$0.99 3.8l 4 All-season Tires Abs A/c 1 Owner Clean Carfax Smoke Free No Reserve on 2040-cars

Arlington, Virginia, United States

For Sale By:Dealer

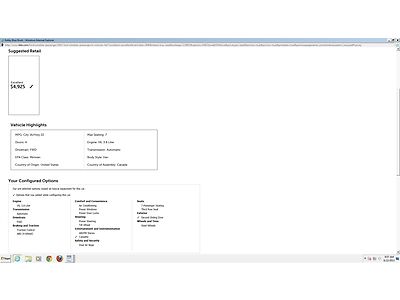

Transmission:Automatic

Body Type:Minivan, Van

Vehicle Title:Clear

Options: Cassette Player

Make: Ford

Power Options: Air Conditioning, Cruise Control, Power Locks, Power Windows, Power Seats

Model: Windstar

Mileage: 113,805

Sub Model: 3dr Windstar

Warranty: Vehicle does NOT have an existing warranty

Exterior Color: Blue

Vehicle Inspection: Inspected (include details in your description)

Trim: LX

Safety Features: Anti-Lock Brakes, Driver Airbag, Passenger Airbag, Side Airbags

Ford Windstar for Sale

2002 ford windstar sel mini passenger van 4-door 3.8l....no reserve

2002 ford windstar sel mini passenger van 4-door 3.8l....no reserve 2001 ford windstar lx - third seat - runs and drives great - very low reserve

2001 ford windstar lx - third seat - runs and drives great - very low reserve 75+pics clean autocheck certified one owner ~fully detailed~serviced

75+pics clean autocheck certified one owner ~fully detailed~serviced 2000 ford windstar se mini passenger van 4-door 3.8l

2000 ford windstar se mini passenger van 4-door 3.8l 2001 ford windstar se sport mini passenger van 4-door 3.8l~silver~see info(US $2,500.00)

2001 ford windstar se sport mini passenger van 4-door 3.8l~silver~see info(US $2,500.00) Ford windstar se sport 7 passenger minivan excellent condition(US $4,750.00)

Ford windstar se sport 7 passenger minivan excellent condition(US $4,750.00)

Auto Services in Virginia

Weaver`s Automotive ★★★★★

Wayne`s Auto Repair & Towing Service ★★★★★

Volvo Specialists Inc ★★★★★

Thomas Wheel Alignment & Tire Service ★★★★★

The Body Works of VA INC ★★★★★

The Body Works of VA INC ★★★★★

Auto blog

How Chevy Silverado, GMC Sierra will take on the Ford F-150 profit machine

Fri, Aug 10 2018FORT WAYNE, Ind. — When General Motors engineers were developing the 2019 Chevrolet Silverado and GMC Sierra pickup trucks, some of them joined public tours of Ford's Dearborn, Mich., factory to watch aluminum-bodied F-Series trucks go down the assembly line. The redesign of the Ford F-Series trucks, launched in 2014, set a new standard for fuel economy and lightweight vehicle construction. But armed with stopwatches and trained eyes, the GM engineers believed they saw problems. "They had a real hard time getting those doors to fit," Tim Herrick, the executive chief engineer for GM truck programs, told Reuters. His team did more intelligence gathering. They bought and tore apart Ford F-Series doors sold as repair parts. Their conclusion: GM could cut weight in its trucks for a lower cost using doors made of a combination of aluminum and high-strength steel that could be thinner than standard steel, shaving off kilograms in the process. These pounds-and-pennies decisions will have major implications in the highest-stakes game going in Detroit: dominance in the world's most profitable vehicle market, the gasoline-fueled large pickup segment. What's more, GM is banking on strong sales of overhauled 2019 Silverados and GMC Sierras to fund its push into automated and electric vehicles — a business many investors see as the auto industry's long-term future. The risks are high given the hits automakers have taken from U.S. President Donald Trump's trade policies. Rising aluminum prices spurred by Trump's tariffs are driving up costs on the Ford's F-Series, while rising steel and aluminum prices likewise drag on GM results. GM also has a significant risk should the United States, Mexico and Canada fail to agree on a new NAFTA trade deal, given GM trucks built at its Silao, Mexico, factory could face a 25 percent tariff if NAFTA collapses. Major profit per truck Interviews with GM executives and a tour at its factory here in northwest Indiana provide a detailed look inside GM's plan for the most important vehicles in its global lineup. These big pickups are everything Tesla's Model 3 or Chevy's Bolt electric car is not. The mostly steel body is bolted to the truck's steel frame, rather than the one-piece body and frame electric vehicles. The majority of trucks will have a V-8 gasoline engine powering the rear wheels — like the classic GM cars of the 1950s. Some Silverados will have new four-cylinder engines, but there is no electric or hybrid offering as of now.

