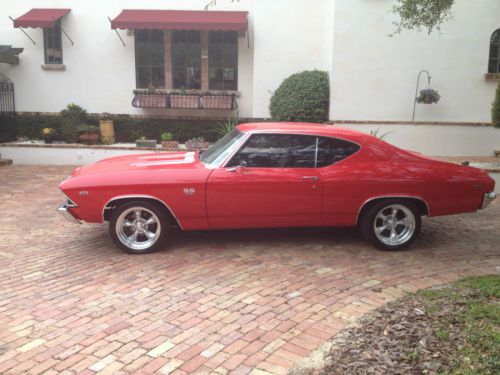

1969 396 Ss Chevelle 4 Speed on 2040-cars

Tampa, Florida, United States

|

1969 SS Chevelle 396 4speed , this car is a complete frame off restoration with all information and records.

|

Chevrolet Chevelle for Sale

** survivor car * 100% original paint * #s matching **(US $54,950.00)

** survivor car * 100% original paint * #s matching **(US $54,950.00) 1968 chevrolet chevelle ss396, true 138 vin, multiple car show winner!!

1968 chevrolet chevelle ss396, true 138 vin, multiple car show winner!! 1970 chevrolet chevelle big block 63k original miles(US $22,500.00)

1970 chevrolet chevelle big block 63k original miles(US $22,500.00) 1968 chevelle malibu sport coupe with 327 engine & th-350 trans(US $15,200.00)

1968 chevelle malibu sport coupe with 327 engine & th-350 trans(US $15,200.00) 67 chevelle 138 ss 4sp new 406 sbc(US $17,500.00)

67 chevelle 138 ss 4sp new 406 sbc(US $17,500.00) 1969 chevelle malibu convertible

1969 chevelle malibu convertible

Auto Services in Florida

Zeigler Transmissions ★★★★★

Youngs Auto Rep Air ★★★★★

Wright Doug ★★★★★

Whitestone Auto Sales ★★★★★

Wales Garage Corp. ★★★★★

Valvoline Instant Oil Change ★★★★★

Auto blog

GM patent reveals new two-stage turbocharger

Fri, Jun 24 2016Modern turbochargers may be some of the best ever made, but performance is something that engineers are always trying to improve. According to GM Inside News, General Motors (GM) is hoping to alleviate some of the negative aspects of a two-stage turbocharger setup with a newly-patented design. The patent, that was filed on May 19, 2016, reveals a clever bypass system that allows the engine, a four-cylinder unit, to optimize both the low-pressure and high-pressure inlets for its respective functions. According to the filing, a conventional two-stage turbocharger setup is engineered to allow both turbines to operate simultaneously at low and mid engine speeds. At high engine speeds, only the low-pressure turbine works. The setup can't isolate either the low or high pressure side, which can impair low-end performance. GM's new two-stage turbocharger setup looks to eliminate this by linking the high-pressure turbo to the exhaust manifold through the high-pressure inlet duct. The low-pressure turbo is attached to the high-pressure turbo by a low-pressure inlet duct, which is linked to a connecting channel. A single actuator that is housed in the exhaust manifold creates a bypass that can opens the high-pressure inlet or close the connecting channel. Depending on what the engine load and speed is, the ECU guides the actuator—a single rotating spindle with discs corresponding to flanges on the high and low pressure sides—to isolate one of the two turbos. Isolating the turbos allow the respective inlets to be engineered for the best possible fluid dynamic performance. The setup should increase performance and decrease lag. There's no word on what car this setup will make an appearance on, but it will most likely be used in premium vehicles before trickling down to the rest of GM's vehicles. Related Video: News Source: GM Inside News, AutoGuide via GM Authority Cadillac Chevrolet GM Technology Sedan turbo patent engine turbocharging

