2018 Toyota Sienna L Minivan 4d on 2040-cars

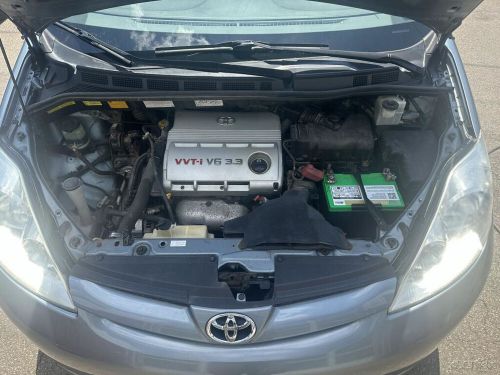

Engine:V6, 3.5 Liter

Fuel Type:Gasoline

Body Type:Passenger

Transmission:Auto, 8-Spd w/Direct Shft

For Sale By:Dealer

VIN (Vehicle Identification Number): 5TDZZ3DC3JS964898

Mileage: 148329

Make: Toyota

Trim: L Minivan 4D

Features: --

Power Options: --

Exterior Color: Blue

Interior Color: Beige

Warranty: Unspecified

Model: Sienna

Toyota Sienna for Sale

2006 toyota sienna le 7-passenger(US $2,995.00)

2006 toyota sienna le 7-passenger(US $2,995.00) 2022 toyota sienna le(US $34,885.00)

2022 toyota sienna le(US $34,885.00) 2014 sienna le 8-passenger 4dr mini-van(US $9,995.00)

2014 sienna le 8-passenger 4dr mini-van(US $9,995.00) 2023 toyota sienna xle(US $42,398.00)

2023 toyota sienna xle(US $42,398.00) 2006 toyota sienna(US $2,400.00)

2006 toyota sienna(US $2,400.00) 2020 toyota sienna(US $18,800.00)

2020 toyota sienna(US $18,800.00)

Auto blog

Toyota getting into 3D printing with i-Road in Tokyo

Mon, May 11 2015Think of it as Pimp My Ride for the Japanese green concept car set. Toyota is further publicizing its funky, really skinny, leaning i-Road electric concept vehicle by putting on a contest that, among other things, encourages folks to customize parts of the car's surface via 3D printing. Hey, it is a really small car. Toyota's Open Road Project in Tokyo, which will last about a year and will let about 100 participants work with 10 vehicles, also includes a component that lets contestants find the most creative parking spots by seeking out "small unused spaces with access to plug sockets" (we're sure Tokyo is full of them). What grabbed us, though, was the possibility of printing out panels for a three-wheeled car that's less than eight feet long and less than three feet wide. Earlier this year, we reported that Toyota would add five i-Road vehicles to a Tokyo carsharing pilot project. Toyota's unusual promotions for the admittedly unusual concept two-seater date back to early 2013, when the Japanese automaker featured a video of four i-Roads dancing their way through a sun-kissed Mediterranean village. Meantime, take a look at Toyota's press release below, and get more information on the project here.

Toyota cuts production target by 300,000 vehicles due to parts and chips shortages

Sat, Sep 11 2021TOKYO - Toyota cut its annual production target by 300,000 vehicles on Friday as rising COVID-19 infections slowed output at parts factories in Vietnam and Malaysia, compounding a global shortage of auto chips. "It's a combination of the coronavirus and semiconductors, but at the moment it is the coronavirus that is having the overwhelming impact," Kazunari Kumakura, an executive at the world's biggest car maker, said after the company revised its production target. Unlike other big global automakers that were forced earlier to scale back production plans, Toyota had managed to avoid cuts to output because it had stockpiled key components along a supply chain hardened against disruption following northeast Japan's devastating earthquake in 2011. Toyota's announcement on Friday is a further sign that no part of the global car industry has escaped the affects of a pandemic that has sapped sales and is hobbling its ability to take advantage of the recovery in demand that followed the initial waves of COVID-19. Car sales in China in August fell by almost a fifth from a year earlier because there were fewer vehicles for people to buy. Toyota now expects to build 9 million vehicles in the year to March 31, rather than 9.3 million. It did not revise its 2.5 trillion yen ($22.7 billion) operating profit forecast for the business year. Adding to a 360,000-vehicle cut in worldwide production in September, Toyota said on Friday it will reduce output by a further 70,000 this month and by 330,000 in October. It hopes to make up some of that lost production before its year-end. Demand for chips has soared during the pandemic as consumer electronic companies rush to meet stay-at-home demand for their smartphones, tablets and other devices. A heavy reliance on Southeast Asian factories for parts is a headache for Toyota, but its also a problem for its rivals that have struggled with what Volkswagen has described as "very volatile and tight" chip supplies. The German carmaker has warned it may need to cut production further as a result. Ford last month shut down production at a plant in Kansas that builds its best-selling F-150 pick up because of parts supply woes, with Renault extending partial stoppages at factories in Spain. Mercedes this month said it expects chip shortages to significantly lower third quarter sales. (Reporting by Tim Kelly; Editing by Muralikumar Anantharaman and Kim Coghill) Plants/Manufacturing Lexus Toyota

Toyota expanding Aichi's test EV infrastructure in Japan

Sun, Nov 2 2014OK, now we're really confused. In the US, Toyota has been telling anyone who cares to listen that the future of advanced-powertrain technology is hydrogen fuel-cell vehicles, not electric ones. In China, a Toyota joint venture is looking at EVs. Over in Japan? They've just decided to pony up a little more for testing electric-vehicle technology. Maybe something's lost in translation. Toyota has been running an electric-vehicle charging station trial project in Japan's Aichi Prefecture during the past couple of years and is now ready to expand that program, adding 43 new charging stations to the 104 already present. Many of the EVSEs are in municipal-owned properties or in mountainous areas (where EV batteries drain the fastest). Toyota's expanded program started running in Kariya City, Toyota City, Toyohashi City and Nagakute City this month, and testing will extend until the end of next March. There's more in Toyota's press release below. Toyota's electric-vehicle presence is limited here in the US, as the low-production RAV4 crossover is the only model sold here. Toyota executive Craig Scott was recently quoted as saying that the company questions whether there is sufficient demand in the US for pure electric vehicles. With that in mind, Toyota will debut its hydrogen fuel cell model in the US in 2015. Toyota to Test Expansion of EV and PHV Charging Infrastructure in Japan Toyota City, Japan, October 31, 2014-Toyota Motor Corporation announces that it will be testing electric vehicle charging infrastructure in Aichi Prefecture from November 1 until March 15, 2015. The tests will involve standard chargers for use with vehicles such as plug-in hybrid vehicles (PHVs) and electric vehicles (EVs). The tests will be conducted jointly with four municipalities (Kariya City, Toyota City, Toyohashi City, and Nagakute City) and two companies (Toyota Industries Corporation and UNY Co., Ltd.), all of which are located in Aichi Prefecture. Toyota conducted similar tests in FY2012 and FY20131. In addition to targeting commercial, tourist, and accommodation facilities as in past tests, this year's tests will also involve cultural and social service facilities (including some in hilly and mountainous areas). Multiple chargers will be installed at certain commercial facilities where charger use was heavy in last year's tests. The aim will be to ascertain the optimal number and location of charging stations and their ease of use.