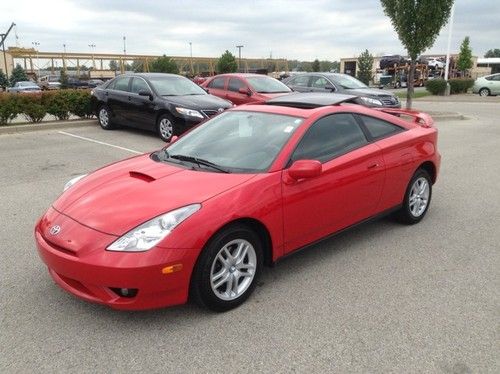

2003 Toyota Celica Gt on 2040-cars

Avon, Indiana, United States

Vehicle Title:Clear

Engine:1.8L 1794CC l4 GAS DOHC Naturally Aspirated

Fuel Type:GAS

Transmission:Manual

Make: Toyota

Warranty: Vehicle does NOT have an existing warranty

Model: Celica

Trim: GT Hatchback 2-Door

Options: Sunroof, Cassette Player, CD Player

Power Options: Air Conditioning, Cruise Control, Power Locks, Power Windows

Drive Type: FWD

Mileage: 78,337

Disability Equipped: No

Exterior Color: Red

Number of doors: 3

Interior Color: Black

Series: GT

Number of Cylinders: 4

Certification: None

Drivetrain: FWD

Toyota Celica for Sale

2001 toyota celica gt hatchback 2-door 1.8l

2001 toyota celica gt hatchback 2-door 1.8l 1999 toyota celica gt - low mileage - excellent condition!(US $8,600.00)

1999 toyota celica gt - low mileage - excellent condition!(US $8,600.00) 1988 toyota celica all trac hatchback 2-door 2.0l turbo awd 3sgte(US $4,500.00)

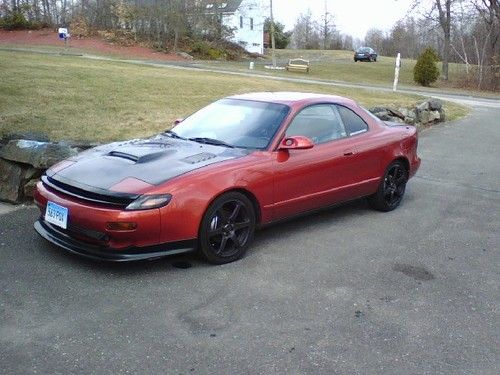

1988 toyota celica all trac hatchback 2-door 2.0l turbo awd 3sgte(US $4,500.00) 1990 toyota celica gt2 coupe 2-door with 3sgte engine(US $6,300.00)

1990 toyota celica gt2 coupe 2-door with 3sgte engine(US $6,300.00) 1994 toyota celica gt hatchback 2-door 2.2l

1994 toyota celica gt hatchback 2-door 2.2l 75k engine & 135k transmission! newer top!(US $3,500.00)

75k engine & 135k transmission! newer top!(US $3,500.00)

Auto Services in Indiana

Williams Auto Parts Inc ★★★★★

Wes`s Wheels & Tires ★★★★★

Tsi Auto Repair & Service ★★★★★

Town & Country Ford Inc ★★★★★

Tachyon Performance ★★★★★

Stroud Auto ★★★★★

Auto blog

Toyota will retrofit late-model cars with new technology

Fri, Jan 7 2022Toyota will inaugurate a service called Kinto Factory that will add modern features like electronic driving aids to select late-model cars. The program will launch in Japan in January 2022, and it aims to let motorists benefit from new technology without having to buy a new car. Kinto Factory will initially offer customers two basic services: upgrading and remodeling. Upgrading is defined as retrofitting safety and convenience functions, like emergency braking assist, a blind spot monitoring system with rear cross-traffic alert, and a hands-free tailgate or trunk lid. Remodeling involves replacing worn or damaged parts inside and out, such as the upholstery, the seat cushions, and the steering wheel. Personalization will join the list of services at a later date, partly because it involves gathering data on how drivers use their car. The list of cars eligible to receive a makeover from Kinto Factory include the Prius, the Prius c (which is called Aqua in Japan), the Prius V (known as the Prius ? in its home country), the Lexus UX (pictured), and the Lexus NX. Since the program is launching in Japan, Kinto Factory will also work on vehicles we've never seen on American roads, like the Vellfire (a big minivan) and its upscale Alphard derivative. Pricing information and availability will be announced closer to the program's launch. Toyota notes that each upgrade will be available individually, so customers will be able to select precisely what's added to their car, and that all of the parts will be backed by a warranty. As of writing, Toyota hasn't announced plans to bring the Kinto Factory program to the United States. However, it added that the upgrades detailed above represent the program's first step, and it clarified that it's open to the idea of expanding the service in overseas markets.

Toyota updates Euro-market GT86 suspension, appearance

Thu, 24 Apr 2014While we were busy ogling the Scion FR-S Release Series 1.0 with its Yuzu yellow paint and a workover by Toyota Racing Development, and the Japanese Toyota 86 buyers were trying out their Playstation-compatible Sports Drive Logger telemetry system, the European 2015 Toyota GT86 got fitted with some new parts of its own. New on next year's model are stiffer mounts for the front suspension and rear shock absorbers, and new shocks in the back for better damping and less friction. Toyota says the result is sharper steering and less body roll.

Inside, the instrument panel and center console get decorated with a "carbon-fiber motif." There are new shades of pearl white and silver to dress up the outside, and the roof gets a shark-fin antenna for sharper looks and aero. It goes on sale this summer, and you can read everything we just told you in the press release below. We've reached out to Scion to see if we'll get the same upgrades on the FR-S this summer, too, company PR rep Nancy Hubbell telling us, "The European changes are among those being considered for the US model FR-S and we'll have final confirmation soon."

2014 Toyota Tundra Platinum 4x4

Wed, 26 Feb 2014The Toyota Tundra is the automotive version of off-brand Cheerios: it doesn't dominate the market, and it's not the first model people think of when they hear the term "pickup truck."

Ford, General Motors and Ram dominate the segment with vehicles that offer ridiculous levels of towing and payload capacities and models loaded with luxury items and primed with tech-rich engines. The off-brands, meanwhile, are led by the Tundra, which while still accounting for six-figure sales (112,732 units in 2013, up from 101,621 in 2012), sits well behind the F-150s and Silverados of the world. After our first drive of the revamped 2014 Tundra, we came away thinking this truck is a total underachiever, aimed at placating Toyota loyalists and doing little to win over new customers.

But everybody deserves a second chance, and we thought a week's drive in a different environment might lead to a different - or at least a more fully realized - opinion. While the Tundra might not be an industry leader, it still makes it on many truck buyers' shopping lists. So, should you consider this off-brand pickup truck? To find out, we borrowed a top-of-the-line Tundra Platinum for a week. Read on to see what we found.