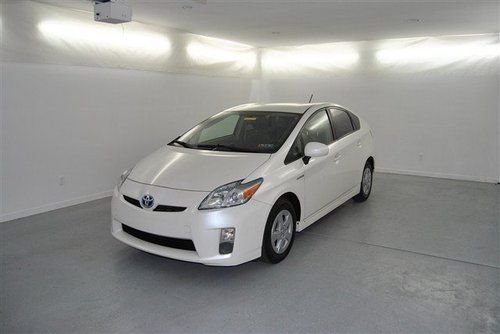

One Hybrid-electric 1.8l Cd Keyless Start Front Wheel Drive Power Steering A/c on 2040-cars

Aberdeen, South Dakota, United States

Engine:1.8L 1798CC 110Cu. In. l4 ELECTRIC/GAS DOHC Naturally Aspirated

For Sale By:Dealer

Body Type:Hatchback

Fuel Type:ELECTRIC/GAS

Transmission:Unspecified

Warranty: Unspecified

Make: Toyota

Model: Prius

Options: CD Player

Trim: Base Hatchback 4-Door

Power Options: Power Windows

Drive Type: FWD

Number of Doors: 4

Mileage: 37,214

Sub Model: One

Number of Cylinders: 4

Exterior Color: Red

Toyota Prius for Sale

12 c four hatchback hybrid navi heated seats entune apps bluetooth aux certified(US $21,992.00)

12 c four hatchback hybrid navi heated seats entune apps bluetooth aux certified(US $21,992.00) 11 ii hatchback hybrid electric fogs alloys aux cruise 51mpg 1 owner we finance(US $18,999.00)

11 ii hatchback hybrid electric fogs alloys aux cruise 51mpg 1 owner we finance(US $18,999.00) 2011 prius "4" 41,000 miles. winter gray metallic. garage kept. n/s

2011 prius "4" 41,000 miles. winter gray metallic. garage kept. n/s 2007 toyota prius 50mpg! no reserve auction! key less go! back up camera!

2007 toyota prius 50mpg! no reserve auction! key less go! back up camera! 2010 toyota prius

2010 toyota prius 2013 toyota prius three(US $24,999.00)

2013 toyota prius three(US $24,999.00)

Auto Services in South Dakota

Tri-State Windshield Repair ★★★★★

Schoney`s Quality Car-Trucks ★★★★★

Impact Auto ★★★★★

AutoZone ★★★★★

Auto Body Crafters ★★★★★

Steve`s Auto Body ★★★★

Auto blog

Toyota to pay $11 million after trial for fatal Camry crash

Wed, Feb 4 2015Years after Toyota's unintended acceleration fiasco, the company is still making headlines for cars with sticky gas pedals. A federal jury in Minnesota decided yesterday that Toyota should pay $11 million for its role in the crash of a 1996 Camry that resulted in three deaths and sent a man to jail. A stuck pedal caused the Camry of Koua Fong Lee to accelerate uncontrollably and impact an Oldsmobile Cutlass Ciera, killing its driver and his nine-year-old son, and paralyzing a six-year-old girl, who later died of her injuries. Two other passengers in the Olds were seriously injured. Lee spent nearly three years in prison on a charge of vehicular homicide, until the unintended acceleration recall erupted. He filed a motion for a new trial and won, and then joined the suit against Toyota filed by the victims and their families of the 2006 crash that left him imprisoned. The jury found Toyota 60 percent responsible for the accident, with the remaining 40 percent of blame going to Lee. Toyota has denied that the 1996 Camry, which wasn't included in the company's sweeping accelerator pedal recalls, was at fault. Toyota released a statement saying the company respects the jury's decision but believes the evidence clearly showed the vehicle wasn't the accident's cause. The company said it will study the record and consider its legal options. Under Minnesota law, the way the jury allocated fault means Toyota is responsible for paying all damages, minus 40 percent of the amount awarded to Lee, said Lee's attorney, Bob Hilliard. That brings Toyota's total liability to $10.94 million. Lee will receive $750,000 of that total. During the trial, Hilliard, told jurors there was a defect in the car's design. He said the Camry's auto-drive assembly could stick, and when tapped or pushed while stuck, it could stick again at a higher speed. He also accused Toyota of never conducting reliability tests on nylon resin pulleys that could be damaged under heat and cause the throttle to stick. "This is what makes the car go. This is what turns it into a torpedo, a missile, a deadly weapon," Hilliard said during his closing argument. Toyota said there was no defect in the design of the 1996 Camry. The company's attorney, David Graves, suggested that Lee was an inexperienced driver and mistook the gas pedal for the brake. Toyota also noted that Lee's car was never subject to the recalls of later-model Toyotas.

