Chevrolet Other Pickups Kodiak, C4500 on 2040-cars

Littlerock, California, United States

This one of a kind former show truck can be yours today. This truck has been on the cover of two different magazines, and turns heads everywhere! Truck is CA street legal, no short cuts were taking when I built this truck. Show, tow or go, this truck can do it all!! Truck runs strong, lots of power, easy to drive. No blind spots thanks to camera system in front fenders.

Chevrolet Other Pickups for Sale

Chevrolet other custom bomber rat rod(US $10,000.00)

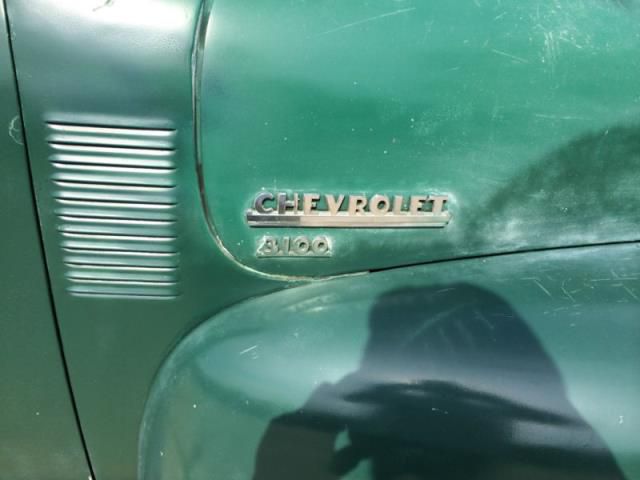

Chevrolet other custom bomber rat rod(US $10,000.00) Chevrolet other pickups chevy 3100(US $7,000.00)

Chevrolet other pickups chevy 3100(US $7,000.00) Chevrolet other standard(US $10,000.00)

Chevrolet other standard(US $10,000.00) 1932 - chevrolet other(US $13,000.00)

1932 - chevrolet other(US $13,000.00) Chevrolet other z28(US $7,000.00)

Chevrolet other z28(US $7,000.00) 1957 - chevrolet other pickups(US $1,000.00)

1957 - chevrolet other pickups(US $1,000.00)

Auto Services in California

Yuba City Toyota Lincoln-Mercury ★★★★★

World Auto Body Inc ★★★★★

Wilson Way Glass ★★★★★

Willie`s Tires & Alignment ★★★★★

Wholesale Import Parts ★★★★★

Wheel Works ★★★★★

Auto blog

GMC Canyon, Chevy Colorado diesels finally heading to dealers

Fri, Jan 1 2016Customers who have been waiting to receive their diesel-powered Chevrolet Colorados and GMC Canyons should be relived to hear that GM will finally start to ship them out of the Wentzville Assembly Plant. "The highly anticipated 2016 GMC Canyon diesel has begun shipping to dealers," a company spokesperson confirmed to The Detroit News. The trucks originally had a fall launch date, but a final review forced a delay in deliveries. The 2.8-liter four-cylinder diesel in the midsize trucks produces 181 horsepower and 369 pound-feet of torque, and the company touts the engine's low emissions. The Environmental Protection Agency and California Air Resources Board even put the mill through extra scrutiny with a real world test in the wake of VW's diesel scandal, and the Duramax passed with no problems. At that time, a Chevy spokesperson told Autoblog that the models' launch was on track. The Duramax engine adds $3,730 to the price of a comparable V6 model, but they're the most fuel-efficient pickups on the market. The EPA estimates the twins at 31 miles per gallon highway, 22 mpg city, and 25 mpg combined in two-wheel drive form and 29/20/23 with four-wheel drive. Buyers likely can't wait to finally experience these pickups after reading a heap of positive reviews. The Colorado diesel recently earned Motor Trend's Truck of the Year award. We also came away impressed with it during our First Drive and liked the Canyon during our Quick Spin. Related Video:

Recharge Wrap-Up: LAPD gets Zero MMX, Chevy's new inverter, Hyundai Tucson's new powertrains

