2001 Toyota Avalon Xls on 2040-cars

Brooklyn, New York, United States

|

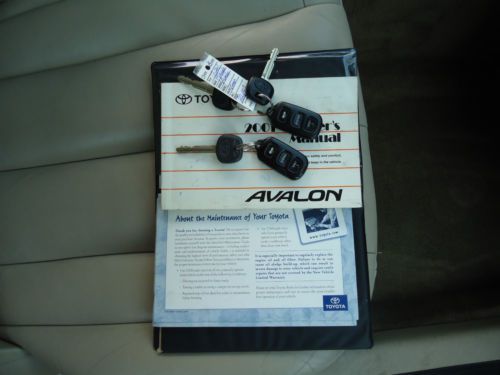

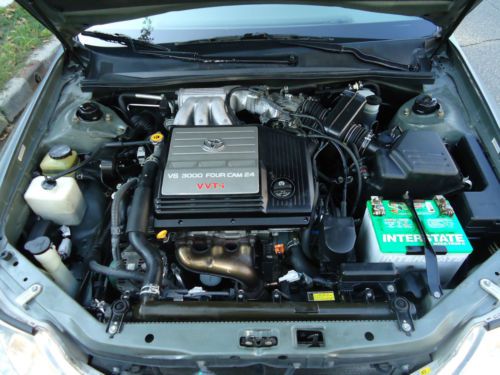

2001 TOYOTA AVALON XLS ONLY 109300 MILES. Automatic transmission,sunroof,heated front seats,cold air,books,3keys,very good tires,has some dents and scratches. We accept payment via Pay Pal (deposit only),bank check,cash for remaining balance. Deposit of $ 500 is due within 24 hours of auction close. For any question call 347-766-3931 |

Toyota Avalon for Sale

2004 toyota avalon xl sedan 4-door 3.0l

2004 toyota avalon xl sedan 4-door 3.0l Toyota avalon 2004, low mileage(US $10,750.00)

Toyota avalon 2004, low mileage(US $10,750.00) 4dr sdn xl toyota avalon xl low miles sedan automatic gasoline 3.5l dohc efi 24-

4dr sdn xl toyota avalon xl low miles sedan automatic gasoline 3.5l dohc efi 24- Very clean 2007 toyota avalon limited fully loaded navigation

Very clean 2007 toyota avalon limited fully loaded navigation 2002 toyota avalon xls sedan 4-door 3.0l(US $7,250.00)

2002 toyota avalon xls sedan 4-door 3.0l(US $7,250.00) 2014 toyota avalon xle 3.5l v6 leather w/ heated seats bluetooth camera sirius(US $26,983.00)

2014 toyota avalon xle 3.5l v6 leather w/ heated seats bluetooth camera sirius(US $26,983.00)

