2000 Xl (4dr Sdn Xl W/bucket Seats) Used 3l V6 24v Automatic Front-wheel Drive on 2040-cars

Garland, Texas, United States

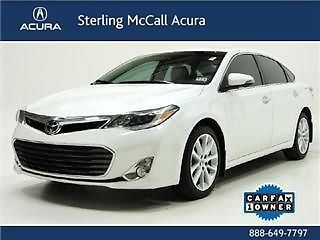

Toyota Avalon for Sale

Toyota avalon 2001, $3991!!!

Toyota avalon 2001, $3991!!! Xls 3.0l clean carfax low miles smoke free excellent condition garage kept

Xls 3.0l clean carfax low miles smoke free excellent condition garage kept 2013 toyota avalon xle gorgeous color super low miles!!! just like new!(US $29,000.00)

2013 toyota avalon xle gorgeous color super low miles!!! just like new!(US $29,000.00) 2003 toyota avalon xl sedan 4-door 3.0l(US $6,900.00)

2003 toyota avalon xl sedan 4-door 3.0l(US $6,900.00) 2000 toyota avalo xls one owner low miles(US $5,500.00)

2000 toyota avalo xls one owner low miles(US $5,500.00) 2013 toyota avalon sdn limited heated ventilated leather navi back cam sunroof(US $32,988.00)

2013 toyota avalon sdn limited heated ventilated leather navi back cam sunroof(US $32,988.00)

Auto Services in Texas

Wynn`s Automotive Service ★★★★★

Westside Trim & Glass ★★★★★

Wash Me Car Salon ★★★★★

Vernon & Fletcher Automotive ★★★★★

Vehicle Inspections By Mogo ★★★★★

Two Brothers Auto Body ★★★★★

Auto blog

Japanese automakers welcome North American trade deal, fear what's next

Tue, Oct 2 2018TOKYO — Toyota, Nissan and Mazda welcomed on Tuesday the revised North America trade deal that left Japanese automakers unscathed, but they may face a bumpy ride when Washington and Tokyo hold new talks on over $40 billion of annual U.S. auto imports from Japan. The United States and Canada reached an agreement on Sunday to update the 1994 North American Free Trade Agreement after Washington had forged a separate trade deal with Mexico in August. The updated deal effectively maintains the auto industry's current footprint in North America, and spares Canada and Mexico from the prospect of U.S. national security tariffs on their vehicles. Mazda, which ships cars to the United States from Mexico and Japan, called the deal a "big step forward". Nissan, which makes the cars it sells in the United States locally as well as in Mexico, Japan and other countries, said it was "encouraged" by the agreement. Toyota, Japan's biggest automaker, said it was "pleased" that a basic deal was reached. Other automakers were not immediately available for comment. While the deal has removed the risk that the disintegration of the pact would have posed to automakers, bigger risks loom large for Japanese firms as a chunk of the roughly 7 million cars they sold in the U.S. last year were shipped from Japan, and a trade deal between Washington and Tokyo has yet to be agreed. The United States and Japan last week agreed to begin fresh trade talks, with U.S. President Donald Trump seeking to address Japan's $69 billion trade surplus, of which nearly two-thirds comes from auto exports. Washington is also investigating the possibility of slapping 25 percent tariffs on auto imports on national security grounds, although it has agreed with Japan to put any new tariffs on hold during the talks. Analysts say the United States may take a tougher stance on auto imports from Japan than from its neighbors. "If Japan requests an exemption from the 25 percent tariffs under consideration, Washington could propose a more strict cap on imports than it agreed to with Mexico and Canada," said Koji Endo, senior analyst at SBI Securities. "That would be a risk." This could be a big blow to Japan, as the United States is a key source of revenue for Japanese automakers including Toyota, Nissan and Honda. The U.S. market accounts for a quarter or more of their annual global vehicle sales, and of their total U.S.

Illinois’ pro-union stance kills bid for Toyota-Mazda plant, report says

Thu, Oct 19 2017Mazda and Toyota are fielding bids from states eager to land its new prize: an all-new $1.6 billion U.S. plant where the Japanese automakers would jointly build electric vehicles and employ around 4,000 workers. Now we can apparently scratch Illinois off the list of contenders. According to Automotive News, the Land of Lincoln has been disqualified due to a lack of shovel-ready sites and the state's lack of a right-to-work law curtailing union membership. Mark Peterson, the president and CEO of economic development agency Intersect Illinois, told the publication he's been informed Illinois is not among the three or four finalists for the facility. It's believed those finalists are all in the South. Peterson said that "many national site consultants charged with making recommendations for corporate relocations and expansions will not even consider a state that is not a right-to-work state. In this case, the three states I am told are still in the running are all right-to-work states." The Midwest may be the ancestral home of U.S. automotive manufacturing, but the South has made major inroads in recent decades, with the likes of Honda, Mercedes-Benz, Nissan and Toyota all opening plants there, among others, thanks to lucrative tax incentives and the absence of labor unions. Recent years have also seen so-called right-to-work laws, which prohibit union dues and membership as a condition of employment in organized workplaces, spread to traditional labor strongholds such as Michigan and Wisconsin. The new joint venture plant, which would start operating in 2021, would be capable of producing 300,000 vehicles a year, with production divided between the two automakers. Mazda and Toyota would also take small stakes in one another as part of the deal. It's expected that at least 15 states have submitted proposals to attract the plant. Expect the Illinois news to trigger a new round of debate over the role of organized labor in the modern economy.Related Video: Image Credit: Reuters Green Plants/Manufacturing Mazda Toyota

Jaguar solution to keyless start could save lives

Mon, May 14 2018UPDATED: An earlier version of this story indicated the Jaguar keyless start function was meant as a safety feature, when in fact, it is meant as a convenience one and will not work as described if automatic stop/start is not engaged. Today, The New York Times published an article about more than two dozen deaths related to drivers accidentally leaving their cars running, closing their garages and later succumbing to carbon monoxide that flooded their homes. The reason has been identified as "keyless start" features, or proximity entry and push-button start, where owners don't need to physically handle a key or fob to gain entry into the vehicle or start it. It is the latest, and deadliest, issue raised with this system after those related to security and simple inconvenience (for instance, leaving the car at a valet or car wash with the fob in your pocket). From my personal perspective, The New York Times had a rather harsh "evil carmakers" tone throughout the article. This is not a matter of a known faulty component, as with the GM ignition switch recall. This has as much to do with user error where people leave their car without pressing the "off" button and without noticing the engine is still running. About half of the cars in question are produced by Toyota and Lexus, brands that have offered keyless start longer than most. They are also brands with high rates of elderly owners, who seemingly made up a majority of reported deaths and injuries. One fire department in Florida even started a campaign alerting those in the area of the dangers of leaving your car running when it noticed a correlation between an increase in cars equipped with keyless start and calls related to carbon monoxide poisoning. I see several contributing issues at play, most of which go well beyond this particular issue. First is insufficient training of owners by dealers and/or owners not paying close enough attention during this training. Cars are complicated, but you should at least know how basic functions work. Second, woefully inadequate driver training in this country. Third, and with apologies to the AARP, insufficient testing of elderly drivers and/or insufficiently low standards for elderly drivers. If you don't know you have to shut the car off or cannot hear that an engine is running, perhaps you shouldn't be driving. Fourth, re-examining keyless start systems.