment amount. Controlled Thermal aims to obtain final permits by October and start construction of a commercial lithium plant soon thereafter, Colwell said. Goldman Sachs is leading the search for additional debt and equity financing, he added.