Sr5 Certified Suv 4.0l Cd 8 Speakers Am/fm Radio Mp3 Decoder Air Conditioning on 2040-cars

Brook Park, Ohio, United States

Toyota 4Runner for Sale

2003 gray limited*roof*4x4*v8*lthr*the best!!!

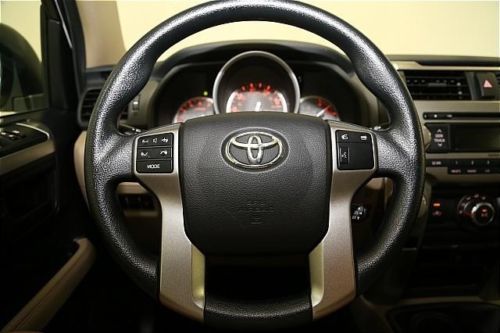

2003 gray limited*roof*4x4*v8*lthr*the best!!! 2010 toyota 4runner sr5 one owner sunroof power pkg cruise control clean suv(US $24,370.00)

2010 toyota 4runner sr5 one owner sunroof power pkg cruise control clean suv(US $24,370.00) 2003 limited v8 (a5) used 4.7l v8 32v automatic 4x2 suv(US $10,991.00)

2003 limited v8 (a5) used 4.7l v8 32v automatic 4x2 suv(US $10,991.00) 2011 toyota 4runner 4x4 v6 leather alloy wheels all power

2011 toyota 4runner 4x4 v6 leather alloy wheels all power Air texas moon roof gray cloth interior auto control power black roof rack(US $15,988.00)

Air texas moon roof gray cloth interior auto control power black roof rack(US $15,988.00) 2004 toyota 4 runner sport edition 4-door, 4wd, v8, 1 owner, galactic gray(US $17,500.00)

2004 toyota 4 runner sport edition 4-door, 4wd, v8, 1 owner, galactic gray(US $17,500.00)

Auto Services in Ohio

Zerolift ★★★★★

Worthington Towing & Auto Care Inc ★★★★★

Why Pay More Motors ★★★★★

Wayne`s Auto Repair ★★★★★

Walt`s Auto Inc ★★★★★

Voss Collision Centre ★★★★★

Auto blog

Tougher than steel: Wood pulp could make lighter auto parts

Tue, Aug 15 2017KYOTO, Japan — The global push among carmakers to make ever lighter vehicles is leading some auto suppliers in Japan to turn to what seems like an unlikely steel substitute — wood pulp. Japanese researchers and auto component makers say a material made from wood pulp weighs just one-fifth of steel and can be five times stronger. The material - cellulose nanofibers — could become a viable alternative to steel in the decades ahead, they say, although it faces competition from carbon-based materials, and remains a long way from being commercially viable.> Related: Jay Leno drives the Renew cannabis car — hemp you can't dent Reducing the weight of a vehicle will be critical as manufacturers move to bring electric cars into the mainstream. Batteries are an expensive but vital component, so a reduction in car weight will mean fewer batteries will be needed to power the vehicle, saving on costs. "Lightweighting is a constant issue for us," said Masanori Matsushiro, a project manager overseeing body design at Toyota. "But we also have to resolve the issue of high manufacturing costs before we see an increased use of new, lighter-weight materials in mass-volume cars."A NEW PROCESS Researchers at Kyoto University and major parts suppliers such as Denso Corp, Toyota's biggest supplier, and DaikyoNishikawa Corp, are working with plastics incorporated with cellulose nanofibers — made by breaking down wood pulp fibers into several hundredths of a micron (one thousandth of a millimeter). Cellulose nanofibers have been used in a variety of products ranging from ink to transparent displays, but their potential use in cars has been enabled by the "Kyoto Process," under which chemically treated wood fibers are kneaded into plastics while simultaneously being broken down into nanofibers, slashing the cost of production to roughly one-fifth that of other processes. "This is the lowest-cost, highest-performance application for cellulose nanofibers, and that's why we're focusing on its use in auto and aircraft parts," Kyoto University Professor Hiroaki Yano, who is leading the research, told Reuters in an interview. The university, along with auto parts suppliers, are currently developing a prototype car using cellulose nanofiber-based parts to be completed in 2020.

Watch this video diary of a 900-hp Toyota Supra build

Sat, 08 Jun 2013If you've ever looked at a car with nearly 1,000 horsepower and wondered why anyone needs that amount of thrust, you may want to take a look at the video below. In it, one gentleman details his descent into Toyota Supra madness, starting with a pristine factory example and stumbling down the rabbit hole of modification. What makes this particular clip interesting is just how honest the owner is as he explains the evolution of his car. He doesn't just prattle off a list of parts like he's reading the menu at an IHOP.

Instead, he painstakingly pulls us through the car's growth, detailing each iteration and what pushed him to the next stage of the build every time. From this point of view, it looks less like someone walked into a shop and lit a massive stack of $100 bills on fire and more like a quasi-logical progression of events. Or at least it does to me. You can check out the build in the video below, complete with plenty of Fast and the Furious references and racing. Win, win, win.

Unifor may establish local union for Toyota's Canadian plants

Thu, 17 Jul 2014Union tactics apparently translate across borders, as Canada's Unifor may take inspiration from the United Auto Workers' recent move at the Volkswagen factory in Chattanooga, TN, and establish a local for the Toyota factories in Cambridge and Woodstock.

Unifor last attempted to organize the workers at the two factories, which are responsible for production of the Toyota Corolla (above), RAV4 and Lexus RX back in April, but that vote was eventually delayed. According to that report, 3,000 of the two plants' 7,500 employees signed union cards, but that apparently wasn't enough for Unifor to force a vote.

Because of this, the union is looking at the local approach, like what the UAW is attempting with VW.