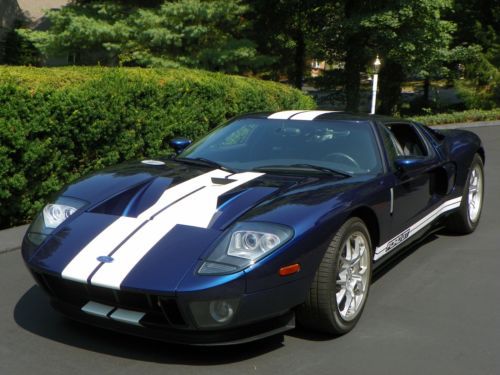

Heritage Edition 6 Miles Open Mso Only 343 Made on 2040-cars

Lynnwood, Washington, United States

Engine:8

Transmission:Manual

Body Type:Coupe

Vehicle Title:Clear

Fuel Type:Gas

Used

Year: 2006

Make: Ford

Disability Equipped: No

Model: Ford GT

Doors: 2

Drivetrain: Rear Wheel Drive

Mileage: 6

Trim: Base Coupe 2-Door

Exterior Color: Blue

Drive Type: RWD

Interior Color: Black

Number of Cylinders: 8

Ford Ford GT for Sale

2005 ford ford gt collector quality call chris (816)365-6010(US $269,988.00)

2005 ford ford gt collector quality call chris (816)365-6010(US $269,988.00) 2k miles black rare stripe delete bbs wheels mcintosh stereo grey calipers(US $295,980.00)

2k miles black rare stripe delete bbs wheels mcintosh stereo grey calipers(US $295,980.00) 2005 3 option, 1 owner, rare quick silver!!! andy house 1-936-414-2295(US $255,000.00)

2005 3 option, 1 owner, rare quick silver!!! andy house 1-936-414-2295(US $255,000.00) 645 miles, showroom new, mcintosh sound, wheels, gt40, supercharged, 6spd, 550hp(US $309,995.00)

645 miles, showroom new, mcintosh sound, wheels, gt40, supercharged, 6spd, 550hp(US $309,995.00) 2006 ford gt rare midnight blue all 4 options(US $249,000.00)

2006 ford gt rare midnight blue all 4 options(US $249,000.00) 2005 ford gt--10 miles as new all 4 options(US $329,000.00)

2005 ford gt--10 miles as new all 4 options(US $329,000.00)

Auto Services in Washington

Wayne`s Service Center ★★★★★

Wagley Creek Automotive ★★★★★

Tri-Cities Battery & Tire Pros ★★★★★

Trailer Town ★★★★★

Systems Unlimited ★★★★★

Steve`s Moss Bay Repair & Towing ★★★★★

Auto blog

UPDATE: GM, Ford, FCA, Honda shutting down all North America plants

Wed, Mar 18 2020Following an earlier report that General Motors, Ford and FCA would take action to curtail the potential spread of the Coronavirus, news comes today that the three American automakers will instead close all North American plants for an unknown period of time. Ford said in a statement that it "is temporarily suspending production at its manufacturing sites in North America to March 30 to thoroughly clean its facilities to protect its workforce and boost containment efforts for the COVID-19 Coronavirus." General Motors followed with a statement confirming that its suspension "will last until at least March 30," and adding that the situation will be reevaluated from week to week after that. FCA has not yet issued an official statement. Rory Gamble, president of the United Auto Workers union, praised the news. "This will give us time to review best practices and to prevent the spread of this disease," Gamble said in a statement. According to the Associated Press, around 150,000 workers are "likely to receive supplemental pay in addition to unemployment benefits." The United Auto Workers had asked the automakers to reconsider their position on Wednesday, a day after the parties agreed to slow production at U.S. plants and limit the number of workers on the job at one time to prevent the spread of the virus, a source who asked not to be identified told Reuters. The UAW’s new request for the closure of the Detroit Three automakersÂ’ U.S. plants came after Honda said on Wednesday it was temporarily shutting its North American plants for six days because of the anticipated decline in consumer demand. Plants/Manufacturing UAW/Unions Chrysler Fiat Ford GM coronavirus

