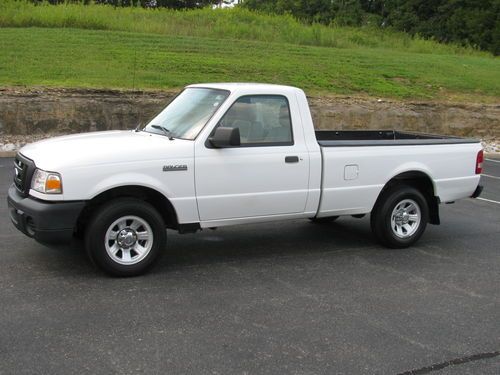

2000 Ford Ranger Truck. Great Condition,automatic,new Tires, Great Paint on 2040-cars

Hickory, North Carolina, United States

Body Type:Pickup Truck

Vehicle Title:Clear

Engine:3000 SIZE

For Sale By:Private Seller

Make: Ford

Model: Ranger

Cab Type (For Trucks Only): Regular Cab

Trim: 2 DOORS

Options: Cassette Player

Drive Type: AWD

Safety Features: Driver Airbag, Passenger Airbag

Mileage: 252,082

Power Options: Air Conditioning

Exterior Color: Gray

Interior Color: Gray

Disability Equipped: No

Number of Cylinders: 6

Warranty: Vehicle does NOT have an existing warranty

2000 Ford Ranger tuck is great for light hauling, drive on snow, and rural areas. The truck can fit up to 4 people. Automatic. Truck has a few dent on the front but it drive very nice. Please call Glen Jonas at 828-308-8663 if you like to get more details or if you have any questions. Thank you!

Ford Ranger for Sale

2010 ford ranger xl standard cab pickup 2-door 4.0l * runs and looks great!!(US $9,995.00)

2010 ford ranger xl standard cab pickup 2-door 4.0l * runs and looks great!!(US $9,995.00) 2010 ford ranger xl standard cab pickup 2-door 2.3l * sharp!! gas saver!!(US $8,995.00)

2010 ford ranger xl standard cab pickup 2-door 2.3l * sharp!! gas saver!!(US $8,995.00) 2000 ford ranger xlt

2000 ford ranger xlt 1998 ford ranger xlt standard cab pickup 2-door 2.5l

1998 ford ranger xlt standard cab pickup 2-door 2.5l 2011 ford ranger xlt 4dr supercab 4 x 4 5-speed automatic

2011 ford ranger xlt 4dr supercab 4 x 4 5-speed automatic 2000 ford ranger pickup 2-door 2.5l(US $2,900.00)

2000 ford ranger pickup 2-door 2.5l(US $2,900.00)

Auto Services in North Carolina

Westside Motors ★★★★★

VIP Car Service ★★★★★

Vann York Toyota Scion ★★★★★

Skip`s Volkswagen Service ★★★★★

Sharky`s Auto Glass ★★★★★

Randy`s Automotive Repair ★★★★★

Auto blog

Automakers want to stop the EPA's fuel economy rules change, and why that's a shortsighted move

Tue, Dec 6 2016With a Trump Administration looming, the EPA moved quickly after the election to propose finalizing future fuel economy rules last week. The auto industry doesn't like that (surprise), and has started making moves to stop the EPA. Ford CEO Mark Fields said he wanted to lobby Trump to lower the standards, and now the Auto Alliance, a manufacturer group, is saying it will join the fight against cleaner cars. The Alliance represents 12 automakers: BMW, Fiat Chrysler, Ford, GM, Jaguar Land Rover, Mazda, Mercedes-Benz, Mitsubishi, Porsche, Toyota, VW, and Volvo. Gloria Bergquist, a spokesperson for the Alliance, told Automotive News that the "EPA's sudden and controversial move to propose auto regulations eight months early - even after Congress warned agencies about taking such steps while political appointees were packing their bags - calls out for congressional action to pause this rulemaking until a thoughtful policy review can occur." The EPA was going to consider public comments through April 2017, but then said it would move the deadline to the end of December. That means that it can finalize the rules before President Obama leaves office. The director of public affairs for the Consumer Federation of America, Jack Gillis, said on a conference call with reporters last week when the EPA originally announced its decision that it is unlikely that President Trump will be able to roll back these changes. Gillis also said on the same call that any attempt by the automakers to prevent these changes would be history repeating itself. "These are the same companies that fought airbags, and now promoting the fact that every car has multiple airbags," he said. "These are the same companies that fought the crash-test program, and now are promoting the crash-test ratings published by the government. So, it's clear that they're misperceiving the needs of the American consumer." There are more reasons the Allliance's pushback is flawed. Carol Lee Rawn, the transportation program director for Ceres, said on that call that the automotive industry is a global one, and many automakers are moving to global platforms to help them meet strict fuel economy rules around the world.