Auto Services in New York

Zuniga Upholstery ★★★★★

Westbury Nissan ★★★★★

Valvoline Instant Oil Change ★★★★★

Valvoline Instant Oil Change ★★★★★

Value Auto Sales Inc ★★★★★

TM & T Tire ★★★★★

Auto blog

Japanese earthquakes send ripples through auto industry

Mon, Apr 18 2016The earthquakes since April 14 in Japan's Kumamoto Prefecture on the island of Kyushu are having aftershocks on the US auto industry, particularly for Toyota. The company shut down most of its factories in the country due to parts shortages, and the plants will be closed at least through April 23. "Decisions regarding recommencement of operation at plants in Japan will be made on the basis of availability of parts," the company said in a statement. According to Automotive News, Toyota's closed factories include a vast range of popular models in the US, including the Toyota Prius, Mirai, RAV4, 4Runner, Land Cruiser, Lexus ES, LS, IS, GS, RC, NX, RX, GX, and LX. The company's only sites in Japan that are still open build Hino trucks, Daihatsu models, and the Toyota Century limo. Toyota isn't yet sure whether these shutdowns could lead to vehicle shortages in the US. "As you can imagine, we are still reviewing the situation and working to learn more," company spokesperson Aaron Fowles told Autoblog. "While we know that production will be suspended in stages at most of our vehicle assembly facilities in Japan between April 18th and the 23rd, we do not know if they will continue production suspensions. Also, any effects to our inventory and/or sales have yet to be determined." He expects the automaker to know more in the coming days. Many of the affected Toyota plants aren't even in Kumamoto Prefecture, but major suppliers have factories in the region. For example, Aisin Seiki and Renesas Electronics both had to shutdown operations at plants in the area, according to Automotive News. Toyota isn't the only automaker affected. Nissan experienced a brief slowdown but was back to work on Monday, and Honda has suspended a motorcycle plant in the region until Friday. Mitsubishi had to close a production line due to the parts shortage, according to The Japan Times, but it didn't affect US models. "A supplier to our Mizushima plant has been impacted but they only supply an engine part for our mini car line. That line has been temporarily shut down due to that situation," spokesperson Alex Fedorak told Autoblog. "That same plant builds the Lancer and i-MiEv and there has been no impact to that line and production continues uninterrupted." Two major quakes hit Kumamoto Prefecture around Kumamoto city in the past week. The first on April 14 measured 6.4 magnitude, and a second on April 16 measured 7.3.

Toyota retires robots in favor of humans to improve automaking process

Sat, 12 Apr 2014Mitsuru Kawai is overseeing a return to the old ways at Toyota factories throughout Japan. Having spent 50 years at the Japanese automaker, Kawai remembers when manual skills were prized at the company and "experienced masters used to be called gods, and they could make anything." Company CEO Akio Toyoda personally chose Kawai to develop programs to teach workers metalcraft such as how to forge a crankshaft from scratch, and 100 workstations that formerly housed machines have been set aside for human training.

The idea is that when employees personally understand the fabrication of components, they will understand how to make better machines. Said Kawai, "To be the master of the machine, you have to have the knowledge and the skills to teach the machine." Lessons learned by the newly skilled workers have led to shorter production lines - in one case, 96percent shorter - improved parts production and less scrap.

Taking time to give workers the knowledge to solve problems instead of merely having them "feed parts into a machine and call somebody for help when it breaks down," Kawai's initiative is akin to that of Toyota's Operations Management Consulting Division, where new managers are given a length of time to finish a project but not given any help - they have to learn on their own. It's not a step back from Toyota's quest to build more than ten million cars a year; it's an effort to make sure that this time they don't sacrifice quality while making the effort. Said Kawai, "We need to become more solid and get back to basics."

Recharge Wrap-up: BMW plans for retired batteries; automakers support dual-standard chargers

Sun, Feb 1 2015Toyota will test hybrids with silicon-carbide (SiC) power semiconductors. In Japan, Toyota has put the SiC power semiconductors into the power control units of a Camry Hybrid prototype and a fuel cell bus for a year-long test. Research suggests the SiC units will decrease electrical losses while managing power supply, thus improving overall powertrain efficiency. Current power semiconductors account for about 20 percent of electrical losses, and success with these tests could mean more efficient hybrids on the roads in the future. Read more at Hybrid Cars. Automakers from CCS and CHAdeMO camps are supporting dual-standard charging station networks. https://www.autoblog.com/bmw/, Volkswagen (CCS camp) and ChargePoint announced plans to build "express charging corridors" by installing about 100 DC fast chargers, many of which will support both types of charging. Kansas City Power & Light is partnering with Nissan (CHAdeMO camp) and ChargePoint to install DC chargers that "will charge any model of electric vehicle on the market." This leads the folks at Green Car Reports to look into whether this ends the looming standard war between automakers in the US. Read more at Green Car Reports. BMW, Bosch and utility company Vattenfall are making plans for a second life for retired BMW i3 batteries. The Second Life Batteries Alliance project will recycle the old lithium ion battery packs - which can still hold a charge - in off-grid storage and grid-stabilization applications, beginning with a grid storage system in Hamburg, Germany. Bosch has created a battery management algorithm to extend the life of the batteries and make sure they don't cause harm to Vattenfall's facilities. Read more at Transport Evolved.