World Car Awards finalists snub American-branded vehicles — except for Bronco

Fri, Feb 2 2024The list of World Car Awards has been whittled down to 10 finalists, but only one American brand — Ford — appears among the remaining nine carmakers for this yearÂ’s top award. The Bronco is there, and it also is balloted as a finalist in the design category. The other categories are performance car, urban car, electric vehicle and luxury model. Each category has five finalists except World Car, which has 10. One brand conspicuous by its absence in any category: Tesla. The winner in each is scheduled to be crowned March 27 at the New York International Auto Show in Manhattan. This year marks the 20th year of the World Car Awards and the partnership with the New York show. The selection process involves 100-plus automotive journalists from 29 countries who vote, as they review and test-drive the eligible vehicles for the 2024 awards. Their journey is captured virtually on World Car TV. If youÂ’re counting, the brands that appear most on the six finals lists are Mercedes-Benz (four times), BMW (also four), Hyundai (three), and Volvo (three). HereÂ’s the full listing. A video clip showing all of them is here: World Car -BYD Seal / Atto 4 -Ford Bronco -Hyundai Kona / Kona Electric -Hyundai Santa Fe -Kia EV9 -Mazda CX-90 -Subaru Crosstrek -Toyota Prius -Volkswagen ID.7 -Volvo EX30 World Car Design of the Year Ford Bronco Ferrari Purosangue Toyota Prius Volvo EX30 Zeekr X 2024 World Electric Vehicle BMW i5 Kia EV9 Mercedes-Benz EQE SUV Volkswagen ID.7 Volvo EX30 2024 World Luxury Car - BMW 5 Series / i5 - Lexus LM - Mercedes-Benz CLE - Mercedes-Benz E-Class - Mercedes-Benz EQE SUV 2024 World Urban Car - Abarth 500e - BYD Dolphin - Lexus LBX - Suzuki Fronx - Volvo EX30 2024 World Performance Car - BMW M2 - BMW XM - Ferrari Purosangue - Hyundai Ioniq 5 N - Porsche Cayenne Turbo E-Hybrid

Toyota, Mazda form electric car technology venture

Thu, Sep 28 2017TOKYO — Toyota has established a new venture to develop electric vehicle technology with partner Mazda, seeking to catch up with rivals in an increasingly frenetic race to produce more battery-powered cars. Policymakers in key markets like China are pushing a shift to electric cars over the next two to three decades, while relatively new rival Tesla is gaining momentum and diesel cars are going through the fallout of the Volkswagen diesel scandal, pressuring traditional automakers to crank up plans for fully electric vehicles (EVs). At the same time, declining battery costs are enabling more power to be packed into cars, making an electric car future easier to imagine. Toyota said in a statement the new company will develop technology for a range of electric cars, including mini vehicles, passenger cars, SUVs and light trucks. Toyota will take a 90 percent stake in the joint venture, called EV Common Architecture Spirit Co Ltd, while Mazda and Denso Corp, Toyota's biggest supplier, will each take 5 percent. The plans build on a partnership announced in August when Japan's biggest automaker agreed to take a 5 percent stake in Mazda and two said they would jointly develop affordable electric vehicle technologies. Although Toyota is providing most of the financial firepower and existing EV know-how, Mazda's engineers have gained the admiration of the industry with breakthrough technologies such as its compression ignition engine announced last month. Shares in Mazda surged to end the day 3 percent higher, while those in Denso rose 1.8 percent. Toyota shares were flat. Both automakers are somewhat behind rivals, with neither having a fully electric passenger car on the market yet. After years of focusing on bringing hydrogen fuel cell vehicles to the market, Toyota last year set up a division to develop electric cars which is led by President Akio Toyoda, and said it plans to introduce EVs in China in the coming years. Toyota has also announced it will bring a game-changing solid-state EV battery to market by 2022. That division would continue as a separate entity from the new joint venture, a Toyota spokeswoman said, while adding that the two teams would co-operate on technology development. Mazda has an R&D budget a fraction of Toyota's, which has made it difficult to develop electric cars on its own. Even so, it has said it plans to launch EVs in 2020.