1966 - Chevrolet Chevelle Ss on 2040-cars

Oakville, California, United States

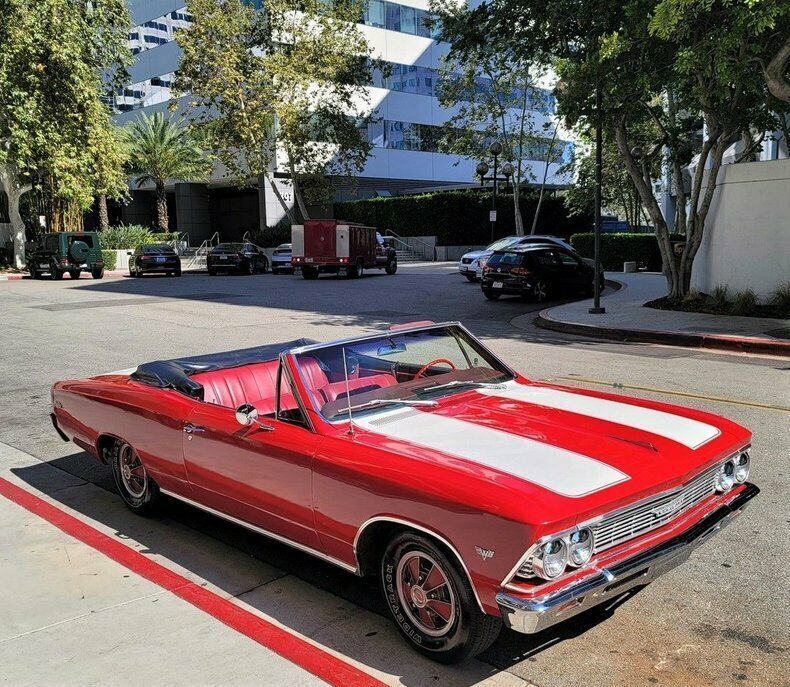

1966 Chevy Chevelle SS 396 C.I. V8 Tremec Manual 6 Speed A/C Restored!

Chevrolet Chevelle for Sale

1970 chevrolet chevelle(US $16,800.00)

1970 chevrolet chevelle(US $16,800.00) 1970 chevrolet chevelle ss(US $17,360.00)

1970 chevrolet chevelle ss(US $17,360.00) 1969 chevrolet chevelle ss ss(US $15,820.00)

1969 chevrolet chevelle ss ss(US $15,820.00) 1965 chevrolet chevelle malibu(US $20,650.00)

1965 chevrolet chevelle malibu(US $20,650.00) 1970 chevrolet chevelle restomod(US $15,400.00)

1970 chevrolet chevelle restomod(US $15,400.00) 1966 chevrolet chevelle restored 1966 chevrolet chevelle malibu(US $17,500.00)

1966 chevrolet chevelle restored 1966 chevrolet chevelle malibu(US $17,500.00)

Auto Services in California

Zip Auto Glass Repair ★★★★★

Z D Motorsports ★★★★★

Young Automotive ★★★★★

XACT WINDOW TINTING & 3M CLEAR BRA PAINT PROTECTION ★★★★★

Woodland Hills Honda ★★★★★

West Valley Machine Shop ★★★★★

Auto blog

Dale Earnhardt, Jr. puts his Callaway Corvette and '55 Chevy on eBay

Sat, Jan 24 2015Dale Earnhardt, Jr. has put a couple of his personal cars up for sale on eBay. The first is a 1955 Chevy Bel Air that Junior had reworked by Funkmaster Flex, a bit of a diversion from Flex's more common Ford efforts. Junior's ride has a replacement chassis from Jim Meyer Racing, a 434 small-block tuned by Sharioff Racing to 500 horsepower, and truly thin rubber on what appear to be aluminum billet rims with Junior's former number 8 on the center caps. The interior is all custom and painted to match the outside, and those seats have been completely reupholstered. The second car is a 1999 Callaway C12, the 18th of 19 C12s built that year and featured in a 2002 issue of AutoWeek. It joined Earnhardt's private collection in 2004. Built on the base of a C5 Chevrolet Corvette and using a lot of technical know-how from Callaway's European racing program, the BMW #287 Blue Pearl C12 had its V8 bored out to 6.2 liters and graced with Callaway's Supernatural upgrade; it also has a Callaway coil-over suspension with adjustable dampers. There's new bodywork all around, and when new it cost about $200,000. At the time of writing bidding on the Bel Air was up to $80,100, the C12 was at $63,100. The auction ends Monday morning, and the winning bidders have the option of having their prizes autographed and retrieving the keys from Dale Jr himself if they're willing to go to Moorseville, NC. Featured Gallery Dale Earnhardt Jr. '55 Chevy Bel-Air View 28 Photos Related Gallery Dale Earnhardt Jr. Callaway C12 View 24 Photos News Source: Dale Earnhardt Jr via eBay [1], [2] Aftermarket Celebrities Chevrolet Auctions Coupe Luxury Special and Limited Editions Performance Classics eBay callaway callaway corvette Chevy Bel Air

Is the skill of rev matching being lost to computers?

