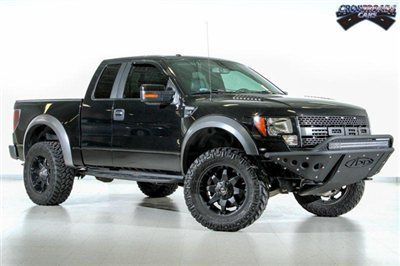

10 Svt Raptor Navigation Sunroof Airaid Rigid Industries 35" Nitto Fuel Add Part on 2040-cars

Cary, North Carolina, United States

Fuel Type:Gasoline

For Sale By:Dealer

Transmission:Automatic

Body Type:Pickup Truck

Make: Ford

Options: Leather

Model: F-150

Safety Features: Anti-Lock Brakes, Driver Side Airbag

Mileage: 46,250

Power Options: Air Conditioning, Power Door Locks

Sub Model: 4WD SuperCab 133" SVT Raptor

Exterior Color: Black

Interior Color: Black

Doors: 4

Number of Cylinders: 8

Cab Type: Estended Cab

Engine Description: 6.2L 2V EFI V8

Drivetrain: 4-Wheel Drive

Warranty: Vehicle does NOT have an existing warranty

Ford F-150 for Sale

2010 ford fi50 xlt 4x4 4 wheel drive extended cab automatic trans pickup

2010 ford fi50 xlt 4x4 4 wheel drive extended cab automatic trans pickup We finance!!! 2010 ford f-150 platinum 4x4 flex-fuel roof nav sync texas auto(US $34,998.00)

We finance!!! 2010 ford f-150 platinum 4x4 flex-fuel roof nav sync texas auto(US $34,998.00) 2006 ford f150 f-150 crew cab supercrew 4x4 4wd 5.4 triton body damage

2006 ford f150 f-150 crew cab supercrew 4x4 4wd 5.4 triton body damage 2001 ford f150 xlt 4x4

2001 ford f150 xlt 4x4 12 ford f-150 xlt 4x4 eco boost 35" toyo tires 6" lifted 18" helo alloy wheels

12 ford f-150 xlt 4x4 eco boost 35" toyo tires 6" lifted 18" helo alloy wheels 1995 ford f-150 eddie bauer lifted on 33's , clean ice cold a/c(US $7,500.00)

1995 ford f-150 eddie bauer lifted on 33's , clean ice cold a/c(US $7,500.00)

Auto Services in North Carolina

Wilburn Auto Body Shop-Mooresville ★★★★★

Westover Lawn Mower Service ★★★★★

Truck Alterations ★★★★★

Troy Auto Sales ★★★★★

Thee Car Lot ★★★★★

T&E Tires and Service ★★★★★

Auto blog

Buyers ditching expensive European sedans to buy expensive American trucks

Mon, Feb 19 2018The New York Times ended the automotive week with a story that adds numbers and context to a range of other stories, from the crossover craze to the increasing median price of a new car to ever more grandiose pickup trucks. The NYT piece reveals that the shift to larger vehicles isn't merely about the average U.S. buyer swapping the midsize sedan for a Ford Edge. Luxury buyers are migrating from plush sedans to plush SUVs and trucks that creep close to six-figure prices, and the Detroit Three are running Treasury presses because of it. From 2013 to 2017, the truck category — everything from pickups to minivans — climbed from 30 percent of the market to 41 percent. In January of this year, trucks claimed 66 percent of new vehicle sales. At the milk-and-honey end of profits, GMC alone accounted for 11.3 percent of all vehicle sales over $60,000, not just trucks. That puts the luxury truck maker behind Mercedes-Benz and Ford, The Blue Oval's feasting on Lariat, King Ranch and Raptor versions of the F-150, which make up more than half of that pickup's sales, putting it ahead of Chevrolet, Porsche and Lexus on the high-dollar sales list. The average transaction price of a GMC in Denali trim last year was $56,000; it's easy to see why, when one dealer told the NYT he just swapped a 2012 BMW 550i for a $71,000 GMC Sierra Denali. That truck starts at $52,900. The NYT started its story with a buyer who took home a Ford Raptor instead of an Audi A6, and optioned that $50,020 Ford Raptor close to $80,000. Over at Lincoln, the new $72,055 Navigator — the one so popular that Ford will increase production — crossed hands for an average sale price of $77,000 in January. And a Jeep dealer told the NYT that the two $93,000 Trackhawks he had on his lot "won't be here more than a few weeks." While trucks head up in sales volume and price, cars are headed so viciously in the opposite direction that "the Detroit Three and even some foreign manufacturers acknowledge they are now losing money on many of the cars they sell." So ... get ready for a lot more crossovers and trucks. Related Video: Find out what vehicle is right for you. Give our Car Finder tool a try.

