1981 Toyota Corolla 5 Speed Weber Carb on 2040-cars

La Fayette, Georgia, United States

Body Type:Sedan

Engine:1.8L 1770CC l4 GAS OHV Naturally Aspirated

Fuel Type:Gasoline

For Sale By:Private Seller

Vehicle Title:Clear

Number of Cylinders: 4

Make: Toyota

Model: Corolla

Trim: DLX Sedan 4-Door

Options: Cassette Player, Leather Seats

Power Options: Air Conditioning

Drive Type: RWD

Mileage: 50,281

Exterior Color: Brown

Disability Equipped: No

Interior Color: Tan

Overall this car is in great shape. I found this car in front of a shop in a town near mine, bought it, and began to fix it. Since then I've had the gas tank lined and a new Weber 32/36 carburetor installed. I also did a basic tune up: plugs, oil change, etc. It runs and drives great and surprisingly the air compressor works great and the air is cold. There are only two complaints you could have and those are the driver's seats wear and the tire's condition. Comes with a GA tag receipt and bill of sale only. Message me with any of the questions you have and I will be happy to answer.

Thanks

Toyota Corolla for Sale

No reserve 2003 toyota corolla s 4dr auto ps pb pw pl cc ac alloy rims new tires

No reserve 2003 toyota corolla s 4dr auto ps pb pw pl cc ac alloy rims new tires 1987 toyota corolla fx16 gt-s -- 5 speed -- gts -- 139k miles(US $4,000.00)

1987 toyota corolla fx16 gt-s -- 5 speed -- gts -- 139k miles(US $4,000.00) 2006 s 1.8l auto white(US $9,995.00)

2006 s 1.8l auto white(US $9,995.00) 2005 toyota corolla

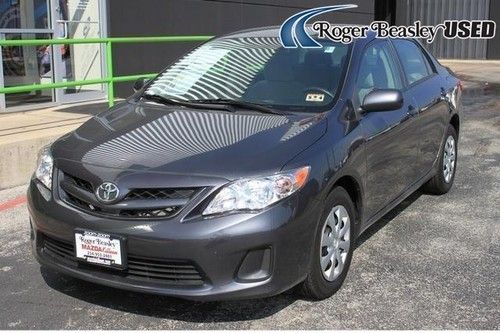

2005 toyota corolla 2011 toyota corolla le gray 4-speed automatic low miles aux mp3 input(US $13,499.00)

2011 toyota corolla le gray 4-speed automatic low miles aux mp3 input(US $13,499.00) 2011 s used 1.8l i4 16v manual front wheel drive sedan low reserve financing

