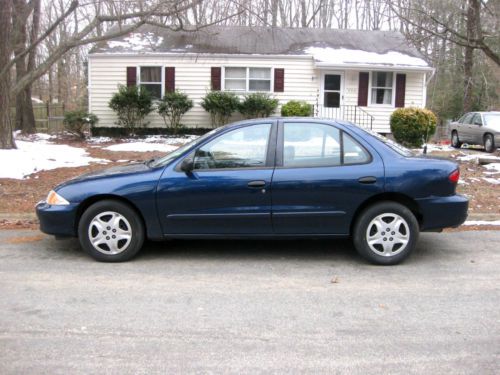

2001 Chevrolet Cavalier Sedan Auto A/c Cng / Gas Bi-fuel 4 Door 4 Cylinders on 2040-cars

Phoenix, Arizona, United States

Chevrolet Cavalier for Sale

Auto Services in Arizona

Vistoso Automotive ★★★★★

Vette Shoppe ★★★★★

Tempe Imports ★★★★★

Suntec Auto Glass & Tinting ★★★★★

Smarts Automotive ★★★★★

Real Fast Auto Glass ★★★★★

Auto blog

Chevy Volt 'Drive My Way' test cuts out the dealership

Tue, Dec 22 2015Last month, the 2016 Chevrolet Volt won the 2016 Green Car of the Year Award at the Los Angeles Auto Show. Awards are nice, but General Motors is now offering to make some folks' familiarity with the second-generation Volt a little more personal. Chevy is enacting what it calls the "Drive My Way" program, where the automaker brings a 2016 Volt directly to some prospective buyers for a 30-minute test drive with no dealer required, according to Hybrid Cars. Kind of like Tesla, only different. RedCap Valet is administering the program and is helping to track drivers' behind-the-wheel behavior, including keeping records on speed, acceleration, and braking habits. General Motors representatives didn't respond to a our request for further details about how many people will be chosen for the program or how these folks were picked to participate in "Drive My Way." Through November, the Volt's sales were down 23 percent from a year earlier to about 13,000 units, so any momentum for the 2016 version is a good thing. If you're just looking for numerical improvements, the new version has got you covered. It can go as far as 53 miles on electricity alone (about 15 miles further than the previous generation model) and it's got better miles per gallon and MPGe ratings as well. Of course, numbers alone aren't usually enough sell a car. Experience counts. So we ask, dear readers, if having a 2016 Volt brought to you for a half-hour test drive might make it more likely that you'll buy one of these extended-range plug-in vehicles. While you're waiting for a new Volt to arrive at your house, you can take a look here for our First Drive review. Related Video: Featured Gallery 2016 Chevrolet Volt: First Drive View 24 Photos News Source: Hybrid Cars Green Chevrolet GM test drive volt extended-range plug-in

Dodge Demon 170 reveal experience, Supercharging a non-Tesla and the BMW XM | Autoblog Podcast #774

Fri, Mar 31 2023In this episode of the Autoblog Podcast, Editor-in-Chief Greg Migliore is joined by Road Test Editor Zac Palmer. They start off with what it was like to be at the reveal for the 2023 Dodge Challenger SRT Demon 170 out in Las Vegas. From there, they explore news of the 2024 Acura Integra Type S being revealed to have 5 more horsepower than the Civic Type R. And to round out the news section, there's an Explorer EV out, but it's only for Europe. After that, the two discuss the cars they've been driving, including the 2023 BMW XM, VW Jetta Sport with a manual transmission, our long-term Toyota Sienna minivan and what it was like to charge our long-term Kia EV6 on a Tesla Supercharger. Lastly, the pair spend some money to help a listener buy a car for their daughter who is just starting to drive. Autoblog Podcast # 774 Get The Podcast Apple Podcasts – Subscribe to the Autoblog Podcast in iTunes Spotify – Subscribe to the Autoblog Podcast on Spotify RSS – Add the Autoblog Podcast feed to your RSS aggregator MP3 – Download the MP3 directly Rundown News Dodge reveals the Challenger SRT Demon 170 in Las Vegas The Acura Integra Type S will officially have 320 horsepower Electric Ford Explorer revealed in Europe What we're driving 2023 BMW XM 2023 VW Jetta Sport Supercharger experience with long-term Kia EV6 Long-term 2023 Toyota Sienna Spend My Money Feedback Email – Podcast@Autoblog.com Review the show on Apple Podcasts Autoblog is now live on your smart speakers and voice assistants with the audio Autoblog Daily Digest. Say “Hey Google, play the news from Autoblog” or "Alexa, open Autoblog" to get your favorite car website in audio form every day. A narrator will take you through the biggest stories or break down one of our comprehensive test drives. Related video: 2023 Dodge Challenger SRT Demon 170 reveal

Super Bowl LVII car commercial roundup: Watch them all here

Mon, Feb 13 2023Fewer automakers than usual spent money advertising during Super Bowl LVII. In total, there were only five traditional ad spots from three big OEMs. A number of car-adjacent ads aired during the Big Game, too, and we’ll bring you those ads in this roundup alongside the more obvious ones. WeÂ’ve compiled all of the automotive-related commercials for you here in this post so you donÂ’t have to go searching for them elsewhere. Read on below to see what aired as the Kansas City Chiefs defeated the Philadelphia Eagles. Ram's Super Bowl spot offers a cure for 'Premature Electrification' This commercial revealed the new electric Ram Rev pickup, and itÂ’s themed like a prescription ad for an antidote to "Premature Electrification.” A concerned narrator in the Ram spot asks if you're afraid that going electric too soon will mean "you might not be able to last as long as you like," and there's a guy on a pier who's going to need some new equipment if he wants to catch fish. We're also told there are "options being designed to extend range in satisfying ways," so if this truck isn't right for you, you have choices. All the commercial's missing is a silly medical marketing name and six seconds of speed-reading gibberish about side effects like intestinal bleeding and death. Which are two more good things. Jeep 4xe Super Bowl commercial highlights modern version of 'Electric Boogie' JeepÂ’s “Electric Boogie” commercial follows the Wrangler 4xe and Grand Cherokee 4xe in a variety of simulated off-road situations. Though fun, the soundtrack is the real star of the show. The songÂ’s original artist, Marcia Griffiths, was joined by Grammy winner Shaggy, Jamila Falak, Amber Lee, and Moyann on the track. The modernized re-recording celebrates 40 years since GriffithsÂ’ original track, and Jeep says the track is available for streaming now. Kia returns to the Super Bowl with the tale of 'Binky Dad' This year, Kia follows the adventure of "Binky Dad" in his quest to fetch his daughter's lost pacifier, which naturally takes him over just about every bit of terrain you might encounter upon leaving the civilized confines of Southern California for the not-so-civilized mountains of ... probably also California. It features the refreshed 2023 Kia Telluride, which probably doesnÂ’t need much advertising to see these days, but Kia went for it with the strong three-row SUV anyway.

1999 cavalier

1999 cavalier 2003 chevy cavalier

2003 chevy cavalier Parts car

Parts car 1997 cavalier 5 spd. 2.2 litre air power locks

1997 cavalier 5 spd. 2.2 litre air power locks 2002 chevy cavalier no key parts missing trunk won't shut mileage unknown

2002 chevy cavalier no key parts missing trunk won't shut mileage unknown 2001 chevrolet cavalier cng compressed natural gas! no reserve *tax credit car*

2001 chevrolet cavalier cng compressed natural gas! no reserve *tax credit car*