Fri, Oct 9 2015If the ability to drive a vehicle equipped with a manual gearbox is becoming a lost art, then the skill of being able to match revs on downshifts is the stuff they would teach at the automotive equivalent of the Shaolin Temple. The usefulness of rev matching in street driving is limited most of the time – aside from sounding cool and impressing your friends. But out on a race track or the occasional fast, windy road, its benefits are abundantly clear. While in motion, the engine speed and wheel speed of a vehicle with a manual transmission are kept in sync when the clutch is engaged (i.e. when the clutch pedal is not being pressed down). However, when changing gear, that mechanical link is severed briefly, and the synchronization between the motor and wheels is broken. When upshifting during acceleration, this isn't much of an issue, as there's typically not a huge disparity between engine speed and wheel speed as a car accelerates. Rev-matching downshifts is the stuff they would teach at the automotive equivalent of the Shaolin Temple. But when slowing down and downshifting – as you might do when approaching a corner at a high rate of speed – that gap of time caused by the disengagement of the clutch from the engine causes the revs to drop. Without bringing up the revs somehow to help the engine speed match the wheel speed in the gear you're about to use, you'll typically get a sudden jolt when re-engaging the clutch as physics brings everything back into sync. That jolt can be a big problem when you're moving along swiftly, causing instability or even a loss of traction, particularly in rear-wheel-drive cars. So the point of rev matching is to blip the throttle simultaneously as you downshift gears in order to bring the engine speed to a closer match with the wheel speed before you re-engage the clutch in that lower gear, in turn providing a much smoother downshift. When braking is thrown in, you get heel-toe downshifting, which involves some dexterity to use all three pedals at the same time with just two feet – clutch in, slow the car while revving, clutch out. However, even if you're aware of heel-toe technique and the basic elements of how to perform a rev match, perfecting it to the point of making it useful can be difficult.

Meet the mother-daughter team that's worked on almost every Chevy Volt

Sun, May 11 2014It's Mother's Day, and we're soft enough we love our mothers enough to share a new video from General Motors with you. In it, we meet Monique Watson (left) and Evetta Osbourne, a mother-daughter team that works at the Detroit-Hamtramck Assembly where GM makes the Chevy Volt (along with all of GM's other plug-in hybrids: the Opel Ampera, Holden Volt and Cadillac ELR). The two work side-by-side and have installed the lithium-ion battery pack on almost all of those vehicles - nearly 80,000 of them - since GM started making the pre-production Volts in 2009. In a prepared statement, Watson said that she likes working next to her mom, day in and day out, and they the two are totally in sync when it comes to putting the 400-pound, 16.5-kWh packs into the vehicle undersides. They two can also share stories throughout the day, and Watson said, "The arrangement has absolutely improved our relationship." Osborne started working at Detroit-Hamtramck in 1999, Watson since 2006. If you're driving a Volt today, you probably have them to thank for doing a bit of the work putting your car together. See a short video of them in action below. It's Always Mother's Day for Detroit-Hamtramck Duo Mother, daughter install lithium-ion battery pack in nearly all GM electric vehicles 2014-05-08 DETROIT – For Detroit resident Evetta Osborne, every day is Mother's Day. That's because she literally works side by side with her daughter, Monique Watson, at General Motors' Detroit-Hamtramck assembly plant. They have installed the lithium-ion battery pack on nearly every Chevrolet Volt, Opel Ampera, Holden Volt, and Cadillac ELR since production began. In fact, apart from vacation days and an occasional sick day, the mother-daughter duo has installed almost every battery pack since the Volt was in pre-production in 2009. The ELR launched earlier this year. All told – including Ampera – that's more than 80,000 electric vehicles. "We're a good team and our relationship is secondary when it comes to performing our jobs – but it's great to work alongside my daughter, said Osborne, a mother of five. Because the battery packs weigh more than 400 pounds each, automatic guided vehicles – robotic carts that use sensors to follow a path through the plant – deliver them just as the vehicle body structures glide into position overhead. The carts then lift the T-shaped packs, and Osborne and Watson guide them into the chassis and secure each one with 24 fasteners.