2011 s used 1.8l i4 16v manual front wheel drive sedan low reserve financing

Auto Services in Georgia

Zoro Used Auto Sales ★★★★★

Xtreme Wheels & Tires ★★★★★

Whitleys Garage ★★★★★

Westside Service Center ★★★★★

Wesley`s Car Care & Detail ★★★★★

Valdosta Alignment Co ★★★★★

Auto blog

HyFive hydrogen infrastructure gets $51M boost across Europe

Fri, Apr 4 2014"High five!" was one of the catch-phrases of Sacha Baron Cohen's Kazakh comedic alter ego Borat. A real-world HyFive is being announced by a power broker named Boris. And this is serious business. London Mayor Boris Johnson has announced a program called HyFive, which will see automakers and other entities invest 31 million British pounds ($51 million US) in a demonstration project for hydrogen fuel-cell vehicles. By next year, London will have three hydrogen refueling stations, while there will be one each in the Danish cities of Aarhus and Odense and one in Innsbruck, Austria. Leaders of the program are planning for other stations in Sweden, Germany and Italy. The five participating automakers are BMW, Mercedes-Benz parent Daimler, Honda, Hyundai and Toyota, while other companies involved include Copenhagen Hydrogen Network, ITM Power and Linde. Those OEMs will make 110 fuel-cell vehicles available for deployment in Bolzano, Copenhagen, Innsbruck, London, Munich and Stuttgart. The program represents an effort to address the "chicken or egg?" challenge inherent to establishing a hydrogen fuel cell vehicle market. While the powertrain technology provides benefits by combining fossil-fuel-like refueling times with long driving ranges and zero emissions, establishing a refueling network and building fuel-cell vehicles is prohibitively expensive, especially in low volumes. The London mayor is no stranger to green transportation technology. Late last year, Johnson made himself available for a photo opportunity with Ecotive and Frazer-Nash, which had developed a six-passenger extended-range plug-in taxicab. The mayor got a test drive in the cabs this week. You can check out the HyFive press release below. Global leaders sign up to GBP31m plan to demonstrate viability of hydrogen vehicles International project HyFive pioneers hydrogen fuel cell technology A pioneering GBP31 million deal will be struck today (3 April) to make hydrogen vehicles a viable and environmentally friendly choice for motorists across Europe. Leading motor manufacturers, hydrogen fuel suppliers, the Mayor of London's Office and energy consultancies from around the globe are signing up to the HyFive project, the largest of its kind in Europe, at City Hall in London today.

An early gas-electric hybrid was developed by...Exxon?

Tue, Oct 25 2016We're not sure which aspect of Exxon's 1970s-era efforts to develop advanced and electrified powertrains is the most ironic. There's Exxon, that of the Valdez oil spill infamy, being on the leading edge of hybrids and electric vehicles. There's a boat-like Chrysler Cordova getting 27 miles per gallon. And there's the central role a Volkswagen diesel engine plays in that hybrid development. It's all outlined in an article (linked above) by Inside Climate News, and it's an amusing read. Flush with cash and fearing what it thought was peak oil production in the 1970s, Exxon funded a host of new ventures divisions geared to find alternatives to gas-powered powertrains. In the early 1970s, Exxon lured chemist M. Stanley Whittingham to develop what would become a prototype of a lithium-ion rechargeable battery. Then, in the late 1970s, Exxon pioneered the concept of using an alternating-current (AC) motor as part of a gas-electric hybrid vehicle. The company retrofitted a Chrysler Cordova (yes, that's the model Ricardo Montalban used to hawk) with a powertrain that combined 10 Sears Die-Hard car batteries, an alternating current synthesizer (ACS), a 100-horsepower AC motor, and, yes, a four-cylinder 50-horsepower Volkswagen diesel engine. The result was a rather large two-door sedan that got an impressive 27 mpg. And while US automakers didn't see the potential in the early concept, in 1980 Exxon and Toyota began collaborating on a project that would involve retrofitting a Toyota Cressida with a hybrid engine. That car was completed in 1981, and may have been one of the seeds that eventually helped sprout the concept of the Toyota Prius. Soon after rebuilding the Cressida, Exxon would get out of the advanced-powertrain-development business, as oil prices began to fall in the early 1980s, spurring cost-cutting measures. Cry no tears for the Exxon, though, as what's now known as ExxonMobil is the largest US oil company. Related Video: News Source: Inside Climate NewsImage Credit: Spencer Platt/Getty Images Green Read This Chrysler Toyota Electric Hybrid battery

Toyota makes $100M investment to boost Indiana Highlander production

Mon, 25 Aug 2014Toyota has announced that it will be making a $100 million investment in its Princeton, IN factory in a bid to increase production of its popular Highlander CUV. The move will create 300 new jobs by 2016 and increase the total number of crossovers the plant can produce by 30,000.

Toyota currently builds the Highlander, alongside the fullsize Sequoia, at Toyota Indiana's West Plant. The additional capacity, though, will be sent to the East Plant, which is currently responsible for production of the recently refreshed Sienna minivan.

"The Highlander has been a great product for our plant," Toyota Indiana President Norm Bafunno said in a statement. "Establishing Highlander as the 'bridge vehicle,' as we call it, between the East and West plants increases our ability to meet customer needs for our outstanding products. This exciting news is a true testament to the capability of our hard-working and dedicated team members."