Wed, Jul 16 2014Some police in Los Angeles will be riding Zero MMX electric motorcycles on duty. The LAPD is adding the fully electric police/military all-terrain bikes to its patrol fleet. According to Officer Steve Carbajal of the department's off-road unit, "It costs less than 50 cents to charge compared to using gallons of gas, maintenance is simple, and the community appreciates how quiet they are." The electric bikes, with their lack of noise and a headlight the rider can turn off, also have the benefit of stealth, giving the officers what Carbajal calls "an added tactical advantage." The MMX also has swappable batteries, is designed for quick ignition and has power reserve capabilities so the rider won't be caught with a dead battery while chasing down a perp. Read more at Ride Apart. Remember when it seemed like we'd never run out of oil, and giving your buddy five bucks for gas was actually a worthwhile gesture? Drivers of classic cars in Detroit were able to fill up their tanks at gas prices corresponding to their model year, thanks to a promotion by Hagerty Insurance for National Collector Car Appreciation Day on July 11. That meant prices from 21 to 90 cents a gallon, as the cars that showed up ranged from the years 1929 to 1989. That's about as affordable as charging your EV. Head over to Autoweek for more details and some photos from the event. The next-generation Chevrolet Volt will likely benefit from a new inverter being developed by General Motors. GM is about two-thirds of the way through the development of the new inverter, which should be ready in January 2016. The inverter, which has a peak output of 55 kilowatts a continuous output of 33 kilowatts, will be adaptable for use in other GM vehicles. Chevrolet is working to reduce the Volt's production costs by $10,000 per vehicle, which should make it more affordable, and the new inverter could help reach that goal should it make its way into the car. Read more at Green Car Reports. Hyundai is likely planning some interesting powertrain changes for the 2016 Tucson, says Green Car Reports. Plug-in hybrid? Maybe. Diesel? Probably not. "We are covering the waterfront on all alternative fuel strategies, from standard hybrid, to plug-in, battery-electric, and fuel cell," says Hyundai's US Chief Dave Zuchowski.

Did the Chevy Corvette Z06 break 7 minutes at the Ring? Not likely

Wed, Jan 28 2015"Just because it's on the internet doesn't make it true." That's rule number one, two and arguably, three, of surfing the world wide web. In today's example of this rule, we have the following. The website HorsepowerKings is claiming that a 2015 Chevrolet Corvette Z06, with the eight-speed automatic and Z07 package, managed to lap the Nurburgring Nordschleife in under seven minutes. To put that in perspective, that super-quick time would put the 650-horsepower, $97,000 (the price of a 2LZ with the Z07/8AT combo) Z06 a mere two seconds slower around the world's most challenging race track than the $929,000, 887-horsepower Porsche 918 Spyder Weissach. It's about eight seconds quicker than Nissan's own test of the GT-R Nismo Track Pack and 13 seconds faster than a Dodge Viper ACR. Unfortunately, Chevy says there isn't anything to it. We reached out to the Bowtie's Monte Doran, who confirmed that HK's claims are "not accurate." "Any one – a manufacturer, a journalist, a guy standing on the fence of the Ring – can claim a lap time. As such, we think the in-car video is essential to proving a time is real and credible, and Chevrolet will not release a lap until we have a video to substantiate the claim," Doran told Autoblog. "Chevrolet accumulated nearly 1,000 miles of testing on the Nurburgring with the Z06. During that time, we only had two opportunities to run a lap on video – and both were rained out. If we get a lap on video, we will post an official time." Doran finished by referencing the "only official lap time" for the Z06 – a 2:41 around the Virginia International Raceway. Frankly, we aren't terribly surprised by Chevy's position. One would imagine if the Z06 were matching million-dollar hypercars around the 'Ring, the company would literally be screaming about it from Renaissance Center's rooftop. As this is quite the opposite of that, though, we're betting that the real Z06 lap time - while still likely very, very fast – won't be quite quick enough to frighten the brightest and best of today's hypercars.