1967 Chevellle Ss 396 on 2040-cars

Gilbert, Arizona, United States

Engine:V8

Vehicle Title:Clear

Fuel Type:gas

For Sale By:owner

Interior Color: Black

Model: Chevelle

Number of Cylinders: 8

Trim: 2 door hardtop

Drive Type: rwd

Mileage: 99,999

Exterior Color: White

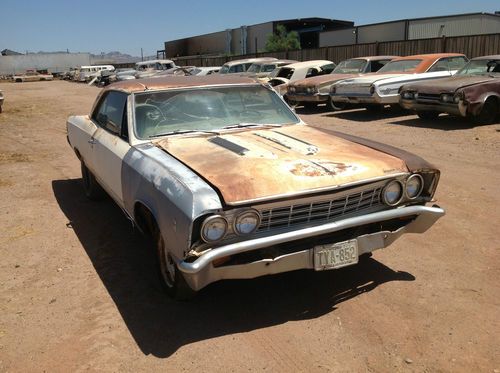

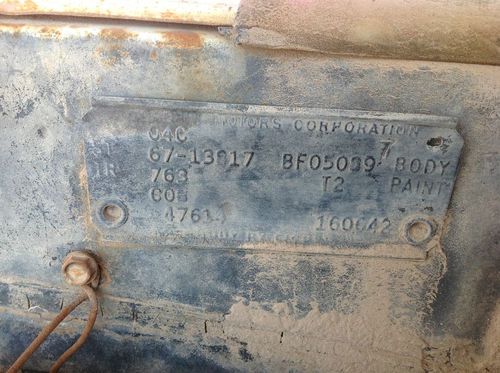

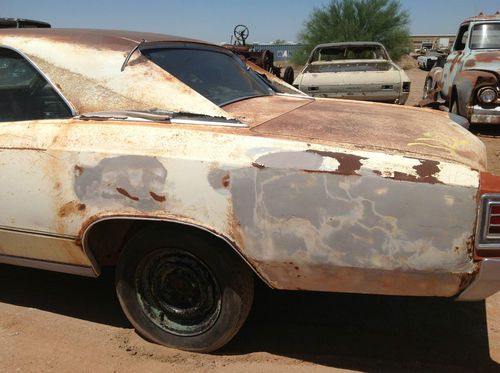

This is a 1967 Chevelle SS 396. True 138 code SS. Just rescued from the Arizona desert. Originally a white car with black bucket seat interior. Currently has small block and 3 speed on the floor. Was a 4 speed car. Lots of surface rust the interior is sunbaked. The floor pans look good from underneath. Not sure on condition of trunk pan. If you have other questions, please call 435-770-3337 Thanks

Chevrolet Chevelle for Sale

Convertible ac car with power steering top and brakes! solid body & new interior

Convertible ac car with power steering top and brakes! solid body & new interior 1971 chevelle v8 malibu 2 door hardtop runs and drives ss 1968 - 1972 1969 1968

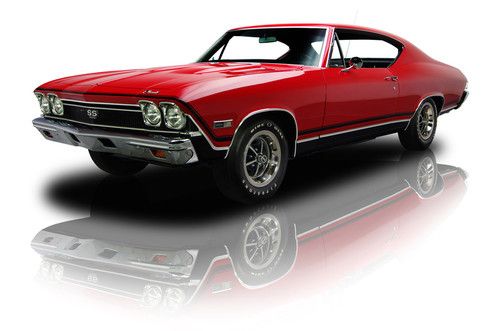

1971 chevelle v8 malibu 2 door hardtop runs and drives ss 1968 - 1972 1969 1968 Restored 1968 chevrolet chevelle ss 396 4 speed!(US $47,900.00)

Restored 1968 chevrolet chevelle ss 396 4 speed!(US $47,900.00) Documented frame off restored chevelle 355 v8 4 speed(US $46,900.00)

Documented frame off restored chevelle 355 v8 4 speed(US $46,900.00) 1970 chevrolet chevelle ss ls6 454/450 hp 4 speed,12 bolt, older restoration

1970 chevrolet chevelle ss ls6 454/450 hp 4 speed,12 bolt, older restoration 1971 chevelle

