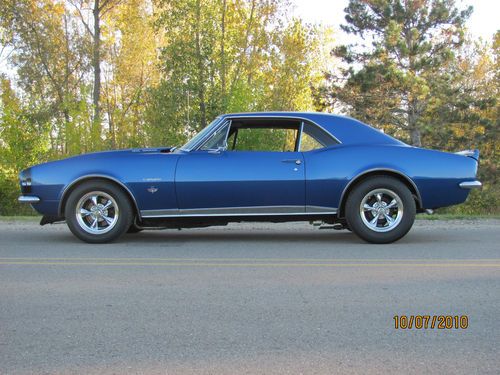

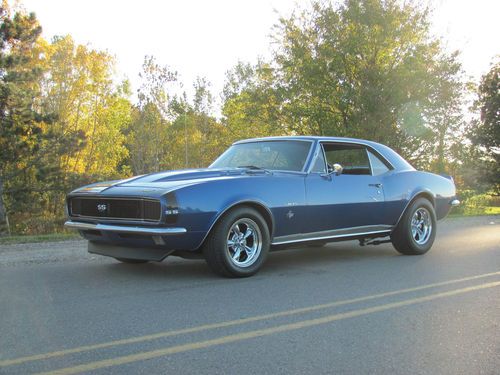

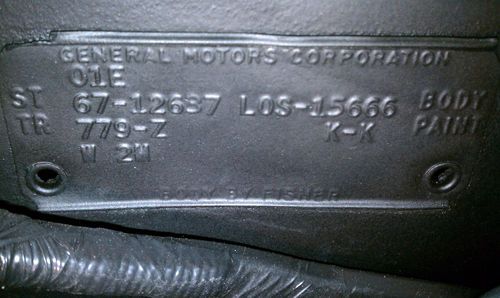

1967 Camaro on 2040-cars

Howell, Michigan, United States

Body Type:Coupe

Engine:8 CYLINDER

Vehicle Title:Clear

Fuel Type:Gasoline

For Sale By:Private Seller

Interior Color: Black

Make: Chevrolet

Number of Cylinders: 8

Model: Camaro

Trim: Coupe

Drive Type: GAS

Mileage: 0

Exterior Color: Blue/Black

Warranty: Vehicle does NOT have an existing warranty

Chevrolet Camaro for Sale

2010 chevy camaro 2ss 6.2l v8 6-speed manual roof black/orange leather 20" wheel

2010 chevy camaro 2ss 6.2l v8 6-speed manual roof black/orange leather 20" wheel 1998 chevrolet camaro base coupe 2-door 3.8l(US $2,000.00)

1998 chevrolet camaro base coupe 2-door 3.8l(US $2,000.00) 2002 camaro z28 6spd m6 hardtop ls1 17k miles

2002 camaro z28 6spd m6 hardtop ls1 17k miles 2002 chevrolet camaro ss 5.7l 475hp(US $18,000.00)

2002 chevrolet camaro ss 5.7l 475hp(US $18,000.00) 1999 chevrolet camaro base convertible 2-door 3.8l(US $2,995.00)

1999 chevrolet camaro base convertible 2-door 3.8l(US $2,995.00) 1995 chevy camaro z28 convertible ice cold a/c great shape sports car! florida!!

1995 chevy camaro z28 convertible ice cold a/c great shape sports car! florida!!

Auto Services in Michigan

Winners Auto Service Inc ★★★★★

Wally`s Garage ★★★★★

Vehicle Accessories ★★★★★

Vanderhaag Car Sales ★★★★★

Used Car Factory Inc ★★★★★

University Auto Care ★★★★★

Auto blog

GM marks 500 million vehicles

Tue, May 5 2015General Motors is marking a major global milestone, as 500 million vehicles have rolled off its assembly lines since the company's founding in 1908. To mark the occasion, the automaker is continuing to invest in production and offering a one-time discount to some customers. GM North America boss Alan Batey used the festivities to announce the Fairfax Assembly factory in Kansas as one of the sites earmarked for the company's $5.4 billion in upcoming investments. The plant will get $174 million of that money for new equipment and technology to build the 2016 Chevrolet Malibu. Among the upgrades will be a shake-and-rattle booth that will simulate road conditions to find squeaks. To commemorate both the production milestone and the Fairfax plant, Batey and company CEO Mary Barra also gave away a 2016 Malibu to a wounded Iraqi war veteran, and the two execs announced that in the third week in May all GM employees can share a one-time customer appreciation discount with friends to help get them into the automaker's products. Barra also gave a speech to the workers there about some of the other milestone's in the company's history, which you can read below. Innovation on the Line: GM Manufacturing Milestones Many of General Motors' most important innovations have occurred behind the scenes, in its manufacturing facilities. Concepts such as changeover, flexible assembly, automation, computer simulation, machine vision and robotics were developed at GM. Over the decades these innovations have helped enable improvements in vehicle quality, efficiency and competitiveness. 1901: Ransom Olds' famous Curved Dash Oldsmobile, designed with simplicity, reliability and value in mind, was the first American car built in a factory designed specifically for automobiles and in standardized volume production. GM acquired Oldsmobile in 1908. 1908: Cadillac wins the Dewar Trophy, Europe's most prestigious award for precision and excellence in manufacturing, by demonstrating the auto industry's highest standards for precision and interchangeability of parts by disassembling three Cadillacs and mixing the parts randomly before reassembling and driving them before a contingent of judges. 1922: GM hires William Knudsen to lead Chevrolet's turnaround. Knudsen implements flexible mass production, which helps Chevrolet incorporate annual styling changes and take market share from Ford.

