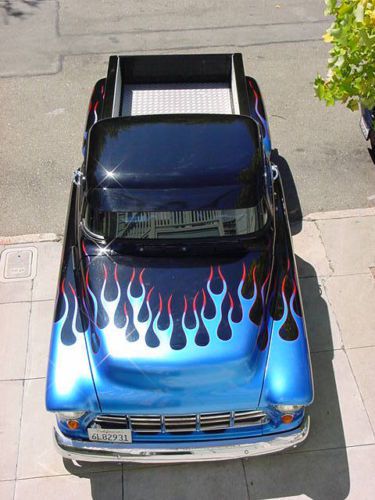

1955 Chevrolet Pickup Chopped Flamed Import From Au Right Hand Drive Gaylord on 2040-cars

San Jose, California, United States

|

CHEVY 1955

Pickup From Australia

OWNER: MR Y:

Trunk cover .............. Gaylord fiberglass trunk cover Black

The car was built 10-15 years ago in AU by a guy there who goes by the name "Juice" and is well known to build nice Harley bikes. He did all the work and as well as painted the car ..... The car was dropped over a complete GM Holden / Camaro chassis with power disk breaks, power steering and IFS front suspension Air bags in all 4 corners and pump and tank in the rear with controls on the dash Car drives real nice and ready for the summer - all I would change would be a new set of trims to keep up with the trends :) Dis-closer - that can not be seen in the pictures : there is 3 small cracks on the roof , one paint scratch on the left front fender no dents on the car That's it Folks...... Videos of the car : |

Chevrolet Other Pickups for Sale

Auto Services in California

ZD Autobody ★★★★★

Z Benz Company Inc ★★★★★

Www.Bumperking.Net ★★★★★

Working Class Auto ★★★★★

Whittier Collision Center #2 ★★★★★

West Tow & Roadside Servce ★★★★★

Auto blog

Why an independent rear suspension for GM's new, full-sized SUVs wasn't easy

Mon, Dec 23 2019A Motor Trend report last month laid out how Cadillac's 4.2-lier twin-turbo Blackwing V8 could be an orphan due to cost concerns in the GM empire. Last-minute chassis changes to Cadillac's new sedans and XT6 crossover led to engine bays that couldn't fit the Blackwing. On the SUV side, according to the report, the new independent rear suspension for big people haulers cost so much to implement that GM ruled out reworking the Escalade to accept the Blackwing. At least one commenter rightly asked how could a suspension swallow that much money. A new piece in Motor Trend has the answer. The excellent Alissa Priddle spoke to Tim Herrick, GM's executive chief engineer for full-size trucks, about why the clean-sheet IRS cost "multimillions of dollars."Â First, GM would need to build a new body shop at the Arlington, Texas plant that assembles the automaker's big SUVs to stamp the numerous wholly new parts and panels accommodating an IRS. Then GM would need to design and pay for a new assembly process. On top of those up-front costs, there was the incremental cost of the four-link IRS components being more expensive than those in the trucks' former leaf-sprung solid axles. Herrick endured so many rejections for so long that he remembers the date and time when he got approval for the new unit. He said it came down to a meeting where he told a higher-up, "I'll make you a deal: If we get to the reveal, or if we launch this and you think this was a dumb idea, I'll hand you my badge and let you walk me out." Head to Motor Trend to read the full story. Based on Herrick being on stage to help present the new SUVs to the press, and on our First Ride in the new Chevrolet Tahoe and Suburban at GM's Milford Proving Grounds, it appears this will have a happy ending for all involved. Furthermore, since Herrick worked on the T1 platform that supports the big SUVs as well as the light- and heavy-duty pickups, he understood the demands on the commercial side, too. That could be why when Roadshow asked Tim Asoklis, chief engineer of the Tahoe and Suburban, if the new IRS could endure life in the Chevrolet Silverado and GMC Sierra, Asoklis answered, "Oh, absolutely." Related Video: Â Â

GM says its electric pickup truck is 'in development'