This is what a 3D-printed liquid metal Ford Torino looks like

Sat, 12 Oct 2013Artist Ioan Florea has encapsulated a 1971 Ford Torino with 3-D-printed liquid metal transferred onto the car using technology that he developed, and the result is a stunningly shiny, seamless design.

"The surface has the highest coefficient of reflectivity never achieved before," Florea told us in an e-mail, using "nano-materials and nano-pigments that create an internal three-dimensional structure and dictate the polymer how to behave." Sure... We'll leave it to him to make any more 3-D-printed liquid metal-transferred art pieces.

Florea grew up in Romania, and the motivation behind picking the old Ford as his canvas came from his childhood memories of what an American car is - "big and wide and fascinating," he says - and the European name of the car itself, which it shares with an Italian city.

Latest Forza Motorsport 5 car pack leaves us scratching our head (in a good way) [w/video]

Wed, Jul 2 2014As we scrolled down the roster of the latest car pack for Forza Motorsport 5, the Hot Wheels Car Pack, our expression became bemused over the strange mix of vehicles that we now have at our disposal. This is quite unlike any of the other sets of DLC Turn 10 Studios has offered. Sure, there are the typical headliner cars – the Lamborghini Veneno and 2015 Audi S3 – that will appeal to the mainstream racing fan or auto enthusiast. But this latest car pack is so jammed full of nuggets of automotive weirdness that it's hard not to get excited. The Hot Wheels pack has no shortage of racers, with a particular focus on historical offerings. A 1939 Auto Union Type D covers the pre-war era of Formula One, while a 1967 Lotus 49 and a 1952 Ferrari 375 represent post-war racing. For a modern twist, a Mazda USF2000 car slots in below the Indy Lights car from the Nurburgring booster pack. From here, things get vintage and weird. There are a pair of delightfully offbeat coupes, in the form of a 1974 Toyota Celica GT and a 1973 Ford XB Falcon GT (here's hoping we get a vintage Holden Monaro in the future). Those two are joined by a 1956 Ford F-100, which your author already plans on converting into a dragster with vinyl flames down the side (because that's what all vintage pickups should be). The new ride we're most excited about, though, is the 1983 GMC Vandura G-1500. Yes, that's the van from The A-Team, and we're sure it will prove to be an excellent canvas for the artists of FM5 to cover with airbrushed, fire-breathing unicorns and mystical, gray-haired wizards (or just poorly painted letters that read "Free Candy"). This latest car pack is the final monthly car pack for FM5, although Turn 10 is quick to point out that while the monthly updates are over, there will still be new batches of cars made available to gamers. As for the Hot Wheels pack, it's available now on Xbox Live for $9.99. Scroll down for the press release from Turn 10 Studios, as well as a video of the newest additions to Forza Motorsport 5's vehicle roster. Forza Motorsport 5 Hot Wheels Car Pack Now Available Turn 10 Studios is bringing the Hot Wheels® Car Pack to "Forza Motorsport 5," available for download today. The pack features a collection of vehicles built from the ground up for the new generation that car fans can collect and customize while putting their virtual driving skills to the test.