GM sees 'strong year' in 2018, then gold in Chevy Silverado for 2019

Tue, Jan 16 2018DETROIT — General Motors said on Tuesday it expects earnings in 2018 to be largely flat compared with 2017, but that profits should pick up pace in 2019 as its revamped line of high-margin pickup trucks hits the U.S. market. The 2018 earnings outlook was above market expectations, sending GM shares up more than 3 percent in premarket trading. "GM had a very good 2017 as we continued to transform our company to be more focused, resilient and profitable," GM Chief Executive Mary Barra said in a statement. "We are positioned for another strong year in 2018 and an even better one in 2019." GM and its Detroit rivals, Ford and Fiat Chrysler Automobiles, are bringing on new trucks at a time when overall U.S. new vehicle sales have been falling, but truck sales continue to grow as consumers abandon passenger cars in favor of pickups, SUVs and crossovers. GM on Saturday fired a new round in the battle for profits from one of the U.S. auto industry's most lucrative segments when it showed a new generation of its Chevrolet Silverado pickup truck at the Detroit auto show. The new Silverado, a highlight of the event, is the successor to GM's best-selling vehicle in North America. Sales of the current Silverado rose nearly 2 percent to 585,000 vehicles in 2017. In the coming months, the company will also reveal a revamped GMC Sierra pickup truck. U.S. new vehicle sales fell 2 percent in 2017 after hitting a record high in 2016, and are expected to drop further in 2018 as interest rates rise and more late-model used cars return to dealer lots to compete with new ones. GM said on Tuesday that while it retools a factory in Ft. Wayne, Indiana, to make the new pickup trucks, it will shift some production to an Oshawa, Ontario, plant in order to avoid missing sales in a hot market for the vehicles. The No. 1 U.S. automaker said it will record a $7 billion non-cash charge for its fourth-quarter 2017 earnings related to deferred tax assets. GM said it expects capital expenditure in 2018 of around $8.5 billion, about $1 billion of which will go toward funding self-driving car technology. Last week, the company said it is seeking U.S. government approval for a fully autonomous car — one without a steering wheel, brake pedal or accelerator pedal — to enter the automaker's first commercial ride-sharing fleet in 2019. GM said it expects 2017 earnings per share at the high end of its previously forecast range of $6 to $6.50.

Meet the mother-daughter team that's worked on almost every Chevy Volt

Sun, May 11 2014It's Mother's Day, and we're soft enough we love our mothers enough to share a new video from General Motors with you. In it, we meet Monique Watson (left) and Evetta Osbourne, a mother-daughter team that works at the Detroit-Hamtramck Assembly where GM makes the Chevy Volt (along with all of GM's other plug-in hybrids: the Opel Ampera, Holden Volt and Cadillac ELR). The two work side-by-side and have installed the lithium-ion battery pack on almost all of those vehicles - nearly 80,000 of them - since GM started making the pre-production Volts in 2009. In a prepared statement, Watson said that she likes working next to her mom, day in and day out, and they the two are totally in sync when it comes to putting the 400-pound, 16.5-kWh packs into the vehicle undersides. They two can also share stories throughout the day, and Watson said, "The arrangement has absolutely improved our relationship." Osborne started working at Detroit-Hamtramck in 1999, Watson since 2006. If you're driving a Volt today, you probably have them to thank for doing a bit of the work putting your car together. See a short video of them in action below. It's Always Mother's Day for Detroit-Hamtramck Duo Mother, daughter install lithium-ion battery pack in nearly all GM electric vehicles 2014-05-08 DETROIT – For Detroit resident Evetta Osborne, every day is Mother's Day. That's because she literally works side by side with her daughter, Monique Watson, at General Motors' Detroit-Hamtramck assembly plant. They have installed the lithium-ion battery pack on nearly every Chevrolet Volt, Opel Ampera, Holden Volt, and Cadillac ELR since production began. In fact, apart from vacation days and an occasional sick day, the mother-daughter duo has installed almost every battery pack since the Volt was in pre-production in 2009. The ELR launched earlier this year. All told – including Ampera – that's more than 80,000 electric vehicles. "We're a good team and our relationship is secondary when it comes to performing our jobs – but it's great to work alongside my daughter, said Osborne, a mother of five. Because the battery packs weigh more than 400 pounds each, automatic guided vehicles – robotic carts that use sensors to follow a path through the plant – deliver them just as the vehicle body structures glide into position overhead. The carts then lift the T-shaped packs, and Osborne and Watson guide them into the chassis and secure each one with 24 fasteners.