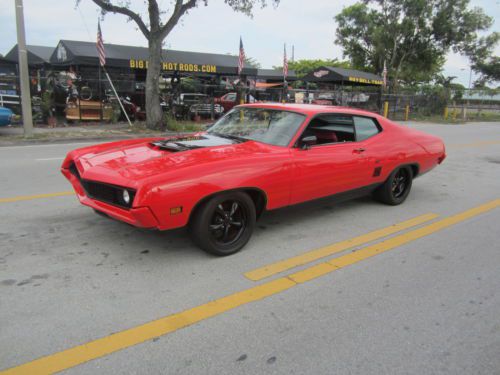

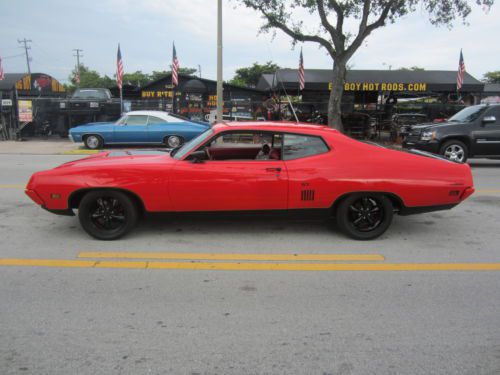

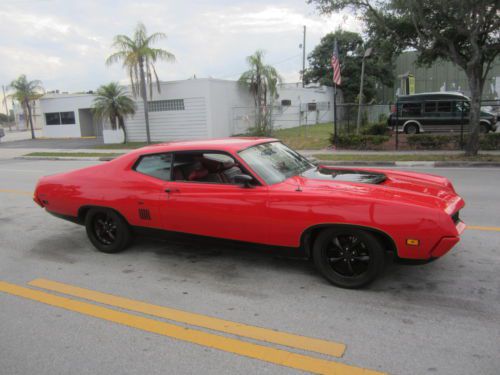

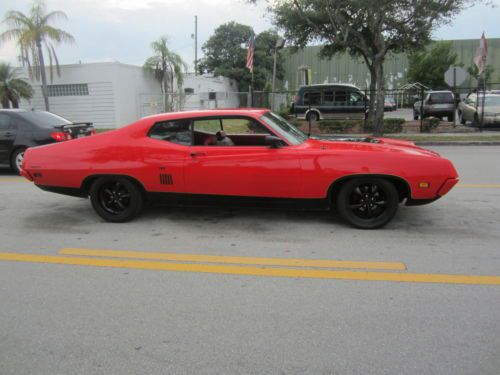

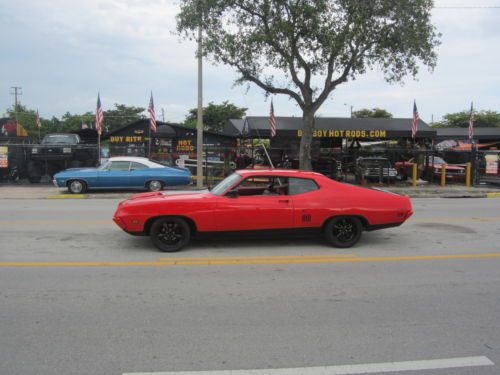

1970 Ford Torino Gt Big Block Muscle Car Rust Free Florida Car Make Offer on 2040-cars

Fort Lauderdale, Florida, United States

Ford Torino for Sale

1976 gran torino station wagon - 351 cleveland - fmx borg-warner transmission

1976 gran torino station wagon - 351 cleveland - fmx borg-warner transmission Folk's you just found the right one 1970 ford torino fastback 351 factory a/c .

Folk's you just found the right one 1970 ford torino fastback 351 factory a/c . 302 with manual trans - marti report - 2 owners- barn find solid oregon survivor

302 with manual trans - marti report - 2 owners- barn find solid oregon survivor 1969 ford torino gt 428 cobra jet - fast loud fun

1969 ford torino gt 428 cobra jet - fast loud fun 1971 ford torino 500 barn find 52k miles a/c auto 302 v8 2 dr muscle car

1971 ford torino 500 barn find 52k miles a/c auto 302 v8 2 dr muscle car Fully restored 351 4 br 1968 ford torino gt convertible stunning through out wow

