2007 Ford Focus on 2040-cars

1010 Old US Hwy 1, Southern Pines, North Carolina, United States

Engine:2.0L I4 16V MPFI DOHC

VIN (Vehicle Identification Number): 1FAFP31N07W258078

Stock Num: F8139A

Make: Ford

Model: Focus

Year: 2007

Exterior Color: Cd Silver Metallic

Options: Drive Type: FWD

Number of Doors: 2 Doors

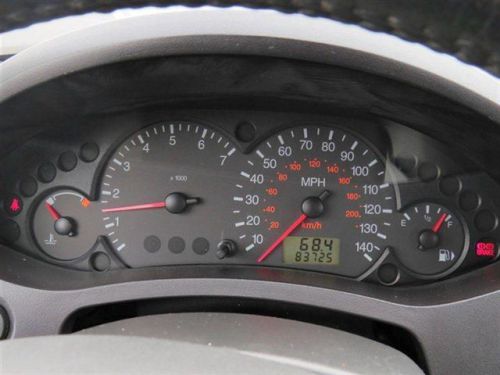

Mileage: 83612

This 2007 Ford Focus 3dr Coupe features a 2.0L I4 FI DOHC 4cyl Gasoline engine. The vehicle is CD Silver Metallic with a Other interior. It is offered As-Is, extended warranty is available. - Power Steering, AM-FM, Bucket Seats, Rear Bench Seat,Rear Bench Seat - Contact Internet Manager at 877-349-3642 or webleads.cflsp@crossroadscars.com for more information. -

Ford Focus for Sale

2014 ford focus titanium(US $24,599.00)

2014 ford focus titanium(US $24,599.00) 2004 ford focus lx

2004 ford focus lx 2007 ford focus se(US $8,750.00)

2007 ford focus se(US $8,750.00) 2012 ford focus se(US $17,860.00)

2012 ford focus se(US $17,860.00) 2014 ford focus se(US $19,890.00)

2014 ford focus se(US $19,890.00) 2012 ford focus titanium(US $20,640.00)

2012 ford focus titanium(US $20,640.00)

Auto Services in North Carolina

Walkertown Tire Service ★★★★★

Victory Tire & Auto Svc ★★★★★

Valvoline Instant Oil Change ★★★★★

USA Paint & Body ★★★★★

Truth Automotive-Transmission ★★★★★

Triangle Window Tinting ★★★★★

Auto blog

2015 Ford Mustang 50th Anniversary Edition says 'happy birthday' in New York

Wed, 16 Apr 2014Fifty years ago this week, Ford debuted the first-ever Mustang at the New York World's Fair. And to celebrate, the Blue Oval is offering up this special, 50th Anniversary Edition 2015 Mustang, which makes its debut at the New York Auto Show. It'll be a seriously limited affair, with only 1,964 examples of the special edition Mustang slated to be produced (the number chosen to coincide with the 'Stang's first year in production). But for those who raise their hands for the 50th Anniversary package, there's a pretty sweet package in store.

The 50th Anniversary Edition is based on the 2015 Mustang GT with the Performance Pack, and is only available in two colors: Kona Blue, or Wimbledon White (pictured). The car also comes fully loaded - the only option for buyers to choose is the transmission. Should you opt for the six-speed automatic, you'll get a limited-slip rear differential with a 3.55:1 final-drive ratio (the 50th Anniversary car is also the only way to get a slushbox-equipped 'Stang with the Performance Pack). Selecting the six-speed manual 'box will net you a Torsen differential with a 3.73:1 ratio. All 50th Anniversary cars will be powered by Ford's 5.0-liter, naturally aspirated V8, estimated to produce more than 420 horsepower and 390 pound-feet of torque in the 2015 Mustang.

Inside, there's a cashmere-stitched, leather-wrapped steering wheel, with a similar detail found on the instrument panel, shift boot, door inserts, seats, and center armrest. Two-tone leather/black upholstery is also part of the 50th Anniversary package, and of course, there's a special logo on the seats.

The 2021 F-150 elevates Ford's bed game

Fri, Jun 26 2020The new 2021 Ford F-150 is ushering in a new era of pickup capability, but there's more to it than the introduction of the PowerBoost hybrid. While that new powertrain is certainly the truck's headlining element, the supporting electrical architecture enables a level of utility that hasn't been offered in past consumer half-tons. The true party trick is Ford's new "Pro Power Onboard" feature, which is essentially a built-in generator that provides juice for the 2021 F-150's rather robust in-bed power station. This system is available even on gasoline-engine models, but its utility is maximized with the electrified powertrain. ICE models equipped with the option max out at 2.0 kilowatts, while the PowerBoost hybrid can be had with either a 2.4- or a whopping 7.2-kilowatt inverter. The idea here is that the F-150 can essentially stand in for a high-output portable generator. In a worksite example provided by Ford, a PowerBoost model with the 7.2-kW upgrade and a single tank of fuel could provide 32 hours of power for an 1,800-watt compound miter saw, a 1,000W circular saw, a 1,200W battery charger, a 1,200W hammer drill, and a 1,000W air compressor with hundreds of watts to spare for lighting and other accessories. But even without the Pro Power Onboard option, Ford's new bed setup enables more versatility than in previous models. The new Tailgate Work Surface option adds a flat work area with integrated rulers, recesses for pencils or small tools, and even a stand for a personal device. Ford is neither the first to offer an auxiliary power outlet in a half-ton pickup bed, nor was Ford the first to introduce a more feature-rich tailgate. GMC's MultiPro tailgate was a major innovation on that front, and while it is geared mostly toward improving the cargo utility of the bed, it can also be customized with 12-volt power and even an accessory speaker system. The Ram 1500 is also offered with both a multi-function tailgate and AC power in the bed, though the latter option is limited to models with the RamBox cargo package. As half-ton pickups approach levels of towing and hauling capability that begin to blur lines with heavy-duty offerings, it's clear that automakers are looking for ways to differentiate themselves without stepping on their own bigger trucks' toes. These new bed and tailgate innovations may yet be the tip of the iceberg when it comes to full-size pickup versatility. Related Video:

Ford readying Ranger-based Everest SUV?

Fri, 21 Feb 2014Way back in August, we showed you a Ford concept for the Australian market called the Everest. Now, we can show you that work on the new Ranger-based SUV is well under way.

At this stage, it's still quite clearly a mule (note the misalignment of the front and rear doors), wearing the Ranger's front end and the rump of Ford's overseas Territory crossover. The wheelbase is shorter than a Ranger, according to our spy photographers, which strikes us as somewhat odd for a more passenger-oriented vehicle. Disc brakes should be fitted at all four corners, while the new SUV, which will almost certainly wear the Everest name, should sport a new rear suspension.

In terms of looks, we're expecting the Everest Concept to inform the appearance of the production model. Naturally, there will also be some interior tweaks, particularly around the dashboard, which is covered in these photos.