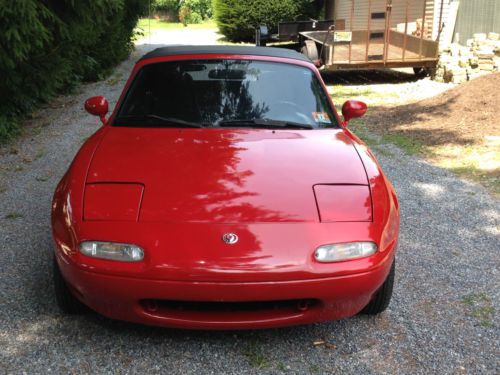

1993 Mazda Miata, Base Model, Runs And Looks Good on 2040-cars

Trenton, New Jersey, United States

|

Relocating must sell my 93 Miata. I've owned it for 6 years and had very few problems with it. Starts every time and runs smoothly with plenty of power. Good convertible top, some normal wear and fading of cloth seats. Power breaks and good tires. Some minor scratches and dings on exterior paint. Good sound system. Driver airbag is not functional.

|

Mazda MX-5 Miata for Sale

Auto Services in New Jersey

Woodbridge Transmissions ★★★★★

Werbany Tire And Auto Repair ★★★★★

Vonkattengell Transmission Service ★★★★★

True Racks Ltd ★★★★★

Top Dude Tint ★★★★★

TM & T Tire ★★★★★

Auto blog

Tech of the Year special, plus we drive the hydrogen Mirai and more | Autoblog Podcast #809

Fri, Dec 1 2023In this episode of the Autoblog Podcast, Editor-in-Chief Greg Migliore is joined by Senior Editor James Riswick and Road Test Editor Zac Palmer. They kick the discussion off by talking about what they've been driving as of late, including the Toyota Mirai, Dodge Hornet, Alfa Romeo Tonale and a trio of subcompact SUVs. After that, they dive into a discussion about the 2023 Autoblog Technology of the Year award winner, which is Mercedes-Benz's Dolby Atmos Spatial Audio. Once they wrap up that segment, we get to hear the crew's latest Cybertruck takes from before the big reveal. Finally, the show wraps up with a fun Spend My Money segment. Send us your questions for the Mailbag and Spend My Money at: Podcast@Autoblog.com. Autoblog Podcast #809 Get The Podcast Apple Podcasts – Subscribe to the Autoblog Podcast in iTunes Spotify – Subscribe to the Autoblog Podcast on Spotify RSS – Add the Autoblog Podcast feed to your RSS aggregator MP3 – Download the MP3 directly Rundown What we're driving 2023 Toyota Mirai 2023 Dodge Hornet 2024 Alfa Romeo Tonale 2024 Chevy Trax 2024 Kia Seltos 2024 Mazda CX-30 Turbo Technology of the Year winner and breakdown News Cybertruck preview Spend My Money Feedback Email – Podcast@Autoblog.com Review the show on Apple Podcasts Autoblog is now live on your smart speakers and voice assistants with the audio Autoblog Daily Digest. Say “Hey Google, play the news from Autoblog” or "Alexa, open Autoblog" to get your favorite car website in audio form every day. A narrator will take you through the biggest stories or break down one of our comprehensive test drives. Related video: Green Podcasts Alfa Romeo Chevrolet Dodge Kia Mazda Mercedes-Benz Toyota Technology Infotainment Technology of the Year Crossover SUV Electric Luxury Performance Sedan Podcasts

