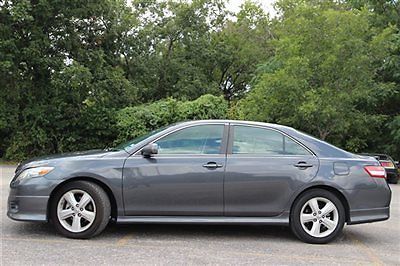

2003 Toyota Camry Xle Sedan 4-door 2.4l on 2040-cars

East Brunswick, New Jersey, United States

Body Type:Sedan

Fuel Type:GAS

Engine:2.4L 2362CC l4 GAS DOHC Naturally Aspirated

Vehicle Title:Clear

Used

Year: 2003

Number of Cylinders: 4

Make: Toyota

Model: Camry

Trim: XLE Sedan 4-Door

Mileage: 96,000

Drive Type: FWD

|

for sale $8000

|

Toyota Camry for Sale

2006 toyota camry le sedan 4-door 2.4l(US $4,800.00)

2006 toyota camry le sedan 4-door 2.4l(US $4,800.00) 2011 toyota camry le sedan 4-door 2.5l(US $16,000.00)

2011 toyota camry le sedan 4-door 2.5l(US $16,000.00) 2014 toyota camry se paddle shift ground effects 28k mi texas direct auto(US $17,980.00)

2014 toyota camry se paddle shift ground effects 28k mi texas direct auto(US $17,980.00) Toyota camry base se 4 dr sedan automatic gasoline 2.5l 4 cyl magnetic gray meta(US $12,688.00)

Toyota camry base se 4 dr sedan automatic gasoline 2.5l 4 cyl magnetic gray meta(US $12,688.00) 2008 le silver 4-dr automatic front-wheel drive sedan — low miles — 2nd owner(US $12,995.00)

2008 le silver 4-dr automatic front-wheel drive sedan — low miles — 2nd owner(US $12,995.00) 4dr sedan automatic 2.4l dohc vvt-i 16-valve silver

4dr sedan automatic 2.4l dohc vvt-i 16-valve silver

Auto Services in New Jersey

Vip Honda ★★★★★

Totowa Auto Works ★★★★★

Taylors Auto And Collision ★★★★★

Sunoco Auto Care ★★★★★

SR Recycling Inc ★★★★★

Robertiello`s Auto Body Works ★★★★★

Auto blog

Lexus NX, BMW i3 to get Super Bowl commercials

Mon, Jan 19 2015At this point last year, we'd been getting news on automotive-focused Super Bowl commercials for more than two months. The teasers hadn't come out yet, but manufacturers lined up for the super-expensive spots were making their intentions known. This year? Almost nada, until this week. BMW has said it will air a 60-second spot promoting the i3 during the first quarter of the game, the Munich firm returning to The Big Game after a four-year absence. BMW says, "Big ideas like the BMW i3 take a little getting used to, and the creative idea surrounding our spot will play on this analogy." We say that pitching a tiny range-extended hatchback during the beer-iest American sports orgy of the year should make for some neat commentary afterward. Lexus is putting its new NX crossover in the second Super Bowl commercial it's ever aired, eschewing the glitter of celebrities and glamor for a straight-shooting spot and the tagline, "Be seen, be heard, make some noise." Joining those two are Kia, Mercedes-Benz, Nissan and Toyota. The six confirmed carmakers are down from eleven last year, when car spots made up a quarter of the total ad time. The price to do business for 30 seconds this year: reportedly around $4.5 million, up a stacks from last year's $4 million. You can watch the Lexus commercial in the video above, and beneath that, the BMW press release below has a bit more information on its effort. BMW to Advertise All-Electric BMW i3 during Super Bowl XLIX. The all-electric BMW i3 is featured in a 60-second spot during Super Bowl XLIX on Sunday, February 1, 2015. Woodcliff Lake, NJ – January 15, 2015... Today, BMW announced plans to feature the all-electric BMW i3 in a 60-second spot during Super Bowl XLIX on Sunday, February 1, 2015. After a 4-year hiatus, BMW will be returning to the big game with a commercial during the first quarter. "As one in three Americans will tune in to watch the Super Bowl, we are thrilled to use this platform to educate viewers on the importance of electric mobility," said Trudy Hardy, Vice President of Marketing, BMW of North America. "Big ideas like the BMW i3 take a little getting used to, and the creative idea surrounding our spot will play on this analogy." BMW i is BMW's forward-looking and sustainable brand dedicated to solving many of the mobility challenges faced by the world's most densely populated cities. The BMW i3 is the first of the BMW i vehicles constructed from the ground up primarily of carbon fiber.

Toyota Camry incentives and fleet sales cranked to keep sales crown, insiders worried

Mon, 01 Jul 2013We've been watching for some time now as Toyota has piled more incentives on the hood of its Camry sedan, and Automotive News reports that the we're not the only ones with raised eyebrows. The current Camry hasn't even been on the market for two years, but the family sedan segment is more hotly contested than it has been in years. It's that high level of competition that has led the automaker to uncharacteristically add more money on the hood in order to assure it maintains its long-held title of America's Best-Selling Car, a mantle it has owned for a dozen years. It's ramping up fleet sales, too.

According to the analysts at TrueCar, Toyota has bumped incentives per unit every month this year, now totaling some $2,750 as of May, a 38-percent hike over this time last year. That's more spiff money than the segment's other best sellers, the Nissan Altima ($2,400), Ford Fusion ($2,300) and Honda Accord ($1,400), all of whom have actually decreased their incentive spend by 20- to 40-percent over the same period.

The ramp up in incentive spending and fleet sales has analysts concerned that Toyota will tarnish the Camry's historically sterling resale value. ALG pegs the 2013 Camry's current 36-month residual value at 54.4 percent, well ahead of the segment average's 50.9 percent (but shy of the Accord's 55.6 percent). However, analysts are concerned that as the current generation ages, their resale values will eventually plummet if incentives continue to increase as Toyota looks to keep the Camry's best-selling car crown going forward.

Ryan Tuerck's Ferrari-powered Gumout GT4586 debuts at SEMA

Wed, Nov 2 2016Las Vegas is famous for its shotgun marriages, but the only Sin City nuptials we're interested in is the one officiated by Ryan Tuerck between a Toyota GT86 and the V8 engine from a Ferrari 458 Italia. The insane Gumout GT4586, as it's called, is probably one of the most well-known of the 2016 SEMA Show's stars, after video popped up showing the rear-drive Frankenstein firing up and spitting flames through its weird, front-mounted exhausts. The day after we published that video, which showed the GT86 in mostly bare frame, Gumout and Tuerck posted a second clip showing the Japanese-Italian coupe literally running rings around a 458 while wearing its sheetmetal and yellow-tinted headlights. The car's look in that second video carried over to the Las Vegas Convention Center floor, where the GT4586 showed up sans hood, ludicrously wide tires, and a huge wing and rear diffuser. It's clearly a good-looking car. You can check out our full SEMA gallery above, or, click the video below for a second look at Tuerck's Ferra-yota in action below. This content is hosted by a third party. To view it, please update your privacy preferences. Manage Settings.

2040Cars.com © 2012-2025. All Rights Reserved.

Designated trademarks and brands are the property of their respective owners.

Use of this Web site constitutes acceptance of the 2040Cars User Agreement and Privacy Policy.

0.053 s, 7923 u