249 reasons you want to go to Goodwood Revival

Sat, Sep 16 2023At its most basic, Goodwood Revival is a long weekend worth of car races featuring cars made before 1970. There are lots of those, though, including some pretty great ones all over the world. But nothing is like Goodwood Revival because it's so much more than "just" vintage car racing. First, you have to look the part. Attendees are strongly encouraged to dress in period clothing from the 1940s, 1950s and 1960s, with a strict dress code enforced should you want to enter the paddock. The goal is to create a more authentic atmosphere to match the cars and the meticulously restored and recreated paddocks, grandstands and other facilities of the reborn Goodwood circuit. Now, the dress code was relaxed this year since the Saturday was literally the hottest Sept. 9 on record in that part of England, and the organizers didn't want people dropping dead because they needed to wear an ascot. Some people definitely took the "relaxed" bit too far, but there was still plenty of atmosphere maintained. It really does make a big difference, as those "relaxed" individuals were often akin to seeing a Starbucks cup in a scene from "Game of Thrones." You can see what I came up with below along with former Autoblog editor Reese Counts and various other Goodwood attendees. Second, there's the parking lot. But I'll let this entire separate post detail that. Third, there's the enormous carnival-like area featuring vintage-looking rides and various boutiques. Both of those are on the outside portion of the track, and honestly, you could easily just spend your entire day in the parking lot and carnival/shopping area without even crossing over into the circuit area. There you'll find more shops, food and drink opportunities, plus obviously, race car paddocks and the track itself. Fourth, there are airplanes! I heard there are fewer than in the past, but they're there and they're cool. The Goodwood circuit started out life as the perimeter road around the World War II airfield RAF Westhampnett. Fifth, with all of the above, Goodwood Revival really is fun for the whole family. It isn't just a bunch of old guys sitting around in lawn chairs. There are plenty of women and adorably dressed children, including babies in vintage prams. It's also not an event that's exclusively for the uber rich, even if they are certainly in full force given who has the sort of money needed to go vintage racing.

Jeep Moab Concepts, Rumors, And More | Autoblog Podcast #470

Fri, Mar 11 2016Episode #470 of the Autoblog Podcast is here. This week, Dan Roth, Chris Bruce, and Brandon Turkus talk about this year's concepts for the Easter Jeep Safari in Moab, rumors of a mid-engined Subaru sports car and the looming reveal of the next Impreza. We also cover more rumors of a simpler Acura NSX, and some other tidbits, including Ford's movie projector patent and the Opel Astra winning the European Car of the Year award. As always, we start with the Autoblog Garage and wrap up by answering your questions. Check out the rundown with times for topics, and thanks for listening! Autoblog Podcast #470 The video meant to be presented here is no longer available. Sorry for the inconvenience. Topics 2016 Easter Jeep Safari concepts Mid-Engine Subaru rumors Non-hybrid Acura NSX 2017 Subaru Impreza to be revealed at NYIAS Ford patents in-car movie projector Opel Astra is 2016 European Car of the Year In The Autoblog Garage 2016 Mercedes-Benz C450 AMG 2016 BMW X1 xDrive28i Hosts: Dan Roth, Chris Bruce, Brandon Turkus Rundown Intro and Garage – 00:00 Jeep Concepts - 21:57 Mid-Engine Subaru - 38:45 Acura NSX - 43:18 Subaru Impreza - 44:59 Ford Projector - 47:48 Astra ECOTY - 49:50 Q&A - 52:09 Total Duration: 58:11 Get The Podcast iTunes – Subscribe to the Autoblog Podcast in iTunes RSS – Add the Autoblog Podcast feed to your RSS aggregator MP3 – Download the MP3 directly Feedback Email – Podcast at Autoblog dot com Review the show in iTunes Podcasts Acura Ford Jeep Subaru Opel easter jeep safari acura nsx type r