1971 chevelle

Auto Services in Arizona

Windshield Replacement Phoenix ★★★★★

Valley Express Auto Repair ★★★★★

Tj`s Speedometer Repair ★★★★★

Super Discount Transmissions ★★★★★

Sun Devil Auto ★★★★★

Storm Auto Glass ★★★★★

Auto blog

Meet the mother-daughter team that's worked on almost every Chevy Volt

Sun, May 11 2014It's Mother's Day, and we're soft enough we love our mothers enough to share a new video from General Motors with you. In it, we meet Monique Watson (left) and Evetta Osbourne, a mother-daughter team that works at the Detroit-Hamtramck Assembly where GM makes the Chevy Volt (along with all of GM's other plug-in hybrids: the Opel Ampera, Holden Volt and Cadillac ELR). The two work side-by-side and have installed the lithium-ion battery pack on almost all of those vehicles - nearly 80,000 of them - since GM started making the pre-production Volts in 2009. In a prepared statement, Watson said that she likes working next to her mom, day in and day out, and they the two are totally in sync when it comes to putting the 400-pound, 16.5-kWh packs into the vehicle undersides. They two can also share stories throughout the day, and Watson said, "The arrangement has absolutely improved our relationship." Osborne started working at Detroit-Hamtramck in 1999, Watson since 2006. If you're driving a Volt today, you probably have them to thank for doing a bit of the work putting your car together. See a short video of them in action below. It's Always Mother's Day for Detroit-Hamtramck Duo Mother, daughter install lithium-ion battery pack in nearly all GM electric vehicles 2014-05-08 DETROIT – For Detroit resident Evetta Osborne, every day is Mother's Day. That's because she literally works side by side with her daughter, Monique Watson, at General Motors' Detroit-Hamtramck assembly plant. They have installed the lithium-ion battery pack on nearly every Chevrolet Volt, Opel Ampera, Holden Volt, and Cadillac ELR since production began. In fact, apart from vacation days and an occasional sick day, the mother-daughter duo has installed almost every battery pack since the Volt was in pre-production in 2009. The ELR launched earlier this year. All told – including Ampera – that's more than 80,000 electric vehicles. "We're a good team and our relationship is secondary when it comes to performing our jobs – but it's great to work alongside my daughter, said Osborne, a mother of five. Because the battery packs weigh more than 400 pounds each, automatic guided vehicles – robotic carts that use sensors to follow a path through the plant – deliver them just as the vehicle body structures glide into position overhead. The carts then lift the T-shaped packs, and Osborne and Watson guide them into the chassis and secure each one with 24 fasteners.

GM investing $439 million in Corvette plant

Fri, May 22 2015General Motors is slowly trickling out announcements about its $5.4 billion in US plant upgrades over the next three years. The latest one is something that fans of one of America's most beloved sports car will be happy about. The Bowling Green, KY, factory that assembles the Chevrolet Corvette is receiving $439 million of those funds to build a new paint shop. Covering 450,000 square-feet, the site will make painting the 'Vette more efficient and environmentally friendly. The upgrades there include robots that use paint more effectively, technology to eliminate sludge water, LED lighting to improve inspections, and less energy-intensive baking ovens. While the groundbreaking is already complete for the building, full construction is expected to begin this summer and take two years. This is the biggest upgrade for the Kentucky factory in a few years. In preparation for the latest Corvette, the Bowling Green plant received $131 million in 2011 for upgrades and to add more workers there. Related Video: Chevrolet Corvette Plant Gets $439 Million in Upgrades New, environment-friendly paint shop drives efficient production, retains 150 jobs 2015-05-21 BOWLING GREEN, Ky. – Torch Red, Shark Gray Metallic and Laguna Blue Tintcoat, three popular palate choices on the 2015 Corvette, kept the marketers who make up names working late. Now they can dream about more painstakingly precise pigments, thanks to a new paint shop that is among $439 million being invested at the only plant in the world that builds Chevrolet's iconic sports car. General Motors announced the moves today that include retaining 150 jobs and building the 450,000 square-foot paint shop that is almost half the size of the entire current production facility. The investment builds on approximately $135 million GM has invested in the plant over the last four years for the new Corvette Stingray and Performance Build Center. The announcement was followed by a groundbreaking event for the new paint shop. "The Corvette is one of Kentucky's most-cherished icons," said. Lt. Gov. Crit Luallen. "Such a significant expansion of the Bowling Green Assembly Plant will help the company remain competitive in the region and around the world." Construction of the new paint shop, which includes substantial technology upgrades, is planned to begin this summer and take approximately two years to complete. Corvette production schedules will be unaffected by the construction.

The real costs of keeping a Chevy Volt on the road

Wed, Sep 2 2015The release of the new, 2016 Chevy Volt is sure to bring a surge of used electric vehicles to the market as early adopters trade their older models in. Many of these cars are selling for a fraction of their original price, thanks in part to federal and state incentives that lowered the initial cost to the first owner, which opens these cars up to a whole new class of consumers. While the prices are getting attractive, potential buyers are still hesitant to buy a used EV due to uncertainty about service and repair costs, but there may be some good news on the horizon. The Chevy Volt comes with a battery warranty that is good for at least 8 years and 100,000 miles, but many of the Volts popping up on the market have passed that 100,000-mile mark. The threat of needing a new battery can be a deterrent, especially with some dealers quoting prices as high as $34,000 for a full "drive motor battery replacement." That sum is more than the MSRP of a 2016 model. Some of the fear of EV maintenance and repair comes from the mystery of the individual pieces that make up the drivetrain and charging system. If we take a look at the Volt in terms of analogs to a traditional internal-combustion vehicle, the outlook becomes a little more friendly. The Volt battery pack consists of three lithium-ion modules in a T-shaped arrangement, each of which can be serviced individually. Module 1 is made up of 90 cells and corresponds to GM part number 22954462, which retails for $3,258.33; module 2 is made up of 72 cells and corresponds to GM part number 22954463, which retails for $2,930.00; lastly, module 3 is made up of 125 cells and corresponds to GM part number 22954464, and retails for $4,933.33. These part numbers have been added to the dealer order systems but have not shown up in the distribution centers at this time. Although all three of the modules add up to a fairly large $11,121.66 total and are still on hold for dealer ordering, the good news is that in most cases these battery cell modules do not need to be replaced. There are many other individual pieces mounted on the battery pack that are serviceable, such as the Battery Energy Control Modules (BECM) and the Battery Interface Control Modules (BICM). These modules control and monitor the battery packs and charging system and have been known to fail while the lithium-ion battery cells are not at fault. Some have been replaced under warranty, but if you are stuck buying one they run about $255 a piece for the part.