Millionth Corvette now being restored after sinkhole damage

Thu, Jun 11 2015Among the original American sports cars that were damaged by the sinkhole at the National Corvette Museum over a year ago was a 1992 convertible that was the millionth Vette made. And now that milestone vehicle is starting its restoration process. The landmark Corvette's rehabilitation is being carried out by the GM Design Center in Warren, MI, by a team of skilled craftsmen and technicians. The crew is more accustomed to building prototypes and concepts, but will face a new challenge in bringing this millionth Corvette back to its original condition. The white-over-red convertible was one of eight Corvettes that were swallowed up by the sinkhole at the museum in Bowling Green early in the morning on February 12, 2014. Five will be preserved in their compromised condition as part of a display demonstrating the effects of the sinkhole, while the remaining three were earmarked for restoration. The Design Center team has already completely the restoration of the 2009 Corvette ZR1 "Blue Devil" prototype, while the remaining 1962 Corvette will be restored by the museum. Related Video: Sinkhole-Swallowed 1 Millionth Corvette Restoration Underway Milestone damaged when earth opened beneath National Corvette Museum 2015-06-10 WARREN, Mich. – Craftspeople and technicians at the General Motors Design Center are painstakingly restoring the historic 1 millionth Chevrolet Corvette damaged nearly 16 months ago when a sinkhole opened beneath the National Corvette Museum in Bowling Green, Ky. The restoration crew is part of GM's Mechanical Assembly group at the Design Center, which typically spends its time building prototype and concept vehicles. The white 1992 Corvette is a challenge because rather than build an all-new vehicle from the ground up, the workers are trying to preserve the original appearance of a production vehicle. It is the second of three sinkhole-damaged Corvettes that Chevrolet has pledged to restore. The first, a 2009 Corvette ZR1 prototype known as the Blue Devil, was only lightly damaged and was returned to its original condition last fall. The National Corvette Museum will oversee the restoration of the third car, a 1962 Corvette. Five other Corvettes swallowed by the sinkhole will remain in their as-recovered state to preserve the historical significance of the cars. They will become part of a future sinkhole-themed display at the museum. Sinkhole summary On Wednesday, Feb.

Why an independent rear suspension for GM's new, full-sized SUVs wasn't easy

Mon, Dec 23 2019A Motor Trend report last month laid out how Cadillac's 4.2-lier twin-turbo Blackwing V8 could be an orphan due to cost concerns in the GM empire. Last-minute chassis changes to Cadillac's new sedans and XT6 crossover led to engine bays that couldn't fit the Blackwing. On the SUV side, according to the report, the new independent rear suspension for big people haulers cost so much to implement that GM ruled out reworking the Escalade to accept the Blackwing. At least one commenter rightly asked how could a suspension swallow that much money. A new piece in Motor Trend has the answer. The excellent Alissa Priddle spoke to Tim Herrick, GM's executive chief engineer for full-size trucks, about why the clean-sheet IRS cost "multimillions of dollars."Â First, GM would need to build a new body shop at the Arlington, Texas plant that assembles the automaker's big SUVs to stamp the numerous wholly new parts and panels accommodating an IRS. Then GM would need to design and pay for a new assembly process. On top of those up-front costs, there was the incremental cost of the four-link IRS components being more expensive than those in the trucks' former leaf-sprung solid axles. Herrick endured so many rejections for so long that he remembers the date and time when he got approval for the new unit. He said it came down to a meeting where he told a higher-up, "I'll make you a deal: If we get to the reveal, or if we launch this and you think this was a dumb idea, I'll hand you my badge and let you walk me out." Head to Motor Trend to read the full story. Based on Herrick being on stage to help present the new SUVs to the press, and on our First Ride in the new Chevrolet Tahoe and Suburban at GM's Milford Proving Grounds, it appears this will have a happy ending for all involved. Furthermore, since Herrick worked on the T1 platform that supports the big SUVs as well as the light- and heavy-duty pickups, he understood the demands on the commercial side, too. That could be why when Roadshow asked Tim Asoklis, chief engineer of the Tahoe and Suburban, if the new IRS could endure life in the Chevrolet Silverado and GMC Sierra, Asoklis answered, "Oh, absolutely." Related Video: Â Â