Weekly Recap: Toyota, Mazda team up to 'make cars better'

Sat, May 16 2015Toyota and Mazda are teaming for a noble purpose: to "make cars better." That's how the two Japanese automakers termed their partnership, which was announced this week. So what does this actually mean? The companies said they will set up a joint committee to look for areas of cooperation and named safety and the environment as issues they plan to tackle. From a product perspective, it's believed that Toyota is interested in Mazda's Skyactive engine portfolio. In turn, Mazda has its eye on Toyota's fuel-cell and plug-in hybrid technology. While more specifics were not confirmed, the companies said the "agreement will go beyond the traditional framework of cooperation," and it has the potential to be a long-range partnership. "The main purpose of this initiative is to enhance the appeal of our cars," Toyota president Akio Toyoda said at the announcement. Previously, Mazda has licensed Toyota's hybrid tech and assembled compact cars for Toyota in Mexico. Akio Toyoda said these projects "triggered" the automakers to explore further collaboration. Dave Sullivan, product analysis manager for AutoPacific, said the tie-up echoes Daimler's wide-ranging work with the Renault-Nissan alliance. "This could be a well-groomed match due to each having very unique skill sets," he said. OTHER NEWS & NOTES Volvo selects South Carolina for US factory Volvo confirmed this week that it will build its first US factory in South Carolina, with construction set to begin this fall. The company first revealed plans in March, though it didn't announce a site. The plant will have initial annual production of 100,000 units, though the vehicle or vehicles to be assembled were not specified. The factory, located near Charleston, will open in 2018 and ultimately employ 4,000 people. The facility will help Volvo continue its growth strategy, which includes strengthening its presence in the US market, where it wants to sell more than 100,000 cars per year. "Building a plant in the US is a reflection of Volvo Cars' commitment to the US and the key role the US plays in our growth objectives," Lex Kerssemakers, senior vice president, Americas, said in a statement. Ford GT spied on the road The 2017 Ford GT was spotted testing around the Blue Oval's headquarters in Dearborn, MI, this week. The raw body panels were exposed, and they lacked paint or camouflage. It's the first time the GT has been captured on the street after a spring of auto show reveals.

Ford CEO Jim Hackett reviewing the future of technology, Lincoln, overseas markets

Mon, Jul 31 2017By Paul Lienert and Joseph White Ford Chief Executive Jim Hackett is reviewing the automaker's operations in India and other markets, as well as Ford's future product programs including plans to build a self-driving commercial vehicle in 2021. Hackett, who took over as CEO in May, has told investors he is working on a 100-day review of Ford's operations but has so far provided few details of the process, except to indicate that it is looking at the automakers' luxury vehicle strategy, the future of its small vehicles and investments in emerging markets. Ford Chief Financial Officer Bob Shanks told Reuters in an interview that the review covers a range of issues, including Ford's strategy for India. "We have a lot of work to do (as) we address issues of how to fix India," Shanks said. "Everything is on the table." General Motors in May said it would stop selling cars in India but continue to produce vehicles there for export. Shanks said no decisions have been made and noted that Ford has a larger business in India than GM did. "We are very cognizant that will be the third-largest market in the world," he said. "Some big decisions will be made," Shanks said, but he cautioned Ford may not disclose all those decisions at the end of the 100-day review. Hackett is addressing challenges that have contributed to a nearly 8 percent decline in Ford's share price this year. The review of the Lincoln luxury brand includes whether current plans will meet former CEO Mark Fields' ambitious targets for growth and revenue, people familiar with the process said. Ford has set a target of putting a self-driving shuttle into commercial ride-sharing fleets by 2021. Hackett is reviewing the investment and timing for that project, the sources said. Hackett also assessing whether to reduce and consolidate production of models such as the Fiesta subcompact and two midsized sedans that are built in multiple locations around the world, but are experiencing slowing demand. One proposal would shift production of the next-generation Mondeo midsized sedan from Europe to Mexico, where it would share an assembly line with its sibling, the Ford Fusion, avoiding the cost of retooling two plants. Shortly after he took charge, Hackett approved a proposal to shift production of the next-generation Focus for North America from Mexico to China, saving the company an estimated $500 million by consolidating two factories into one.