Ford rolls out Vignale Mondeo for upscale European buyers

Tue, Apr 21 2015North American buyers looking for a luxury automobile from Dearborn know to turn to Lincoln, but overseas, the Ford brand itself appeals to upscale customers with its own products. The Blue Oval automaker unveiled a premium take on the Taurus for the Chinese market at the Shanghai Motor Show this weekend, and in Europe it's rolling out the Vignale sub-brand with the model you see here. Previewed in concept form a year and a half ago at the Frankfurt Motor Show, the Vignale line revives the name of a storied Italian coachbuilder that Ford acquired (together with Ghia) back in 1973. Now ready for production, the first Vignale model upgrades on the Mondeo (which we know as the Fusion) with a number of high-end features. The cabin space is altogether more luxurious, featuring high-end, laser-cut leather trim with hexagonal quilting and "tuxedo" stitching. The multi-contour front seats have a massage function, and occupants are better isolated from the road via upgraded sound insulation and active noise cancellation. The Ford Vignale Mondeo benefits from all the latest safety-convenience and infotainment technologies, including an optional Sony digital audio system with twelve speakers. The exterior is made to look more upscale as well, with unique metallic paint finishes, special chrome trim, 18-inch alloys and the requisite special badging to set it apart from ordinary Mondeos. Buyers will be able to choose between sedan or wagon body styles, front- or all-wheel drive and from a number of engine options. There's a 2.0-liter EcoBoost four with 237 horsepower, a 2.0-liter turbodiesel available with 177 or 207 hp, and a gasoline-electric hybrid system with 184 hp. Each vehicle is hand-finished and individually inspected at the Vignale Centre at Ford's plant in Valencia, Spain, and will be offered through select dealerships outfitted with premium Vignale Lounges. Customers will also benefit from access to a dedicated "relationship manager," customer assistance operators on call 24 hours a day and a companion app, but of course none of these features come cheap: At around GBP30k in the UK, the price of a Vignale Mondeo comes close to that of an Audi A6 or Jaguar XF, and it'll be up to individual buyers to decide whether the spruced-up Fusion is worth the premium. Look for a Vignale version of the S-Max to follow.

Expert: 54.5 mpg CAFE standard can be reached without many plug-ins

Sat, Jan 18 2014Johnson Controls executive Brian Kesseler isn't likely to get any holiday presents this year from Nissan chief Carlos Ghosn or Tesla Motors head Elon Musk, but lots of other folks might be happy with what he has to say about automakers' efforts to reach stricter fleetwide fuel-economy standards. Speaking at the Automotive News World Congress, Kesseler said automakers wouldn't need to sell an extensive number of plug-in vehicles in order to meet the 54.5 mile per gallon Corporate Average Fuel Economy (CAFE) standard the US government set in 2012 for 2025 model-year vehicles. In fact, he said, components such as stop-start engine technology, turbochargers and direct injection may actually do the trick. Already, things like smaller engine sizes and lighter cars are already playing major roles in spurring fuel-efficiency gains. Of course, Johnson Controls sells batteries specially built for stop-start systems, so Kesseler does have a bit of skin in this game. The 54.5-mpg CAFE standard equates to about a 40-mpg "real world" fuel-efficiency level. To put that into perspective, the Environmental Protection Agency (EPA) said in a report late last year that model-year 2013 average fuel economy was an even 24 mpg. That was up from 23.6 mpg for the 2012 model year and 22.4 mpg for 2011. News Source: Automotive NewsImage Credit: AP Government/Legal Green Ford Fuel Efficiency mpg CAFE standards ecoboost johnson controls

2040Cars.com © 2012-2025. All Rights Reserved.

Designated trademarks and brands are the property of their respective owners.

Use of this Web site constitutes acceptance of the 2040Cars User Agreement and Privacy Policy.

0.06 s, 7974 u