Thu, Jun 6 2019GM President Mark Reuss just reiterated the company's support for an electric pickup project. He also claimed that GM is going to be selling its future electric cars at "very average transaction prices" during the same conference with Wall Street analysts. Previously, Mary Barra informed the world of GM's electric pickup truck aspirations, but didn't tell us anything else. Reuss says the truck is already in development, though, according to a Wards Auto report. "We will have a complete electric lineup, including a pickup truck that's in development," Reuss said. This comment marks the second time GM has gone on the record about its intentions to bring an electric pickup to market. Additionally, Reuss said GM's third-generation global EV platform will be used to help develop the electric pickup. This platform was recently announced to underpin at least 20 new EVs from GM in the future — the platform itself is slated to be unveiled in 2021. Of course, this platform will be flexible and modular to allow various body styles to be used with it, a truck being one of those. Reuss still hasn't said what GM brand the pickup will be sold under, or what class of truck it will be. GM thinks this new platform is also going to be what helps it drive down the cost of building EVs. "We'll reach parity a lot sooner than people think," Reuss said comparing EVs to traditional gas-powered engines. "We're driving down the cost of batteries and the whole EV in general." As for electric pickups, Ford is also deep in development of its own electric F-150. However, neither of these truck projects have official timelines on them, so we can't say when they'll hit the market. For now, the cross-town rivals are both in development with their respective electric pickups. Even further across town is Rivian (in which Ford just invested half a billion dollars), a company that says its electric R1T pickup is right around the corner, with the official due date being end of 2020 for the time being. Green Chevrolet GMC Green Culture Green Driving Truck Electric Future Vehicles

Chevy to resume engine-building program for 2015 Corvette Z06

Thu, Jan 8 2015One of Chevrolet's most popular and unique customer features is set to return for 2015, as the company has announced that the Engine Build Experience is back. Interested owners will be able to screw together their engines beginning in March. The $5,000 option (which does not include the cost of travel) will give future owners of the 2015 Corvette Z06 the chance to screw together their car's actual 6.2-liter, supercharged V8. Available on each of the Z06's three trims, the Engine Build Experience includes a day at the Performance Build Center, instruction from an engine assembly tech, photographs of the experience and a personalized engine plaque. Once the build process is completed, the engine will (eventually) be fitted under the hood of the customer's personal Z06. "Chevrolet recognizes the passion customers have for Corvette and the Engine Build Experience offers them a truly unique opportunity for hands-on involvement in the creation of the heart of their new car," Corvette product manager Harlan Charles. "It's important for customers to understand their engine won't be installed the day after they built it. It will flow into the scheduling process for vehicle assembly, which depends on a number of logistical variables." Scroll down for the official announcement of the Z06's Engine Build Experience, available below. Exclusive Corvette Engine Build Experience Returns Program renewed for supercharged LT4 engine at new Bowling Green build center 2015-01-07 BOWLING GREEN, Ky. – Chevrolet announced today it is resuming the exclusive Engine Build Experience for Corvette Z06 customers – the only program of its kind for supercar customers. Starting in March 2015, Corvette Z06 customers will be able to assemble the 650-hp supercharged LT4 engine for their cars at the new Performance Build Center inside the Bowling Green Assembly Plant. "Chevrolet recognizes the passion customers have for Corvette and the Engine Build Experience offers them a truly unique opportunity for hands-on involvement in the creation of the heart of their new car," said Harlan Charles, Corvette product manager. "It's a chance to bond with their new car." The Engine Build Experience is selected with order code PBC and is offered on all Z06 trim levels.

1954 chevy pickup truck great patina rat rod classic

1954 chevy pickup truck great patina rat rod classic Hard to find 1949 barn find 3100 dark blue,rat rod,patina,shop truck chevrolet

Hard to find 1949 barn find 3100 dark blue,rat rod,patina,shop truck chevrolet 1952 chevy pickup

1952 chevy pickup 1961 chevy apache 10 - rat rod!!!

1961 chevy apache 10 - rat rod!!! 1951 chevy pickup

1951 chevy pickup 1951 chevrolet 5 window 2 dr pickup 350 cui

1951 chevrolet 5 window 2 dr pickup 350 cui