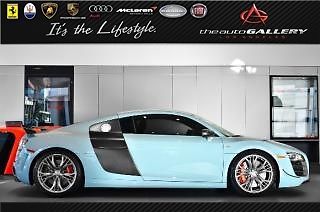

2011 Audi R8 5.2 on 2040-cars

Clearwater, Florida, United States

Audi R8 for Sale

2012 audi r8 2dr cpe man 4.2l bluetooth awd 4-wheel abs 4-wheel disc brakes a/c

2012 audi r8 2dr cpe man 4.2l bluetooth awd 4-wheel abs 4-wheel disc brakes a/c 2012 audi r8 2dr cpe auto quattro 5.2l gt

2012 audi r8 2dr cpe auto quattro 5.2l gt 2009 audi r8*4.2l*r-tronic*carbon fiber* premium pkg*rear camera*fully equipped*

2009 audi r8*4.2l*r-tronic*carbon fiber* premium pkg*rear camera*fully equipped* Audi r8 roadster v10 5.2 fsi free shipping 2011 2012(US $129,950.00)

Audi r8 roadster v10 5.2 fsi free shipping 2011 2012(US $129,950.00) 2012 audi 5.2l(US $139,800.00)

2012 audi 5.2l(US $139,800.00) 2008 r8 4.2 coupe, daytona gray pearl on black, carbon blade! 29,397mi $89,888!!

2008 r8 4.2 coupe, daytona gray pearl on black, carbon blade! 29,397mi $89,888!!

Auto Services in Florida

Zip Auto Glass Repair ★★★★★

Willie`s Paint & Body Shop ★★★★★

Williamson Cadillac Buick GMC ★★★★★

We Buy Cars ★★★★★

Wayne Akers Truck Rentals ★★★★★

Valvoline Instant Oil Change ★★★★★

Auto blog

J.D. Power customer survey of dealers counts Cadillac, Buick as big winners

Mon, 14 Apr 2014Cadillac and Buick have taken the trophies in J.D. Power's latest Customer Service Index Study examining satisfaction with dealer service. Surveying more than 90,000 owners and lessees of 2009-2013 model-year cars, the study found that those with pre-paid maintenance packages were ten percent more likely to buy their next car from the same brand.

Dealer satisfaction scores have improved overall, Cadillac nabbed the luxury segment ahead of Audi and Lexus, taking the crown that Lexus held last year. Buick keeps the mass-market dealer satisfaction win in the family, finishing ahead of Volkswagen and last year's winner GMC. The study also found that service department use of tablets increased customer satisfaction, as did "best practices" like "providing helpful advice." Who knew?

You can find details on those and more findings in the press release below.

Volkswagen Group previews its wares on eve of Geneva show

Mon, 05 Mar 2012The Volkswagen Group is comprised of 11 brands producing 240 vehicles across 49 factories throughout the world. So the best way to show off the range of the VW family is to cram a few thousand journalists and VIPs into a massive makeshift stand to outline the Group's goals, what's in the pipeline and what you'll be able to buy later this year.

To that end, VW pulled out all the stops on the eve of the 2012 Geneva Motor Show, bringing along 10 vehicles from across the range. We'll be delving into the details of each over the next two days of show coverage, but before that happens, you can read all about what we saw tonight from the cheap seats after the break.

Audi: record profit as 'biggest product initiative' in its history gets underway

Thu, Mar 16 2023Audi Group CEO Markus Duesmann  Even as the Audi Group (VOW.DE), VW’s luxury division, is in the midst of a huge EV transformation it still needs to perform where it counts — the bottom line. And so it is doing just that. On Thursday the Audi Group - which is dominated volume-wise by Audi, but also includes Bentley, Lamborghini, and Ducati - posted record revenue and operating profit in 2022. That shouldnÂ’t be a surprise given what the industry has been seeing at the highest end of the market - record performances despite macroeconomic jitters across the globe. But that it's happening as the group is noteworthy. “We are on the verge of the biggest product initiative in our history,” Audi Group CEO Markus Duesmann said at a news conference earlier on Thursday. “By 2025, we will have launched around 20 new models, more than 10 of which will be all-electric. We have set the course to go 100% electric. By 2027, we seek to offer an all-electric vehicle in each core segment.”  This is all part of Audi GroupÂ’s Vorsprung 2030 plan, which seeks to have all of the groupÂ’s new models be electric by 2026 — and to end traditional gas-powered engine production by 2033. To that end, the group saw EV deliveries jump 44% (in 2022) compared to 2021 to over 118,000 vehicles, with the share of EVs rising to 7.2% from 4.8% in the prior year. Audi is also launching its first EV using the PPE (premium platform electric), which was developed together with Porsche. That EV, the Audi Q6 e-tron, will be unveiled later this year. (Past Audi EVs shared corporate parent VWÂ’s electric platform.) “With the Audi Q6 e-tron, e-mobility is coming from Ingolstadt (Audi HQ) for the first time,” Duesmann said in a statement. “To this end, weÂ’re also building a dedicated battery assembly facility on site. This will enable us to retain important know-how here in Germany and train our employees in future fields.” AudiÂ’s German rivals of course are also leaning in hard on their EV transformations. That makes it all the more important that Audi get its EV strategy right—and launched in a timely manner.