Fully restored 351 4 br 1968 ford torino gt convertible stunning through out wow

Auto Services in Florida

Zip Auto Glass Repair ★★★★★

Willie`s Paint & Body Shop ★★★★★

Williamson Cadillac Buick GMC ★★★★★

We Buy Cars ★★★★★

Wayne Akers Truck Rentals ★★★★★

Valvoline Instant Oil Change ★★★★★

Auto blog

2017 will be the year the connected car becomes a reality

Fri, Jan 13 20172016 was full of talk of autonomy, but little action beyond crazy, futuristic concept cars and announcement after announcement from automakers. If this year's CES is any indication, 2017 is going to focused on connectivity. More than that, CES showed that traditional barriers between automakers are breaking down in favor of universal and open source technology standards that will benefit both consumers and developers. CES, traditionally a showcase for the latest and greatest technology and gadgets like flat-screen refrigerators or televisions that broadcast in the fifth dimension, has become so intwined with the auto industry that we at Autoblog cover it like any other auto show. At every CES event I attended and nearly every booth I went to, there was some talk, display, or demonstration of how cars will connect to your phone and your home, and eventually each other. It seems we're heading toward the tech singularity where all devices work under one cohesive ecosystem – the Internet of Things, if you like. The difference between autonomy and connectivity is how real the latter feels because so much of the connected tech on display at CES is either here already or will be here by the end of the year. There were dozens of demos, both big and small, that allowed us to test and explore what's on the horizon. Bridging the gap between home and car, Ford is integrating the Amazon Alexa personal assistant straight into its vehicles. That means you'll be able to talk to Alexa in your car just like you would through an Echo or Dot at home. It also means you can shop on Amazon by voice while you're driving (since that wasn't convenient enough already). Samsung is developing smartwatch applications for Ford, BMW, and others. Toyota is adopting Ford's SmartDeviceLink smartphone connectivity system for its vehicles. That means developers can have one app that works across multiple infotainment systems. The Linux Foundation is developing an open-source operating system that will be free to use, making it easier for developers to connect smartphones and apps across multiple manufacturers' systems. Automotive Grade Linux, or AGL, is available for download right now. Major automakers like Toyota and Daimler (who usually are set on competing with one another) are partnering to further the development of the project. Bosch, Hyundai, and Chrysler showed connected car concepts at CES that preview the future of automobiles.

Ford recalls 462,000 SUVs over faulty rear camera

Fri, Jan 27 2023Ford has had some issues with its backup cameras in recent years, and the troubles are continuing with yet another recall announced today. In this recall, certain Ford and Lincoln vehicles equipped with the 360-degree parking camera could lose the rear-view camera feed. The newest recall affects some 462,000 vehicles worldwide, Reuters reports, including 382,759 in the U.S. under NHTSA recall 23V-022. The recall applies to the 2020-2023 Ford Explorer and Lincoln Aviator, as well as the 2020-2022 Lincoln Corsair. The remedy involves dealers updating the vehicles’ image processing module software free of charge. This latest issue expands a previous recall, and applies to vehicles that have already been serviced under recall 21V-735. Owners will be notified by mail around February 20, and owners can also contact Ford customer service at 1-866-436-7332. Ford told NHTSA that it first became aware in October 2021 of a small number of complaints of a blue screen from the rear camera feed on vehicles that had already been repaired. Ford worked with suppliers to track down the potential issue, and said warranty claims remained low until December 2022, when it started to see more claims for blue screens in vehicles produced after the last remedy, at which point Ford ordered a stop-ship on those vehicle lines. Ford said itÂ’s aware of 17 minor accident reports related to the issue, but no injuries. In addition to this recall, Ford has had other camera issues in the past few years that resulted in recalls. NHTSA recall 22V-151 applied to 2021-2022 Edge SUVs experiencing “a distorted, black and white, or discolored screen” when reversing. 2021-2022 Ford Broncos had an issue where the rear-view camera would remain on even after the vehicle was put back into a forward gear. Last year, Ford recalled 330,000 Mustangs for faulty cameras, as well as 277,000 Super Duty trucks over foggy rear-view cameras. In 2021, NHTSA opened an investigation into whether Ford was slow to recall more than 620,000 vehicles for faulty cameras. Recalls Ford Lincoln Safety Crossover SUV

Ford spotted testing new Focus RS at the Nurburgring

Thu, 26 Jun 2014Ford is expected to be launching a revised version of the Focus ST soon, but the latest snapshots from our spy photographers at the Nürburgring suggest that the Blue Oval is already working on an even more potent example: the new Focus RS.

Though the partially disguised test mule is wearing an ST badge (along with a Dewey sticker that makes us wonder what adventures Huey and Louie are up to and what manner of duck-tail rear spoiler they may be wearing), there are several tell-tale signs that something else is afoot here. There's a larger front air dam, bigger brake calipers, dual exhaust tips (instead of the central exhaust on the ST) and a reshaped wing protruding from the trailing edge of the roof.

That may all be well and fine, but what's under the hood? We don't know yet for sure, but word has it that Ford is preparing to port over the 2.3-liter turbo four offered in the new Mustang, where it packs 305 horsepower and almost as much torque - potentially retuned to produce even more for the top-of-the-line Focus, which could channel it all to the front wheels like the last model or pack an all-wheel drive system. The Global C platform on which the Focus is based does, after all, also underpin AWD models like the Ford Escape and Lincoln MKC.