2002 Mazda MX-5 Miata powered by a Jaguar-sourced V6 for sale

Tue, Aug 25 2020Cars & Bids, a relatively new site that specializes in auctioning modern enthusiast cars, is selling a 2002 Mazda MX-5 Miata. While that's hardly unusual, this example lost its four-cylinder engine and gained a Jaguar-sourced V6. Pulling a 3.0-liter six out of a 2000 S-Type and dropping it into an unsuspecting Miata is apparently easier than it sounds. England-based Rocketeer offers a kit that makes the swap reasonably straightforward, though the listing notes the factory air conditioning system is not compatible with the new engine. Cold air aside, the installation is done so neatly that it looks like Mazda envisioned the Miata with a bigger engine. Jag's V6 inevitably adds weight to a roadster praised globally for its nimble handling, but it also brings a whole lot of horsepower to the table. Left stock, a 2002 Miata is powered by a 1.8-liter four-cylinder that makes 142 horsepower and 125 pound-feet of torque. The example listed on Cars & Bids puts 220 horsepower and 221 pound-feet of torque under the driver's right foot, figures that easily offset the weight gain. And, somewhat surprisingly, the six spins the rear wheels through a stock five-speed manual transmission. Flyin' Miata sway bars and Koni shocks improve handling. Close the hood, and this Jagazda looks like a run-of-the-mill 18-year-old Miata. The seller made no modifications to the body, it's still painted in its original shade of silver, and he kept the stock 15-inch wheels. The dual exhaust tips hint at the V6, but they're subtle enough to surprise more than a few racers at the next autocross event. The auction is live now, and bidding stands at $4,250 as of writing with about three days left before the hammer drops. If you miss your chance to bag it, several shops sell kits that let skilled shade-tree mechanics shoehorn Mazda's K-Series V6 (which powered the MX-6 and the Ford Probe, among other cars) into an older Miata. Related Video: This content is hosted by a third party. To view it, please update your privacy preferences. Manage Settings. Â Â Featured Gallery 2002 Mazda MX-5 Miata with Jaguar V6 View 14 Photos Aftermarket Jaguar Mazda Convertible

Mazda's first-quarter profit slumps on weak sales in U.S. and China

Thu, Aug 1 2019TOKYO — Mazda reported a 79% drop in quarterly operating profit, falling significantly short of estimates, as it continues to struggle with declining U.S. and Chinese sales, while a strengthening yen also cut into its bottom line. Operating profit at JapanÂ’s No.5 automaker was 7.0 billion yen ($64 million) in the first quarter ended June, versus around 33 billion yen a year ago and less than half of an average forecast for 18.5 billion yen from analysts polled by Refinitiv. Mazda, however, reiterated its forecast for a 33% rise in operating profit to 110 billion yen in the year ending March. ThursdayÂ’s profit announcement marks MazdaÂ’s poorest first-quarter operating performance since the June 2012 quarter. The automaker has been struggling with falling demand for its cars over the past year or so, while it is also recovering from flood-related damage to its factories in Japan that led to a quarterly loss in the July quarter of 2018. The Nikkei business daily on Wednesday had reported that operating profit at the company would fall around 70% for the quarter due to lower sales in the United States. Mazda posted global sales of 353,000 units for the quarter, down 12% from a year ago. Its sales in the United States, its biggest market, fell 15% to 68,000 units, while in China, Mazda sold 54,000 vehicles, down 21% on the year. A trade war between the top two economies and slowing growth in China, the worldÂ’s biggest auto market, have prompted a broad-based sales downturn in the global auto sector. Automakers are grappling with easing demand for cars just as they must invest heavily in new technologies including electric cars, autonomous driving technologies and ride-sharing services to survive a major industry shift away from car ownership. Many of MazdaÂ’s rivals at home and abroad have been reporting disappointing quarterly results, with Nissan and Ford also announcing job cuts and possible plant closures earlier this month. The United States is a key source of revenue for Mazda, but it imports all its vehicles sold there, exposing it to a threatened hike in U.S. tariffs on imported cars from Japan. To limit its vulnerability to possible tariffs and currency fluctuations, Mazda is investing in a new plant in the U.S. state of Alabama, a joint project with Toyota.

Mazda miata 2000

Mazda miata 2000 2001 mazda miata ls convertible 2-door 1.8l

2001 mazda miata ls convertible 2-door 1.8l 2001 mazda miata ls, 6 speed

2001 mazda miata ls, 6 speed 1992 mazda monster miata with ford 5.0 v8

1992 mazda monster miata with ford 5.0 v8 We finance! 2013 sport used certified 2l i4 16v manual rwd convertible premium

We finance! 2013 sport used certified 2l i4 16v manual rwd convertible premium Exceptional 2001 mazda miata

Exceptional 2001 mazda miata